A compact excavator is a small but powerful earthmoving machine weighing between 0.7 to 8.5 tons, designed for versatility and operation in confined spaces where larger equipment cannot access. These mini powerhouses deliver impressive performance while maintaining maneuverability.

Quick Guide to Compact Excavators:

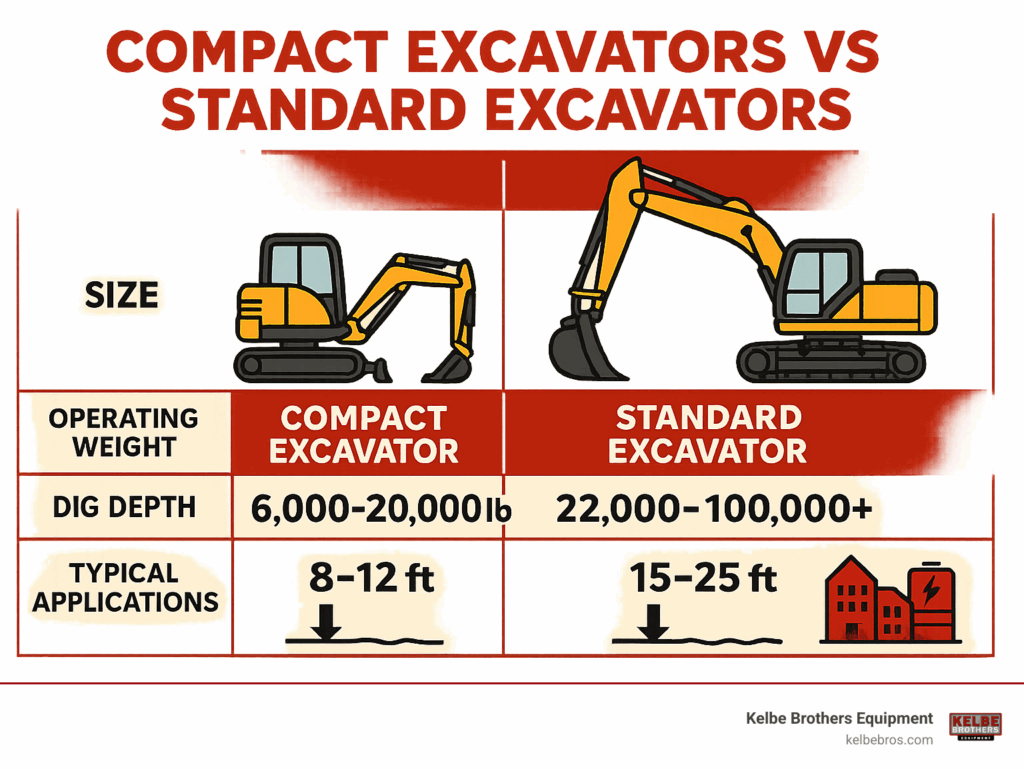

- Weight Range: 0.7 to 8.5 tons (1,700 to 18,500 lbs)

- Dig Depth: 4.5 to 15+ feet, depending on model

- Key Benefits: Tight space accessibility, lower transport costs, versatile attachments

- Popular Brands: Hitachi, Link-Belt, Takeuchi, New Holland

- Zero-Tail Swing: Available on many models for working near walls/structures

- Typical Applications: Landscaping, utility installation, residential construction

In the competitive world of construction and landscaping, compact excavators have become indispensable tools for contractors seeking to maximize productivity in tight spaces. These machines pack remarkable power and versatility into a small footprint, making them ideal for urban jobsites, residential work, and projects with limited access.

Today’s compact excavators offer advanced features like zero-tail swing designs, spacious cabs with ergonomic controls, and fuel-efficient engines that deliver full-size performance without the bulk. Whether you’re digging trenches for utility lines, preparing foundations, or handling precise landscaping tasks, a well-chosen compact excavator can dramatically improve your efficiency and capability.

I’m Jeffrey J. Miller, President of Kelbe Brothers Equipment, where I’ve guided our company through industry transitions while expanding our compact excavator offerings to meet the evolving needs of Wisconsin contractors. My experience with compact excavator selection, application, and service has shown me how these versatile machines can transform productivity on challenging job sites.

The Case for Going Compact

Let’s face it—sometimes the best things really do come in smaller packages, especially when you’re squeezing equipment through a backyard gate or working alongside a busy downtown sidewalk. Today’s compact excavators are proving that point on jobsites across Wisconsin.

Tight Space Champions

I’ve watched contractors light up when they realize what a compact excavator can do in places where traditional machines simply can’t go. With widths starting at just 2’4″ on the smallest models and typically under 6’7″ for mid-sized units, these nimble machines slip through narrow passages that would stop larger equipment in its tracks.

Picture this: a residential backyard renovation where the only access is through a garden gate, or a utility repair between established buildings downtown. In these scenarios, a compact excavator isn’t just convenient—it’s often the only mechanical solution that prevents hours of backbreaking manual labor.

Reduced Tail Swing = Reduced Risk

One of my favorite features to show customers at Kelbe Brothers is the zero and minimal tail swing design on modern compact excavators. This brilliant innovation virtually eliminates that heart-stopping moment when the back end swings into a wall or fence.

While conventional excavators typically measure about 60 inches wide, their zero-swing cousins might be slightly wider at around 70 inches, but they offer dramatically improved safety when working in tight quarters. For utility contractors threading between gas lines or landscapers working near a client’s prized Japanese maple, this feature alone can save thousands in potential damage.

Fuel Efficiency That Adds Up

When I talk with contractors about operating costs, the fuel efficiency of today’s compact excavators often surprises them. Modern machines come equipped with smart features that weren’t available even a few years ago:

- ECO modes that can improve fuel economy by up to 9%

- Auto-deceleration systems that reduce engine RPMs during idle periods

- Load-sensing hydraulics that adjust flow based on demand

These aren’t just marketing points—they translate to real savings that compound with every hour of operation. Plus, reduced emissions are increasingly important for meeting municipal requirements and satisfying environmentally-conscious clients.

Lower Ground Pressure, Less Site Damage

There’s nothing worse than finishing a beautiful landscaping job only to leave behind a maze of ruts and damaged turf. The lighter weight of compact excavators (typically between 1.7 to 6 metric tons) means significantly less ground pressure compared to standard machines.

Many models feature rubber tracks as standard equipment, further reducing their footprint on delicate surfaces. Some even offer retractable undercarriages that expand for stability during operation and contract for passage through tight spaces—perfect for getting through a garden gate before widening out to work safely.

The OSHA excavation standards at https://www.osha.gov/excavation-standards underscore the importance of safety in confined digging operations, where compact excavators excel by reducing many common hazards through their improved visibility and maneuverability.

When you combine these benefits—maneuverability in tight spaces, reduced risk of collisions, better fuel economy, and minimal site damage—it’s easy to see why compact excavators have become essential tools for Wisconsin contractors who want to work smarter, not harder.

Top Compact Excavator Models for 2025

Looking for the perfect compact excavator for your next project? As we help Wisconsin contractors find equipment that matches their unique challenges, we’ve had our hands on the controls of dozens of machines. Here are the standouts that our customers keep coming back to in 2025:

Hitachi ZX-5 Series Compact Excavator

There’s something special about climbing into the seat of a Hitachi ZX26U-5N. This 5,900-pound workhorse has become a favorite among our customers who need precision in tight spaces.

With its ultra-tight 9’2″ tail swing radius, you can work confidently next to buildings without worrying about costly bumps and scrapes. The 20 HP engine delivers surprising punch while being miserly with fuel, especially with the smart auto-idle feature that kicks in when you’re planning your next move.

What really makes operators smile is the 8’6″ dig depth combined with the hydraulic quick-coupler system. One minute you’re precision digging, the next you’ve swapped to a breaker attachment – all without leaving the comfort of the surprisingly spacious cab with its excellent visibility.

As Hitachi excavator dealers, we’ve watched these machines rack up thousands of hours while maintaining their smooth, precise control. The ZX-5 Series hydraulics deliver the finesse needed for delicate work alongside the raw power for tough Wisconsin soil conditions.

Link-Belt X3E Series Compact Excavator

When customers tell us they need a machine that can take a beating day after day, we often point them toward the Link-Belt excavators in the X3E Series. These machines have earned their reputation through thoughtful engineering and battlefield toughness.

The minimal tail swing design means you can work closer to obstacles without constant worry, while the reinforced undercarriage with sealed track rollers shrugs off the punishment of rocky terrain. Operators particularly appreciate the proportional auxiliary control that delivers precise hydraulic flow to attachments.

What sets the X3E Series apart is its rock-solid stability even when working at reach. This confidence-inspiring steadiness means you can safely handle heavier loads without the tippy feeling that plagues some compact machines. From frozen January job sites to muddy April conditions, these machines take Wisconsin’s challenging ground conditions in stride.

Takeuchi Zero-Swing Compact Excavator

The Takeuchi TB257FR is what happens when engineers refuse to compromise. This remarkable 12,500-pound compact excavator delivers true zero tail swing combined with a side-to-side offset boom that allows the entire machine to work within its own footprint.

Imagine digging parallel to a foundation wall with absolute precision – that’s where this machine shines brightest. With its impressive 12’9″ dig depth and long-arm configuration, you’ll spend less time repositioning and more time moving dirt.

The 39 HP Tier 4 Final engine delivers the power you need, while the auto-idle and ECO mode features keep fuel costs in check. As authorized Takeuchi dealers, we’ve heard consistent praise from contractors who initially chose this machine for its maneuverability but fell in love with its power and versatility. The industry-leading 4-year/4,000-hour warranty coverage doesn’t hurt either!

New Holland E37C Compact Excavator

From the renowned 200-Series DNA, the New Holland mini excavator E37C packs serious capability into its 3.7-ton frame. With a dig depth of 10’10”, it hits the sweet spot for utility work and general construction tasks.

Operators particularly appreciate the two-speed travel system that automatically downshifts under load – a small but meaningful feature when you’re navigating across larger job sites. The spacious comfort cab keeps productivity high with excellent visibility and ergonomic controls that reduce fatigue during long shifts.

What makes the E37C a versatile addition to any fleet is its high auxiliary flow rates, powering everything from hydraulic hammers to augers with authority. And the pattern control selector is a thoughtful touch, allowing operators to quickly switch between ISO and SAE controls based on personal preference.

As your local New Holland dealer, we’ve seen how these machines combine day-in, day-out reliability with the comfort features that keep your team productive from sunup to sundown.

How to Choose the Right Compact Excavator

Finding your perfect compact excavator match doesn’t have to be complicated. At Kelbe Brothers Equipment, we guide Wisconsin contractors through this decision every day, helping them balance capabilities, transport needs, and budget considerations.

Size Classes: Finding Your Sweet Spot

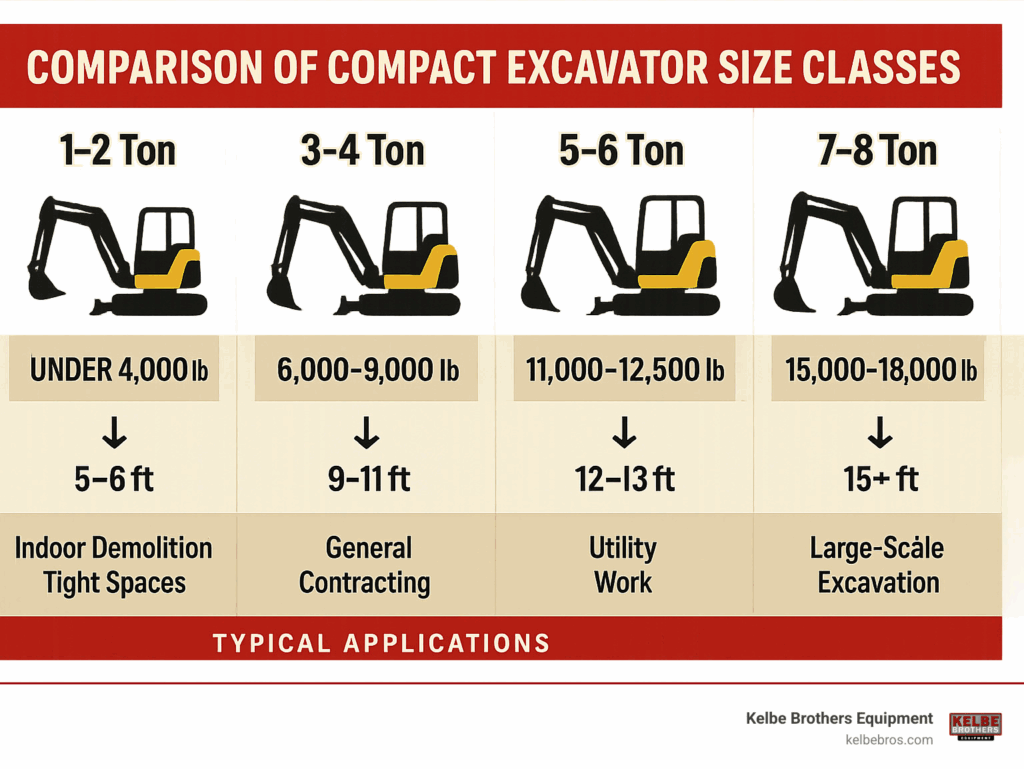

The world of compact excavators spans from nimble 1-ton machines to powerful 8-ton workhorses. Each class brings distinct advantages:

The 1-2 ton lightweights shine in indoor demolition and tight residential spaces, digging down 5-7 feet while staying under 4,000 pounds. Our 3-4 ton models represent the “Goldilocks zone” for many contractors—not too big, not too small—offering dig depths around 9-11 feet with reasonable 6,000-9,000 pound weights.

For more demanding jobs, our 5-6 ton compact excavators deliver deeper digs (11-12 feet) and greater lifting power while remaining trailer-friendly. At the top end, 7-8 ton machines approach mid-size excavator capabilities with 15+ foot dig depths, yet maintain the compact advantages you need.

When we help you select your size class, we always look beyond today’s jobs to where your business is heading in the next few years. Sometimes, that slightly larger machine proves to be the smartest long-term investment.

Transport Considerations

Before falling in love with any compact excavator, let’s have an honest conversation about how you’ll move it between job sites. Can your current truck and trailer handle the weight? Will you need a CDL for the combined weight? How often will you squeeze through narrow access points?

For tight-access specialists, we recommend models with retractable undercarriages—these clever machines can shrink down to just 28 inches wide for doorway access, then expand for rock-solid stability once they’re in position. It’s like having two machines in one.

Match Specs to Tasks — The “Goldilocks” Compact Excavator

Finding your perfect compact excavator means matching machine capabilities to your everyday work. Utility contractors need sufficient dig depth for code-compliant pipe installation, while landscapers might prioritize reach over maximum depth.

Wisconsin’s challenging clay soils demand serious bucket and arm breakout force. If you’re frequently running hydraulic attachments like breakers or augers, we’ll make sure your machine delivers adequate flow rates and pressure to power them effectively.

Don’t overlook lift capacity when comparing models. We carefully explain both over-front and over-side capacities, particularly important if you’re placing heavy materials like concrete pipes or boulder features. Manufacturers rate maximum loads at 87% of hydraulic capacity or 75% of tipping capacity—whichever is lower.

Future-Proof Your Fleet with Telematics

Today’s compact excavators are smarter than ever, with telematics systems that transform how you manage your equipment. These intelligent systems alert you to maintenance needs before they become expensive problems, track machine location with geo-fencing capabilities, monitor fuel consumption, and deliver usage data for precise job costing.

The good news? Many of our Hitachi, Link-Belt, Takeuchi, and New Holland models include complimentary telematics subscriptions for the first few years of ownership. Some even offer five years of free service, delivering significant value and peace of mind. Learn more about keeping your machine in peak condition by visiting our Parts department.

As your trusted equipment partner across Wisconsin, the Kelbe Brothers team helps you steer these considerations to find not just any compact excavator, but the perfect match for your specific needs, working conditions, and growth plans.

Attachments & Versatility That Multiply ROI

The true magic of compact excavators happens when you expand their capabilities with attachments. What starts as a digging machine can transform into a multi-talented worksite partner that handles dozens of specialized tasks, all without buying separate equipment for each job.

Quick-Couplers: The Game Changer

Nothing has revolutionized compact excavator productivity quite like quick-coupler systems. These ingenious devices let operators swap attachments in minutes or even seconds, often without leaving the comfort of their cab.

“The right quick-coupler can easily save an hour of productive time each day,” says our equipment specialist, Tom. “That’s five hours a week you’re working instead of swapping attachments—time that goes straight to your bottom line.”

Most Takeuchi compact excavators and Hitachi excavators we supply come pre-plumbed for hydraulic quick-couplers, making future upgrades straightforward. You can start with a basic mechanical system (affordable and reliable, though requiring manual pin securing) and later upgrade to a fully hydraulic system that lets you change attachments with the push of a button.

For contractors looking for the ultimate in versatility, tilt couplers add side-to-side movement for precise grading work, while tiltrotators—the Swiss Army knife of excavator attachments—enable full 360° rotation of whatever tool you’ve attached.

Must-Have Attachments for Maximum Versatility

Beyond standard digging buckets, the right mix of attachments can dramatically expand what your compact excavator can accomplish. Specialized buckets like extra-narrow cemetery buckets make precision work a breeze, while skeleton buckets let you separate materials right on site. For finishing work, a wide grading bucket with a straight edge creates smooth, even surfaces.

Hydraulic thumbs quickly pay for themselves in material handling efficiency—whether you’re placing landscape boulders, removing debris, or positioning pipes. For contractors who install fencing, plant trees, or build foundations, an auger attachment eliminates the need for separate drilling equipment.

Need to break up concrete, asphalt, or rock? A breaker/hammer attachment turns your excavator into a focused demolition machine. For land clearing and brush management, grapples and brush cutters transform your compact excavator into a vegetation management system that makes quick work of overgrown areas.

The Tiltrotator Revolution

The game-changing attachment that’s reshaping how contractors think about compact excavators is undoubtedly the tiltrotator. These sophisticated tools combine tilting and rotating functions, allowing operators to position buckets and other attachments at virtually any angle without moving the machine itself.

“A tiltrotator can reduce machine repositioning by up to 70%,” explains our equipment specialist. “Think about that—on tasks like precision grading or pipe laying, you’re working instead of maneuvering three-quarters of the time you’d normally spend repositioning.”

While the initial investment is substantial, contractors who regularly perform precision work often see payback periods of less than a year through dramatically improved productivity. One landscaping customer told us his tiltrotator-equipped Takeuchi compact excavator now completes complex grading jobs in about half the time of his previous method.

Auxiliary Hydraulic Considerations

To get the most from your attachments, your compact excavator’s hydraulic system needs to be up to the task. Modern machines typically feature a primary auxiliary circuit that powers most attachments and should offer adjustable flow rates for different tools. For attachments requiring multiple functions, a secondary circuit becomes essential.

Many of the New Holland mini excavators and Hitachi excavators we supply feature digital control panels that allow operators to store flow settings for different attachments, eliminating the guesswork when switching between tasks.

At Kelbe Brothers Equipment, our service team can help configure your machine’s hydraulic system to perfectly match your attachment needs, ensuring optimal performance and longevity. With our 24/7 emergency support, you’ll minimize downtime even if issues arise, because we understand that in construction, time truly is money.

Own It or Rent It? Keeping Cash Flow Healthy

Let’s talk about one of the toughest decisions you’ll face when considering a compact excavator – should you buy it or rent it? I’ve seen contractors wrestle with this question for years, and there’s no one-size-fits-all answer. Your specific situation will determine which path makes the most financial sense.

The Ownership Advantage

There’s something deeply satisfying about owning your equipment. When you purchase a compact excavator, you’re building equity in a valuable asset that can serve your business for years to come. Ownership makes perfect sense when:

You find yourself needing the machine consistently throughout the year, typically 50+ days annually. At this usage level, the math starts tipping heavily in favor of ownership.

You’ve experienced the frustration of not having equipment available exactly when you need it. Owning means no more waiting for rentals during the busy season when everyone else needs one too.

Your work requires specialized attachments or custom configurations that rentals might not offer. With your own machine, you can set it up exactly how you need it.

Today’s compact excavators are built to last, with many models easily surpassing 5,000 operating hours when properly maintained. This impressive longevity helps spread your initial investment across many projects, steadily reducing your per-hour operating cost over the machine’s lifetime.

When a Rental Compact Excavator Makes Sense

On the flip side, renting a compact excavator can be the smarter financial move when:

Your need for the machine comes and goes with seasonal work or specific projects. Why carry the cost of ownership during months when the machine sits idle?

Your projects vary significantly in scope, sometimes requiring a 2-ton machine and other times needing a 5-ton powerhouse. Renting gives you the flexibility to always have the right-sized tool for the job.

You’re still testing the waters with certain types of work and want to evaluate different machines before committing to a purchase.

You’re working with limited storage space or don’t have the right transport equipment to move a machine between job sites.

At Kelbe Brothers, our rental fleet includes a wide range of Hitachi compact excavators, Link-Belt excavators, Takeuchi compact excavators, and New Holland mini excavators to match your specific project requirements. With our locations across Wisconsin – including Milwaukee, Madison, Green Bay, Butler, and De Pere – we can quickly get the right machine to your jobsite when you need it.

Utilization Rate: The Key Metric

When you’re crunching the numbers, focus on your utilization rate – how many days per year you’ll actually put the machine to work. As a rule of thumb:

Less than 40 days per year: The rental option typically makes more financial sense.

40-60 days per year: You’re in the “breakeven zone,” where other factors become decisive, like how critical immediate availability is to your business.

More than 60 days per year: Ownership usually provides better long-term value.

These thresholds can shift based on your specific situation, including local rental rates, available financing terms, and your business model.

Financing & Used Options for Long-Term Value

If ownership is your path forward, we offer flexible financing solutions custom to your business needs. Our options include traditional equipment loans, leases with purchase options, and even seasonal payment structures that align with your cash flow patterns.

For many of our customers, well-maintained used compact excavators offer an excellent balance of capability and affordability. Every used machine in our inventory undergoes thorough inspection and servicing before sale, ensuring you get reliable performance without paying the new-equipment premium.

When evaluating a used compact excavator, pay close attention to:

Operating hours (4,000-5,000 hours is considered moderate usage), maintenance history documentation, undercarriage condition (often the most expensive wear item), and hydraulic performance.

With our fourth-generation family business experience dating back to 1929, we’ve helped countless Wisconsin contractors steer these decisions. Whether you’re looking for a new equipment purchase, a quality used machine, flexible financing options, or a hassle-free rental, we’re here to help you find the solution that keeps your cash flow healthy while meeting your equipment needs.

Frequently Asked Questions about Compact Excavators

What maintenance schedule keeps a compact excavator running past 5,000 hours?

Keeping your compact excavator running strong well beyond the 5,000-hour mark isn’t complicated, but it does require consistency. Think of it as regular health check-ups for your machine.

Start with daily walkarounds before firing up the engine—check fluid levels, look for leaks, inspect track tension, and hit those grease points. These quick five-minute checks can prevent major headaches down the road. At the 50-hour mark, give all pins and bushings a thorough greasing to keep movement smooth and prevent premature wear.

When you hit 250 hours, it’s time for that engine oil and filter change, along with a thorough inspection of your hydraulic system. At 500 hours, replace those hydraulic and fuel filters, and make sure your cooling system is in top shape. The big 1,000-hour service is when you’ll want to change the hydraulic oil, inspect track drive motors, and check the swing bearing.

I’ve noticed many of our customers are pleasantly surprised that newer compact excavators have extended service intervals compared to machines from just a decade ago. Some manufacturers now recommend oil changes at 500 hours instead of 250—that’s a significant time and cost savings over the life of your machine.

Your hydraulic system is the heart of your excavator. Clean oil and properly functioning filters prevent costly damage to pumps, valves, and motors—components that can make you wince when you see the repair bill.

At Kelbe Brothers, we can help you create a maintenance schedule custom to your specific machine and how you use it. We’ve seen how regular maintenance turns a 5,000-hour machine into a 10,000-hour workhorse.

How do I know if a compact excavator can be towed by my truck?

This is one of the most common questions we get, and it’s an important one for safety and legal reasons. Transporting a compact excavator requires getting several numbers right.

First, add up the total package: excavator weight + trailer weight + any attachments you’re bringing along. Then check your truck’s actual towing capacity (not just what the hitch is rated for) and make sure your trailer can handle the load. Don’t forget about tongue weight, which typically runs 10-15% of your total trailer weight and directly impacts your truck’s rear suspension and handling.

For reference, here’s what you can expect weight-wise with common compact excavator classes:

- 1-ton class machines typically weigh 2,000-3,800 lbs

- 1.5-2 ton class runs 3,800-6,000 lbs

- 2.5-3 ton class hits 6,000-10,000 lbs

- 3.5-4 ton class falls between 7,500-9,000 lbs

- 4.5-5 ton class weighs 10,000-11,000 lbs

- 5.5-6 ton class tops out at 12,000-13,500 lbs

Most states require trailer brakes when your combined weight exceeds 3,000 pounds. And if your truck, trailer, and load combination exceeds 26,000 pounds GVWR, you’ll likely need a CDL.

I remember a customer who thought his half-ton pickup could handle a 3-ton excavator because the dealer who sold him the truck bragged about its towing capacity. We helped him find a more appropriate transport solution before he learned the hard way on a steep Wisconsin hill.

If you’re unsure about your setup, give us a call. We’re happy to evaluate your current transport capabilities and can recommend solutions from trailer upgrades to our delivery service.

Which attachments add the most versatility for landscaping work?

After 40 years in this business, I’ve watched landscapers transform what they can accomplish with the right compact excavator attachments. If you’re looking to maximize versatility, these five attachments consistently deliver the biggest bang for your buck:

A grading bucket is your finishing tool—wider than standard buckets with a straight cutting edge that makes final grading and slope work look like art instead of excavation. Pair that with a hydraulic thumb and you’ve got the perfect setup for placing boulders, removing stumps, and handling materials with surgical precision.

For landscapers who regularly install trees, fences, or hardscape elements, an auger attachment quickly pays for itself by creating perfect holes for plantings, posts, and footings in minutes rather than hours of manual labor.

The game-changer I’ve seen transform landscaping businesses is the tiltrotator. Yes, it’s a significant investment, but the ability to precisely grade and place materials at literally any angle without repositioning your machine can cut project times dramatically. I’ve had customers tell me their tiltrotator paid for itself in just one season of work.

For property maintenance and land clearing, a brush cutter attachment turns your excavator into a vegetation management system that can handle everything from small saplings to thick brush.

Most landscapers find that starting with a standard bucket, grading bucket, and hydraulic thumb handles about 80% of their typical work. As your business grows or specializes, you can add attachments that address your specific needs.

I’ve watched customers transform their businesses by having the right attachments ready when opportunity knocks. One landscaper told me adding a tiltrotator to his Takeuchi excavator allowed him to take on precision grading jobs he previously had to turn down, opening up an entirely new revenue stream.

Conclusion

Compact excavators have truly transformed the way Wisconsin contractors tackle challenging job sites. These mighty machines bring heavyweight capabilities to tight spaces without compromising on performance or productivity. Whether you’re digging foundations, installing utility lines, or crafting intricate landscapes, these versatile workhorses deliver impressive results in a package that’s both transport-friendly and operator-friendly.

Throughout this guide, we’ve seen how today’s compact excavators offer remarkable features that boost both productivity and operator comfort. From zero-tail swing designs that let you work safely next to buildings to sophisticated hydraulic systems that provide fingertip precision, these machines are engineering marvels. The eco modes reduce fuel consumption while maintaining performance, telematics systems keep your fleet running at peak efficiency, and quick-coupler systems allow you to switch attachments in minutes rather than hours.

At Kelbe Brothers Equipment, we take pride in offering Wisconsin’s contractors access to the industry’s finest compact excavator brands. Our selection includes Hitachi excavators known for reliability, Link-Belt excavators celebrated for innovation, Takeuchi compact excavators respected for durability, and New Holland mini excavators praised for versatility. Our experienced team doesn’t just sell equipment—we help you find the perfect machine that aligns with your specific needs, whether you’re purchasing new, seeking a quality used option, or renting for a particular project.

As a fourth-generation, family-owned business with deep Wisconsin roots, we understand the unique challenges local contractors face in our climate and terrain. When you partner with us, you’re not just getting equipment—you’re gaining a support team committed to your success. Our rapid response promise, 24/7 emergency support, and hassle-free service ensure your projects stay on schedule, even when the unexpected happens.

Ready to add a compact excavator to your fleet? Or perhaps you’re just exploring your options? Either way, we invite you to connect with our team or visit any of our convenient locations in Milwaukee, Madison, Green Bay, Butler, or De Pere. We’re here to help you find the right solution that fits your business needs, project requirements, and budget constraints, with the friendly, no-pressure guidance you deserve.