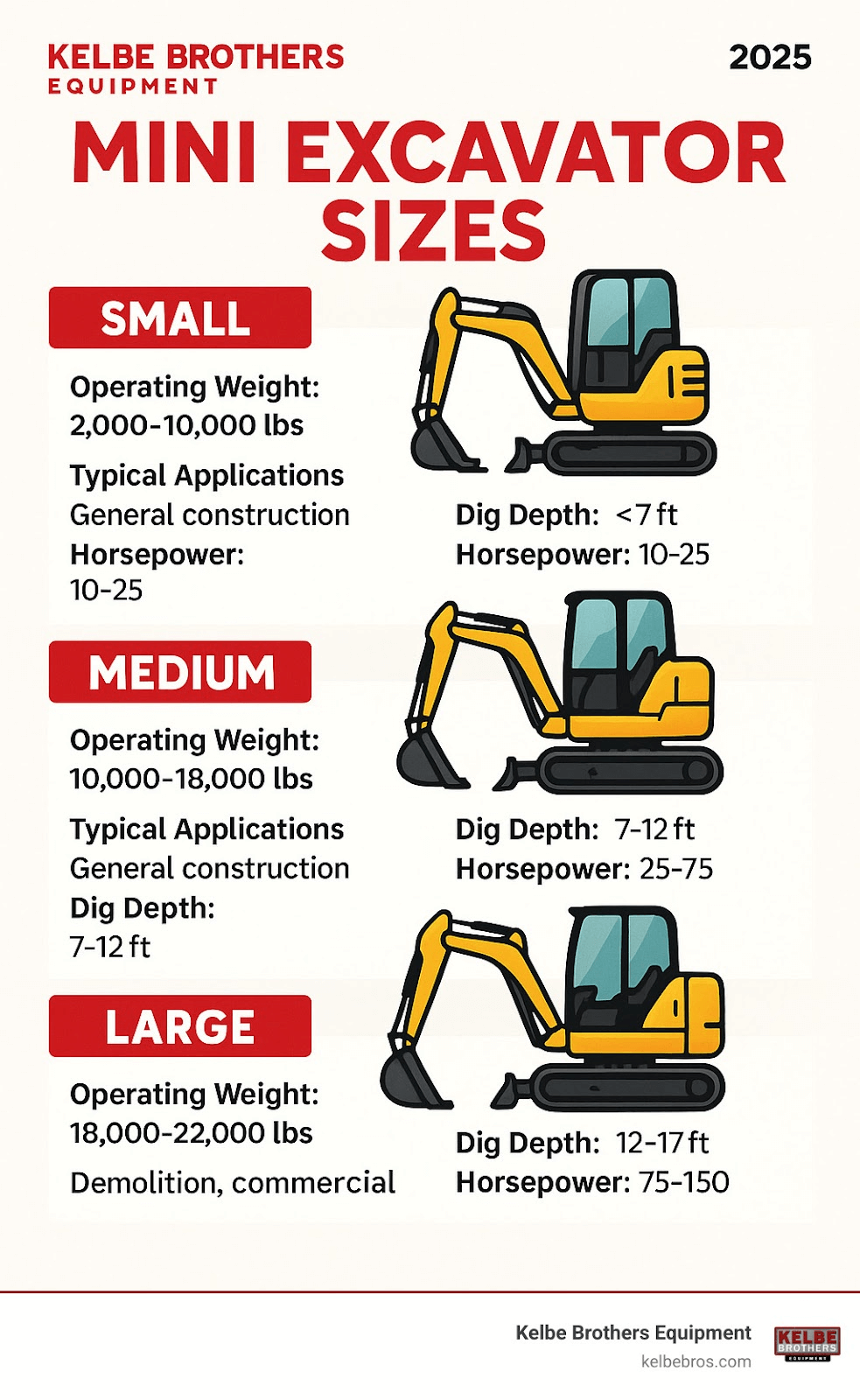

Mini excavator sizes typically range from 2,000 to 22,000 pounds and are commonly categorized into three main classes:

- Small Mini Excavators (2,000-10,000 lbs): Maximum maneuverability for tight spaces, landscaping, and utility work

- Medium Mini Excavators (10,000-18,000 lbs): Versatile all-rounders for general construction and pool installation

- Large Mini Excavators (18,000-22,000 lbs): Heavy-duty performance for demolition and commercial projects

When you’re managing a construction project in Wisconsin, choosing the wrong excavator size can mean the difference between finishing on time and dealing with costly delays. Too small, and you’ll struggle with deeper digs or heavier loads. Too large, and you might not fit through gates or work efficiently in tight spaces.

The key specs that define mini excavator sizes include operating weight, engine horsepower (ranging from 10 to 176 HP), dig depth (from 5 feet to over 17 feet), and machine width (as narrow as 28 inches for some models). These specifications directly impact what jobs each size can handle effectively.

Understanding these size categories helps you match the right machine to your specific project needs – whether you’re working on residential landscaping with a Takeuchi compact excavator, handling medium construction tasks with a New Holland mini excavator, or tackling heavy-duty jobs with a Hitachi compact excavator.

As Jeffrey J. Miller, President of Kelbe Brothers Equipment, I’ve helped Wisconsin contractors steer mini excavator sizes for over 60 years of combined industry experience. My expertise in construction equipment sizing ensures you get the right machine for maximum productivity and minimal downtime.

What is a Mini Excavator? Defining the Compact Powerhouse

Think of a mini excavator as the Swiss Army knife of construction equipment. These compact hydraulic excavators pack impressive power and precision into a smaller package than their full-sized cousins, making them perfect for Wisconsin’s diverse construction and landscaping projects.

The official classification defines mini excavators as machines up to 6 metric tons (approximately 13,200 pounds), though the reality is a bit more flexible. Manufacturers often extend this range based on what contractors actually need, which is why you’ll see mini excavator sizes ranging from tiny 1,500-pound units all the way up to hefty 22,000-pound machines.

Here’s an interesting fact that might surprise you: what truly distinguishes a mini excavator from a full-sized crawler excavator is the presence of a front dozer blade. If it has a blade, it’s classified as a mini excavator. This blade isn’t just for show either – it provides crucial stability during lifting operations and helps with backfilling and grading tasks.

Mini excavators truly shine where larger equipment simply can’t operate. Their compact design allows them to steer through standard doorways, squeeze between buildings, and access confined job sites that would be impossible for conventional excavators. Despite their smaller stature, these machines are genuine workhorses.

The magic of mini excavators comes from their rubber tracks, which minimize ground disturbance while providing excellent traction on various surfaces. This makes them ideal for landscaping projects, residential construction, and utility work where preserving existing lawns, driveways, and sidewalks is crucial.

At Kelbe Brothers Equipment, we’ve watched the construction industry increasingly rely on these compact powerhouses over our decades of service. Our Takeuchi Compact Excavators and Hitachi Compact Excavators represent the latest in mini excavator technology, offering Wisconsin contractors the reliability and performance they need for diverse projects.

You might wonder about the confusion between “mini” and “compact” excavators – and you’re not alone. Some manufacturers stick to the 6-ton limit for “mini,” while others include larger 7-8 ton machines in their mini lines due to customer demand for more capacity while maintaining transportability. The term “compact” often serves as a broader category that encompasses both mini and larger machines sharing similar traits like reduced tail swing for restrictive job sites.

Understanding the difference between mini-excavators and compact excavators helps you make informed decisions when selecting equipment for your Wisconsin projects. Whether you’re looking at excavators for sale or considering construction equipment rentals, knowing these distinctions ensures you get the right machine for your specific needs.

Understanding the Spectrum of Mini Excavator Sizes

When you compare mini excavator sizes, think of operating weight as the machine’s T-shirt size. Once you know whether you need a small, medium, or large frame—roughly 2,000-22,000 lb—you can quickly predict horsepower, dig depth, trailer needs, and attachment capacity.

Key ranges you’ll see on spec sheets:

- Operating weight: 2,000-22,000 lb

- Horsepower: 10-176 HP

- Dig depth: 5-17+ ft

- Dump height: 6-21+ ft

- Machine width: 28 in-7 ft

At Kelbe Brothers, we match those numbers to Wisconsin realities—tight urban lots in Milwaukee, soft spring soils in Madison, or long hauls up to Green Bay—so you get the right tool from our new equipment inventory.

Small Mini Excavators (Approx. 2,000-10,000 lb)

Why contractors love them

- Slip through 28-36 in gates and even doorways

- Light ground pressure keeps lawns and pavers intact

- Towable behind a ¾-ton pickup

Perfect for landscaping, indoor demolition, irrigation trenching, and tight backyard pool digs. Expect 5-10 ft dig depths and modest lift capacity.

Medium Mini Excavators (Approx. 10,000-18,000 lb)

The “Goldilocks” class rules most job sites. With 25-70 HP engines, 8-13 ft dig depths, and good stability, these machines handle about 70 % of work we see: septic systems, foundations, utility trenching, and truck loading.

Strengths

- Big enough for serious excavation

- Still nimble for urban lots

- Accept buckets, augers, breakers, thumbs

Our Hitachi excavators in this weight bracket are rental favorites because they pair productivity with easy transport on tag-along trailers.

Large Mini Excavators (Approx. 18,000-22,000 lb)

These machines stretch the word “mini” but keep compact advantages.

- 60-100+ HP, 15-17 ft dig depths

- High breakout force for demolition or heavy utility installs

- Generally legal to haul without oversize permits in Wisconsin

Ideal for commercial footings, road repairs, and deep service connections where full-size crawlers won’t fit. Our rugged Link-Belt excavators deliver the muscle without sacrificing maneuverability.

Remember: bigger isn’t always faster. A small machine that can work continuously often beats a larger unit that spends time repositioning.

Key Factors for Choosing the Right Mini Excavator Size

Choosing correctly is a three-way balance:

- Job-site limits – gate width, overhead clearance, soil support.

- Work scope – dig depth, dump height, lift capacity, attachment flow.

- Logistics – trailer ratings, haul routes, and how often you move the machine.

Oversize horsepower that sits idle wastes time; a smaller excavator that never leaves the trench keeps crews productive.

Matching Mini Excavator Sizes to Your Project’s Scope

Measure the narrowest access and the deepest required cut. A machine that can’t fit or reach comfortably is off the list. Also review:

- Clearance next to buildings or utilities

- Typical (not just maximum) dig depth

- Dump height to load your trucks

- Ground pressure limits on turf or pavement

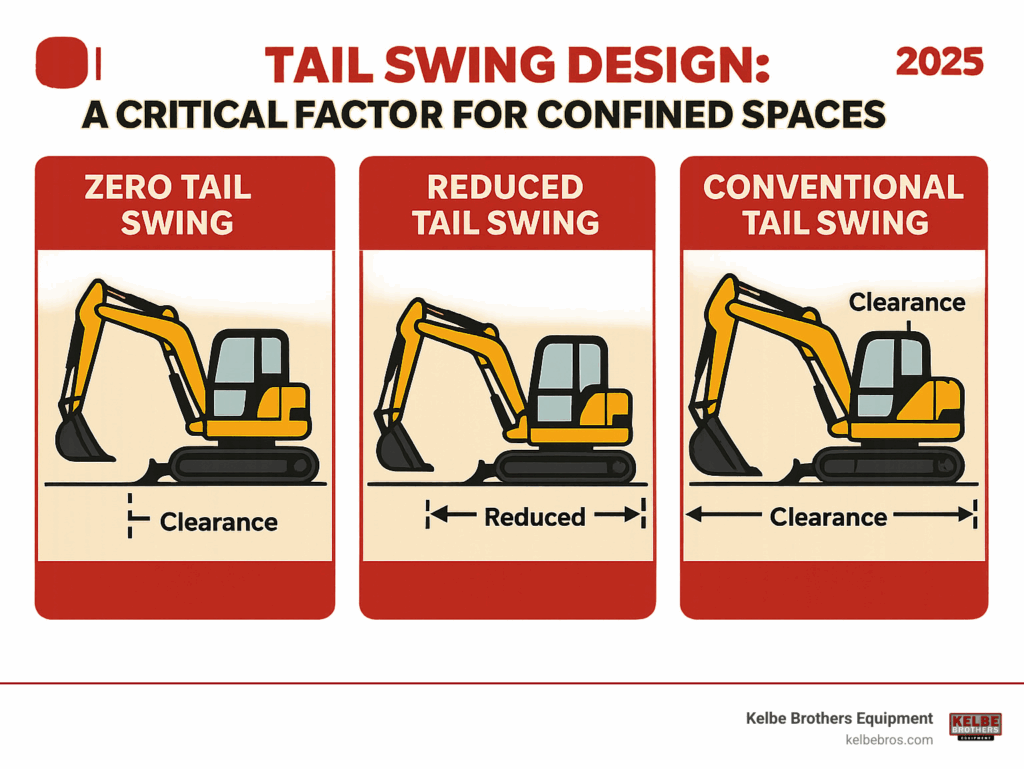

Tail Swing Design: A Critical Factor for Confined Spaces

- Zero tail swing – safest within 3 ft of obstacles.

- Reduced tail swing – compromise between clearance and capacity.

- Conventional – maximum lift force when space isn’t an issue.

Our Takeuchi Zero Swing Excavators shine on Milwaukee street projects and tight residential lots.

How Attachments Affect Mini Excavator Sizes and Capabilities

Attachments change everything. Confirm your machine’s hydraulic flow and counterweight can handle:

- Breakers, augers, grapples (check GPM/PSI)

- Added weight of thumbs or quick-couplers

- Bucket width versus trench spec

Need guidance? Call our Parts Department before you mobilize.

Transportation and Logistics

- Small minis – trailer behind a pickup, no CDL.

- Medium minis – tag-along or small low-boy behind a tandem-axle truck.

- Large minis – heavier trailer yet usually permit-free in Wisconsin.

If you shuttle between Madison, Green Bay, and Milwaukee each week, the time saved with lighter equipment may outweigh a deeper dig depth on paper.

Frequently Asked Questions About Mini Excavators

What is the most versatile mini excavator size?

When Wisconsin contractors ask me this question, I always point them toward the medium class mini excavators – those machines weighing between 10,000 and 18,000 pounds. After decades in the construction equipment business, I’ve seen these workhorses handle about 70% of typical excavation projects that come through our doors.

These machines hit the sweet spot for versatility because they offer dig depths of 8-13 feet and dump heights of 8-15 feet while still fitting on standard trailers. Their 25-70 HP engines provide enough muscle for most attachments without guzzling fuel like their bigger cousins.

What makes them truly versatile is their balanced design. They’re stable enough for serious lifting operations but still nimble enough to work in those tight residential backyards where full-sized equipment just won’t fit. Whether you’re installing a septic system, digging a foundation, or trenching for utilities, these medium mini excavator sizes can handle the job without breaking a sweat.

How do I know if I need a zero tail swing excavator?

Here’s a simple test: if you’re working within 3 feet of any obstacle – buildings, fences, parked cars, or even other equipment – you’ll want to consider a zero tail swing model. I’ve seen too many contractors learn this lesson the hard way when their conventional tail swing machine takes out a fence or scrapes a building.

Zero tail swing excavators keep their counterweight within the track width during rotation, which means no surprises behind the machine. This design is a game-changer for urban job sites, residential work, or anywhere space is tight. You’ll work faster and with more confidence when you’re not constantly worried about clearance.

The trade-off is usually some lifting capacity compared to conventional designs, but most contractors find the increased productivity from working without clearance concerns more than makes up for it. Our Takeuchi Zero Swing Excavators are particularly popular with contractors who work in established neighborhoods where every inch of clearance matters.

Does a bigger mini excavator always dig faster?

Not necessarily – and this surprises a lot of people. While bigger machines pack more power, overall efficiency depends heavily on your specific job site conditions. I’ve watched smaller, more agile machines outperform their larger counterparts in confined spaces simply because they spent less time repositioning.

Think about it this way: a machine operating at its optimal reach and angle will almost always outperform a more powerful machine that’s constantly working at the limits of its envelope. If your larger excavator has to stop and reposition every few minutes because it can’t swing freely or reach efficiently, that smaller machine that can work continuously will finish first.

Cycle time, reach efficiency, and job site logistics all factor into real-world productivity. The key is matching the machine size to your specific working conditions rather than just assuming bigger equals faster. Sometimes the most productive choice is the machine that can work steadily without interruption, even if it’s not the most powerful option on paper.

Finding the Perfect Fit for Your Wisconsin Project

Choosing the right mini excavator sizes for your Wisconsin project doesn’t have to be overwhelming. At Kelbe Brothers Equipment, we’ve been helping contractors find their perfect match for decades, and we know that every project tells its own story.

Our team starts by sitting down with you to understand what you’re really trying to accomplish. Are you digging a foundation in tight quarters? Installing utilities across varied terrain? Tackling a demolition project downtown? Each scenario demands different considerations, and we’ve seen enough projects to know which questions to ask.

Project analysis goes beyond just matching dig depth to your requirements. We look at your timeline, consider Wisconsin’s unique seasonal challenges, and factor in practical details like how you’ll transport the machine between job sites. A machine that looks perfect on paper might not work if you can’t get it to your location or if it struggles in our challenging spring soil conditions.

Productivity comes from finding that sweet spot where machine capabilities align perfectly with your specific needs. We’ve watched contractors boost their efficiency dramatically simply by switching to the right size excavator. Sometimes that means going smaller for better maneuverability, other times it means stepping up to handle heavier loads more efficiently.

Safety remains our top priority in every recommendation. Machines working within their design parameters in appropriate applications create the safest work environment. We’d rather see you use a properly sized machine that handles your job confidently than struggle with equipment that’s fighting the conditions.

Our comprehensive approach means we can support you whether you need excavators rental for short-term projects, used construction equipment for sale for budget-conscious solutions, or brand new machines from our extensive inventory. Our Service Department keeps your equipment running smoothly, while our Financing Options make ownership accessible for growing contractors.

As your New Holland dealer, Takeuchi dealer, Link-Belt dealer, and Hitachi excavator dealer, we maintain one of Wisconsin’s most comprehensive fleets. Whether you need New Holland Mini Excavators for residential work, Takeuchi Compact Excavators for versatile applications, Hitachi Compact Excavators for reliable performance, or Link-Belt Excavators for heavy-duty projects, we have the right machine waiting.

Our fourth-generation family business understands Wisconsin construction like no one else. From frozen ground conditions that test equipment limits to soft spring soils that demand careful machine selection, we know how local conditions affect equipment performance. That knowledge guides every recommendation we make.

The construction equipment rentals and construction equipment for sale we offer come with the backing of our experienced team and 24/7 emergency support. When project timelines get tight or unexpected challenges arise, we respond quickly with solutions that keep your work moving forward.

Ready to find your perfect match? Explore our new equipment inventory or give us a call to discuss your specific requirements. With our extensive experience and locations throughout Wisconsin, we’re here to ensure you get exactly the right machine for maximum productivity and project success.