DEF compatible materials are specifically engineered components that store, transport, and dispense Diesel Exhaust Fluid without degrading it or contaminating your system. When choosing parts for your DEF setup, you need materials that won’t react with the urea solution or compromise your equipment’s Selective Catalytic Reduction (SCR) system.

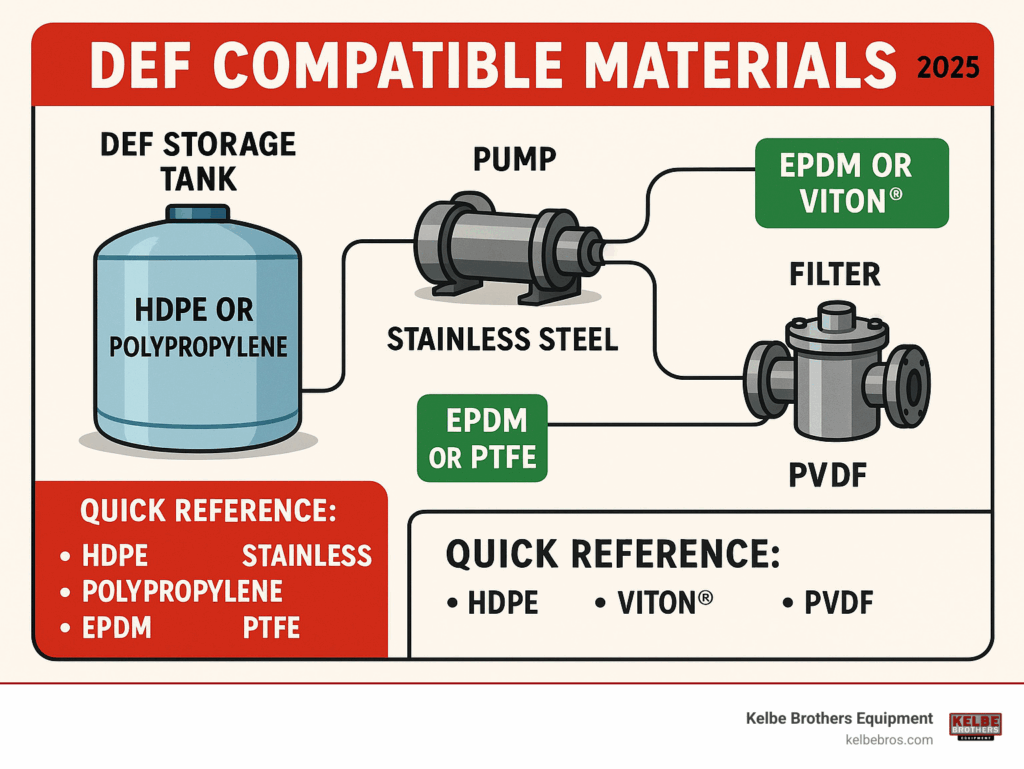

Quick Reference: DEF Compatible Materials

- Recommended Plastics: HDPE, Polypropylene, PVDF, PFA, PTFE

- Compatible Metals: Stainless Steel (304, 304L, 316, 316L), Titanium, Hastelloy

- Safe Elastomers: EPDM, FKM (Viton®), FFKM

- Avoid These Materials: PVC, Aluminum, Copper, Zinc, Carbon Steel, Buna-N

Modern machines like Hitachi wheel loaders, Takeuchi compact track loaders, and New Holland mini excavators rely on clean DEF to meet emissions standards. Incompatible materials can trigger failures, contaminate your DEF, and sideline your fleet when you need it most.

The stakes are high. As one industry expert notes: “Maintaining Diesel Exhaust Fluid (DEF) purity and cleanliness according to the specifications defined by ISO 22241 is essential in preventing damage to the Selective Catalytic Reduction (SCR) aftertreatment system.”

I’m Jeffrey J. Miller, President of Kelbe Brothers Equipment, and I’ve seen how overlooking DEF compatible materials can shut down large-scale construction projects. Over our 60+ years in the industry, we’ve helped contractors avoid those setbacks by understanding material compatibility from the ground up.

What is DEF and Why is Material Compatibility So Crucial?

Think of Diesel Exhaust Fluid as your equipment’s environmental superhero. This carefully balanced mixture contains 32.5% high-purity synthetic urea and 67.5% deionized water that gets injected into your exhaust stream. Inside the SCR catalyst system, this humble solution performs an amazing change—turning harmful nitrogen oxides (NOx) into harmless nitrogen and water vapor.

But DEF can be surprisingly aggressive when it meets the wrong materials. The solution may look like water, yet it can corrode certain metals, break down incompatible plastics, and become contaminated quickly.

Trouble starts when DEF encounters materials it doesn’t like. Urea reacts with metals such as aluminum and copper, releasing ions that poison your SCR catalyst. Some plastics deteriorate, shedding particles that clog injectors and damage pumps. For fleets running Takeuchi excavators or New Holland wheel loaders, that’s the difference between steady progress and unexpected downtime.

The High Cost of Contamination—Without Mentioning Dollars

Contaminated DEF can take down an SCR system, halt productivity, and generate cascading delays. The ISO 22241 standard exists because even trace contamination can trigger major failures. When you manage construction equipment for sale or operate a fleet of Link-Belt excavators, those standards protect your schedule as much as your machinery.

How Incompatible Materials Wreak Havoc

When DEF touches incompatible metals, galvanic corrosion begins. Incompatible plastics create swelling and surface breakdown, releasing debris that moves downstream. Contaminated DEF clogs filters, disrupts DEF injection, and triggers emissions faults that can reduce engine power or shut down equipment altogether. For New Holland skid steer loaders and any modern diesel machine, material choice directly affects daily reliability.

The Ultimate Guide to DEF Compatible Materials

This section breaks down materials suitable for every part of your DEF storage and handling system, from large tanks to the smallest seals. Using the right materials is the first line of defense for Takeuchi excavators and New Holland mini excavators alike.

Recommended Plastics for Tanks and Fittings

High-Density Polyethylene (HDPE) is the go-to choice for most DEF storage tanks. This material shows excellent chemical resistance with minimal swelling when exposed to DEF and maintains its strength whether your DEF freezes at 12 °F or sits in storage at 86 °F.

Polypropylene (PP) works well for fittings and smaller components, offering the same reliable compatibility.

For contractors who need improved performance, Polyvinylidene Fluoride (PVDF) provides superior chemical resistance and temperature stability. At the top end, Perfluoroalkoxy Alkane (PFA) and Polytetrafluoroethylene (PTFE) deliver virtually universal chemical resistance for critical applications.

Important: specify additive-free grades. Stabilizers and colorants in some plastics can leach into DEF and create contamination.

Critical Gasket and Seal Materials for DEF Systems

EPDM (Ethylene Propylene Diene Monomer) elastomers are the workhorses of DEF sealing applications, showing less than 15 % swelling when exposed to DEF.

FKM (Viton®) offers outstanding chemical resistance and temperature stability. For the most demanding scenarios, FFKM (Perfluoroelastomer) delivers near-universal chemical resistance and long service life.

Never use Buna-N (Nitrile) seals in DEF systems. They swell and deteriorate quickly, introducing contaminants that can damage the entire SCR system.

Keep DEF-rated elastomer grades on hand with our Parts services so your fleet stays on the job.

Metals in Your DEF System: A Guide to DEF Compatible Materials

| Material | Compatibility | Rating | Notes |

| Stainless Steel 316 | Excellent | A | Preferred for fittings and components |

| Stainless Steel 304 | Excellent | A | Proven, general-purpose choice |

| Titanium | Excellent | A | Exceptional durability |

| Hastelloy | Good | B | For specialized applications |

| Aluminum | Not Compatible | — | Severe corrosion risk |

| Copper | Not Compatible | — | Catalyst poisoning risk |

| Zinc | Not Compatible | — | Rapid degradation |

| Carbon Steel | Not Compatible | — | Corrosion and contamination |

Stainless steel grades 304, 304L, 316, and 316L resist corrosion from the urea solution and avoid introducing harmful ions. Titanium and Hastelloy provide additional defense for specialized parts.

Avoid aluminum, copper, brass, zinc, and carbon steel. These metals corrode in DEF, releasing ions and particles that damage pumps, filters, and SCR catalysts.

Explore compatible components through our New Equipment inventory to ensure every machine in your fleet stays compliant and productive.

Factors Influencing Material Choice and System Longevity

Choosing the right material is only part of the equation. Environmental conditions and maintenance practices also determine how long your DEF system will serve fleets that include construction equipment rentals and owned machinery.

How Temperature Affects DEF Material Compatibility

Temperature is one of the most critical factors in DEF system design. DEF freezes at 12 °F (-11 °C) and expands about 7 % when it turns to ice. That expansion can crack incompatible materials or stress system components.

Freeze-thaw cycles are especially challenging for seals. EPDM and FKM elastomers remain flexible and maintain sealing properties even after repeated freezing and thawing.

At the other end of the spectrum, DEF begins to decompose around 140 °F (60 °C), forming deposits that clog injectors and damage pumps. Proper storage temperatures between 12 °F and 86 °F preserve DEF quality.

The ISO 22241-4:2019 standard outlines temperature guidelines that help your Hitachi wheel loaders and other machines operate flawlessly in extreme climates.

Best Practices for Selecting and Maintaining DEF Equipment

Proper material selection is only the beginning. Ongoing maintenance keeps DEF systems reliable:

- Dedicated Equipment Principle: Use storage tanks, pumps, hoses, and dispensing equipment reserved for DEF only.

- Filtration: Employ 1-micron filter cartridges at storage and dispensing points.

- API Certification: Purchase DEF that carries the API Certification Mark to ensure ISO 22241 compliance.

- Cross-Contamination Prevention: Color-code and label DEF handling equipment; train staff thoroughly.

- Regular Inspection: Check for corrosion, leakage, or contamination.

- System Cleaning: Flush and clean systems when changing components or fluid.

Our Service and Best Practices resources help Wisconsin contractors keep their fleets—whether Takeuchi compact excavators or New Holland tractor loader backhoes—running without interruption.

Frequently Asked Questions about DEF Materials

Can I use a regular diesel or fuel container to store or transport DEF?

No. Fuel containers are made for hydrocarbons, not aqueous urea solutions. Using a non-dedicated container introduces chemical residues that contaminate DEF and damage SCR systems. Always use containers made from approved materials such as HDPE, clearly marked for DEF.

What happens if I use a fitting made from PVC or brass?

PVC degrades in DEF, releasing particles into the fluid. Brass corrodes and releases copper ions that poison the SCR catalyst. Either mistake can disable equipment like Link-Belt excavators or Hitachi excavators. Use stainless steel 304/316 or other approved materials instead.

Why is stainless steel recommended for DEF systems?

Austenitic stainless steels, especially grades 304 and 316, are essentially inert to DEF. They resist corrosion, avoid leaching harmful ions, and preserve DEF purity—exactly what your Hitachi wheel loaders and Takeuchi compact excavators need for long-term reliability.

Selecting stainless steel components helps maintain DEF quality and protects sensitive SCR catalysts from premature failure.

Protect Your Investment with the Right Knowledge

Your DEF-compatible materials choices today determine whether your equipment runs smoothly tomorrow or sits idle in the shop. After four generations in Wisconsin’s construction equipment industry, Kelbe Brothers Equipment knows that the smallest details often make the biggest difference.

Every component in your DEF system—from a 100-gallon storage tank down to a single O-ring—either safeguards your equipment or threatens it. The urea solution does not compromise, and neither should you.

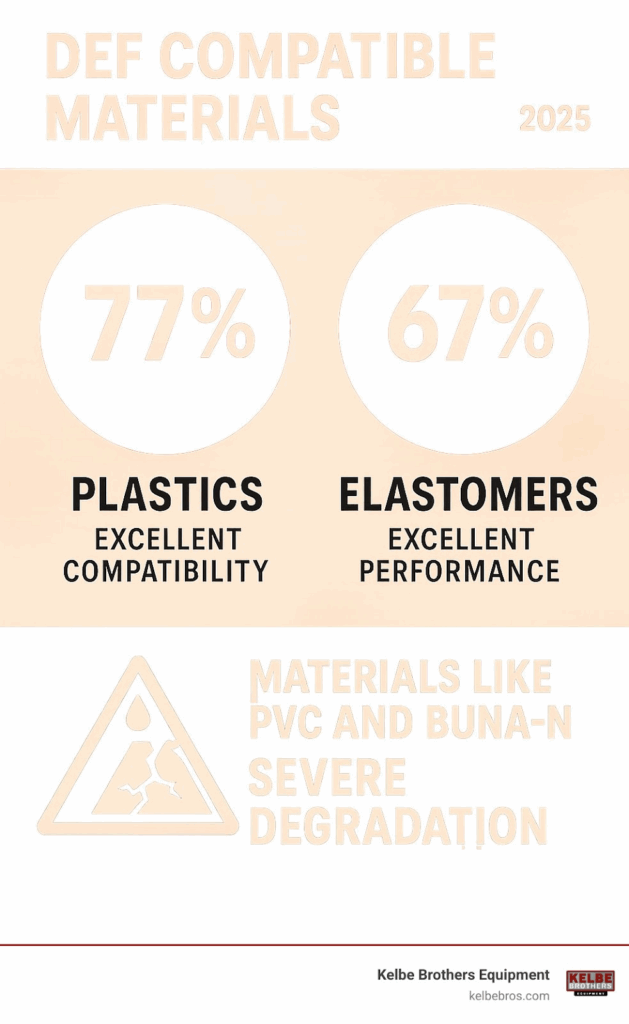

Research shows that 77 % of plastics and 67 % of elastomers perform excellently when properly selected for DEF service. Choosing from the wrong subset, however, can damage an SCR system faster than you might imagine.

We’ve seen contractors learn this lesson the hard way. A simple PVC fitting or a Buna-N seal can swell, crack, and contaminate your DEF, leading to unplanned downtime that disrupts entire job sites.

Your fleet—whether Takeuchi compact track loaders, New Holland crawler dozers, or Hitachi wheel loaders—deserves better protection. Modern diesel engines depend on clean DEF to meet emissions standards, and clean DEF depends on compatible materials throughout the system.

The formula for success is straightforward:

- Use approved plastics like HDPE, polypropylene, and PVDF for tanks and fittings.

- Choose EPDM or FKM elastomers for seals and gaskets.

- Select stainless steel 304 or 316 for metal components.

- Avoid aluminum, copper, zinc, PVC, and Buna-N materials.

Combine these choices with strict contamination-prevention protocols and adherence to ISO 22241 standards. At Kelbe Brothers Equipment, our experienced team supports local contractors with parts, service, rentals, and expert guidance.

Learn more about our Best Practices for equipment maintenance and give your valuable construction equipment the protection it deserves—because when you choose the right materials from the start, your machines keep working while others wait in the repair bay.