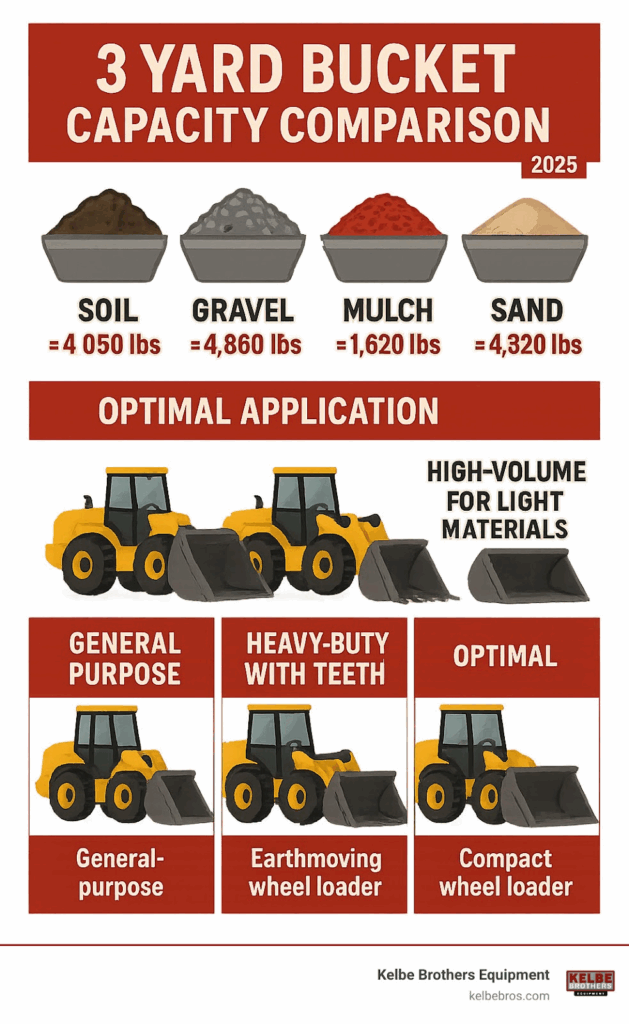

3-yard bucket attachments are high-capacity tools designed for wheel loaders that can handle substantial material loads efficiently. These buckets are engineered for large-scale commercial projects, heavy-duty landscaping, and material handling operations where productivity and speed matter most.

Key 3 Yard Bucket Specifications:

- Capacity: 3 cubic yards (approximately 81 cubic feet)

- Typical Weight: 1,300-2,000 pounds, depending on design

- Compatible Equipment: Hitachi Wheel Loaders, New Holland Wheel Loaders, Takeuchi Compact Wheel Loaders

- Primary Applications: Earth-moving, site preparation, debris removal, bulk material handling

- Design Types: General-purpose, heavy-duty with teeth, high-volume for light materials

For busy Wisconsin construction managers, choosing the right 3 yard bucket can make the difference between meeting project deadlines and costly delays. The wrong bucket type can lead to inefficient loading cycles, increased fuel consumption, and unnecessary equipment wear.

Whether you’re moving soil with a New Holland Wheel Loader or handling bulk materials with a Hitachi Wheel Loader, understanding the different bucket designs and their specific applications is crucial for maximizing your equipment’s performance and keeping projects on schedule.

As Jeffrey J. Miller, President of Kelbe Brothers Equipment, I’ve seen how the right 3-yard bucket selection can transform jobsite productivity for contractors across Wisconsin. With over 60 years of experience in construction equipment, our team understands that matching the right bucket to your specific application isn’t just about capacity—it’s about maximizing efficiency and minimizing downtime.

Understanding the Anatomy of a Loader Bucket

A 3 yard bucket is a precision-built attachment, not just a big steel scoop. Grade 50 steel, formed back wrappers, and rounded corners all work together to carry heavy payloads while protecting your Hitachi or New Holland loader from stress and fatigue.

Key Design Features

- Hardened, bolt-on cutting edge (0.6–0.7 in.) for fast, low-cost replacement.

- Round-nose profile that concentrates breakout force to penetrate compacted or frozen soil.

- Long floor & tall heel that let material settle, reducing spillage on the move.

- Reinforced side plates and wear guards that spread stress and fight abrasion.

Typical Specifications

- Capacity: 3 cu yd struck / ≈ 3.5 cu yd heaped.

- Weight: 1,300–2,000 lb, depending on duty class.

- Width: 96–120 in. (match to your loader’s lifting chart).

- ISO quick-coupler ready for rapid attachment swaps.

Need a replacement cutting edge today? Our parts counters in Milwaukee, Madison and Green Bay keep the common wear items in stock, so your loader is never down for long.

Matching Your 3 Yard Bucket to the Right Equipment

Getting the right 3 yard bucket matched to your wheel loader isn’t just about making sure it fits—it’s about making sure your equipment works safely and efficiently together. Think of it like pairing a powerful engine with the right transmission. You need both components working in harmony to get the job done right.

The most important factor is your machine’s lifting capacity. A fully loaded 3 yard bucket can easily weigh over 6,800 pounds when you factor in the bucket itself plus materials like gravel or soil. Your wheel loader needs to handle that weight without tipping forward or straining the hydraulic system.

Machine size and stability matter just as much as raw lifting power. A smaller wheel loader might technically lift a 3-yard bucket, but it could become dangerously unstable, especially on uneven ground or when reaching over spoil piles. The wheelbase and counterweight of your machine determine how safely you can operate with larger attachments.

Your hydraulic system also needs to match the bucket’s demands. Standard buckets require basic hydraulic flow, but if you’re looking at heavy-duty models with additional features, you’ll need higher flow rates and pressure. It’s like trying to run a high-performance engine on regular fuel—it just won’t perform as designed.

Wheel Loaders That Use a 3 Yard Bucket

Hitachi Wheel Loaders are built for serious material handling with 3-yard buckets. These machines shine on large-scale commercial projects where you’re moving substantial amounts of earth, gravel, or aggregate. The hydraulic systems on Hitachi loaders provide smooth, precise control that’s essential when you’re working with heavy loads in tight spaces.

New Holland Wheel Loaders bring excellent versatility to 3 yard bucket operations. These machines are particularly effective for earth-moving and site preparation work, offering great visibility and maneuverability. The load-sensing hydraulic systems optimize fuel efficiency while still delivering the power you need for heavy-duty material handling.

Takeuchi Compact Wheel Loaders represent the smaller end of machines that can handle 3 yard buckets effectively. While you might need to work with lighter materials or partial loads, these compact machines excel in tight spaces where larger loaders simply can’t operate. They’re perfect for urban construction projects and residential landscaping where maneuverability is key.

The type of material you’re handling makes a huge difference in equipment selection. A Takeuchi compact loader might handle 3 cubic yards of mulch all day long, but that same volume in gravel would overload the machine. Understanding these limitations helps you work safely and avoid costly equipment damage.

Ensuring a Secure and Safe Connection

Properly connecting your 3-yard bucket isn’t something to rush through. The forces generated during loading, lifting, and dumping operations are substantial, and a poorly secured attachment can lead to serious accidents.

Quick couplers have become the standard for good reason—they let you change buckets without leaving the cab, which saves time and reduces downtime. However, you must verify proper engagement and locking before starting work. A bucket that looks attached but isn’t properly locked can fail catastrophically.

Linkage pins and bearings take a beating during normal operations. These components experience tremendous stress and can fail without warning if not properly maintained. Make it a habit to visually inspect these parts daily, checking for excessive wear, proper lubrication, and secure fastening.

Hydraulic connections need to be properly sealed and secured to prevent leaks and ensure consistent operation. Hydraulic fluid loss reduces bucket performance and creates environmental hazards. Regular inspection of hydraulic lines, fittings, and cylinders helps catch problems before they become expensive repairs.

Following proper attachment procedures consistently is non-negotiable for safe operations. This means verifying coupler engagement, checking hydraulic connections, and testing bucket operation before beginning work. Your operators should be trained on these procedures and understand why daily equipment checks matter.

At Kelbe Brothers Equipment, our experienced technicians can guide you through proper attachment procedures and safety protocols. We’ve seen what happens when shortcuts are taken, and we’re here to help you avoid those problems. Learn more about our equipment service capabilities and how we help Wisconsin contractors maintain safe, efficient operations.

Top 3 Yard Loader Bucket Types Reviewed

One bucket style rarely covers every job. After six decades of field calls, Kelbe Brothers generally recommends three designs:

1. General-Purpose Bucket: the everyday solution

- Balanced weight and capacity for excavation, backfilling, and truck loading.

- Compatible with most Hitachi and New Holland wheel loaders we rent and sell.

- Moderate cutting-edge aggressiveness protects finished surfaces yet digs efficiently.

Perfect when your crew needs one attachment that can stay on the machine all day.

2. Heavy-Duty Bucket built for the ugly stuff

- Thicker shells, added gussets, and full-wrap wear plates survive rocks, frozen ground, and demolition debris.

- Replaceable teeth plus a curved, round nose focus breakout force.

- Heavier than a standard bucket, but far cheaper than repairing a twisted one.

Use it when the plan includes blasting through compacted sub-soil or loading shot rock.

3. High-Volume Bucket move more of the light material

- Extra-tall rear plate and extended floor create the space you need for snow, mulch, or wood chips.

- Lighter structure keeps finished weight within most loader charts.

- Curved back empties cleanly, speeding cycle times.

Pro tip: keep a high-volume bucket on a quick-coupler so you can swap back to a general-purpose design as soon as densities increase.

Maximizing Efficiency and Safety on the Jobsite

A good bucket only pays for itself when it is used correctly and safely. Start by laying out the work zone:

- Keep spoil piles at least 2 ft from trench edges as required by OSHA.

- Spot trucks on the loader’s left side, cab-to-cab, so the operator makes a short 25° swing.

- Plan to fill highway trucks in three to five passes; your 3-yard bucket and loader will stay productive without idling.

Proper Technique

- Dig top-down, shaving thin layers rather than fighting from the bottom.

- Avoid under-cutting banks; it destabilizes the face and creates extra clean-up.

- Keep the load low while travelling and steer smoothly—sudden moves spill material and burn fuel.

Daily Care

- Walk around the bucket, checking pins, coupler locks and hydraulic lines.

- Look for cracks at the corners and replace cutting edges before they reach the base lip.

- Clean sticky clay or asphalt from the shell to maintain full capacity.

Need a different attachment for tomorrow’s task? Our rental equipment options let you swap tools without slowing the schedule.

Frequently Asked Questions about 3 Yard Buckets

What types of projects are ideal for a 3-yard bucket?

A 3-yard bucket shines on projects where moving large volumes of material quickly makes the difference between profit and loss. After four generations in Wisconsin’s construction industry, we’ve seen these buckets transform productivity on everything from massive commercial developments to residential landscaping projects.

Large-scale commercial projects are where 3-yard buckets really prove their worth. When you’re preparing a site for a new shopping center or industrial facility, the ability to move substantial quantities of material with each pass can cut project timelines significantly. These buckets work beautifully with Hitachi wheel loaders and New Holland wheel loaders to handle the bulk material movement that commercial projects demand.

Residential landscaping has become another sweet spot for 3-yard buckets. When you’re spreading topsoil across a large residential development or moving mulch for extensive landscaping, the increased capacity means fewer trips and happier customers. The efficiency gains are particularly noticeable when working with light materials like mulch or wood chips.

Bulk material handling operations benefit tremendously from the larger capacity. Loading trucks with aggregate, soil, or recycled materials becomes much more efficient when you can move 3 cubic yards per cycle instead of smaller amounts. Your fuel costs drop, your equipment experiences less wear, and your operators can complete more work in a day.

Earth-moving for site development, road construction, and utility installation represents another ideal application. When you’re moving hundreds of cubic yards of soil, the difference between a smaller bucket and a 3-yard bucket can mean the difference between finishing on schedule or working overtime.

How does a bucket’s design affect its performance?

The design details that might seem minor actually make huge differences in how well your 3-yard bucket performs day after day. We’ve watched contractors struggle with poorly designed buckets, and we’ve seen others boost their productivity dramatically with the right design features.

Round nose design on heavy-duty buckets concentrates all that digging force into a smaller contact area. Think of it like the difference between pushing with your finger versus your whole hand – the round nose creates much higher pressure at the contact point. This design excels at breaking through compacted soil, frozen ground, or materials with rocks and debris mixed in.

The longer floor and taller back on light material buckets might look like simple changes, but they transform how the bucket handles materials like mulch or snow. The longer floor gives material more space to settle, while the taller back prevents spillage during transport. We’ve seen operators increase their payload by 20% or more just by switching to a properly designed bucket for their material type.

Curved back design serves multiple purposes that aren’t obvious at first glance. The curve guides material into the bucket during loading, improving fill efficiency significantly. It also creates a natural flow pattern that prevents material from bridging across the bucket opening – particularly important with light, fluffy materials that might otherwise create air pockets.

Hardened steel edges and teeth provide the durability and digging power that separate professional-grade buckets from cheaper alternatives. These components can be replaced when worn, making them a smart long-term investment. The hardness and geometry directly affect how well the bucket penetrates different materials, from soft topsoil to rocky subsoil.

What should I look for when inspecting a used bucket?

When you’re considering used construction equipment for sale, a thorough bucket inspection can save you thousands in unexpected repairs or replacement costs. We’ve helped countless contractors evaluate used buckets, and certain warning signs consistently predict future problems.

Cracks in welds represent the most serious concern during any used bucket inspection. These typically develop at high-stress areas like mounting points, corners, and transitions between different steel thicknesses. Small cracks might be repairable by a skilled welder, but extensive cracking usually means the bucket is approaching the end of its useful life.

Cutting edge and tooth wear should be evaluated not just for remaining material, but for what the wear pattern tells you about how the bucket was used. Cutting edges worn down to the bucket lip indicate the previous owner operated beyond recommended replacement intervals, potentially causing damage to the bucket structure itself.

Structural dents and warping can reveal a bucket’s history of overloading or impact damage. Minor dents rarely affect performance, but significant warping affects material flow and may indicate underlying structural damage that’s not immediately visible.

Mounting plate condition is absolutely crucial for safe operation. Damaged mounting plates or coupler interfaces can prevent proper attachment to your machine, creating serious safety hazards. Excessive wear in the mounting area often indicates improper attachment procedures or operation with an incompatible machine.

The interior wear patterns provide valuable insight into the bucket’s maintenance history and usage patterns. Excessive wear in specific areas might indicate improper operating techniques or use with inappropriate materials. Uniform wear patterns generally suggest proper use and regular maintenance – exactly what you want to see in used equipment.

Conclusion

Choosing the right 3-yard bucket is crucial for maximizing the performance of your wheel loader and ensuring job site efficiency. By matching the bucket type—whether general purpose, heavy-duty, or high-volume—to your specific application and equipment, you can move more material in less time while keeping your projects on track and profitable.

The investment in the right bucket pays real dividends through improved productivity, reduced fuel consumption, and lower equipment wear. When you understand the differences between bucket types and their optimal applications, you make informed decisions that directly improve your bottom line—and that’s something every contractor can appreciate.

For contractors here in Wisconsin, the choice of bucket becomes even more critical given our unique challenges. Our harsh winters and diverse soil conditions require equipment that can handle everything from frozen ground in January to light snow removal operations. This makes bucket selection particularly important for year-round operations where versatility and reliability matter most.

Equipment compatibility remains the foundation of smart bucket selection. Whether you’re running Hitachi Wheel Loaders, New Holland Wheel Loaders, or Takeuchi Compact Wheel Loaders, each machine has specific capabilities and limitations that must be considered when selecting a 3-yard bucket. Proper matching ensures safe operation and optimal performance—no surprises, no downtime, no headaches.

As a fourth-generation, family-owned company, Kelbe Brothers Equipment understands the importance of having the right tools for Wisconsin’s demanding construction environment. We’ve been helping contractors steer these decisions for decades, and our experienced staff knows how to cut through the complexity of bucket selection to ensure you get the maximum return on your equipment investment.

Whether you’re handling bulk materials in Milwaukee, preparing sites in Madison, or managing landscaping projects in Green Bay, the right 3-yard bucket can transform your operational efficiency. Our comprehensive inventory and expert knowledge ensure you have access to the best equipment for your specific needs—because we know that in this business, having the right tool for the job isn’t just convenient, it’s essential.

For contractors looking to optimize their material handling capabilities, we offer expert guidance and a wide selection of attachments to ensure you have the right tools for the job. Contact us to find the perfect bucket parts for your Hitachi, New Holland, or Takeuchi loader today.