A 1-yard loader bucket is a specialized attachment designed to hold exactly one cubic yard of material (the cubic yard is a standard measure equal to 27 ft³), making it the perfect size for mid-range construction and landscaping tasks. These buckets are engineered for efficient material handling, whether you’re loading trucks, moving gravel, or grading surfaces on Wisconsin job sites.

Key 1-Yard Loader Bucket Specifications:

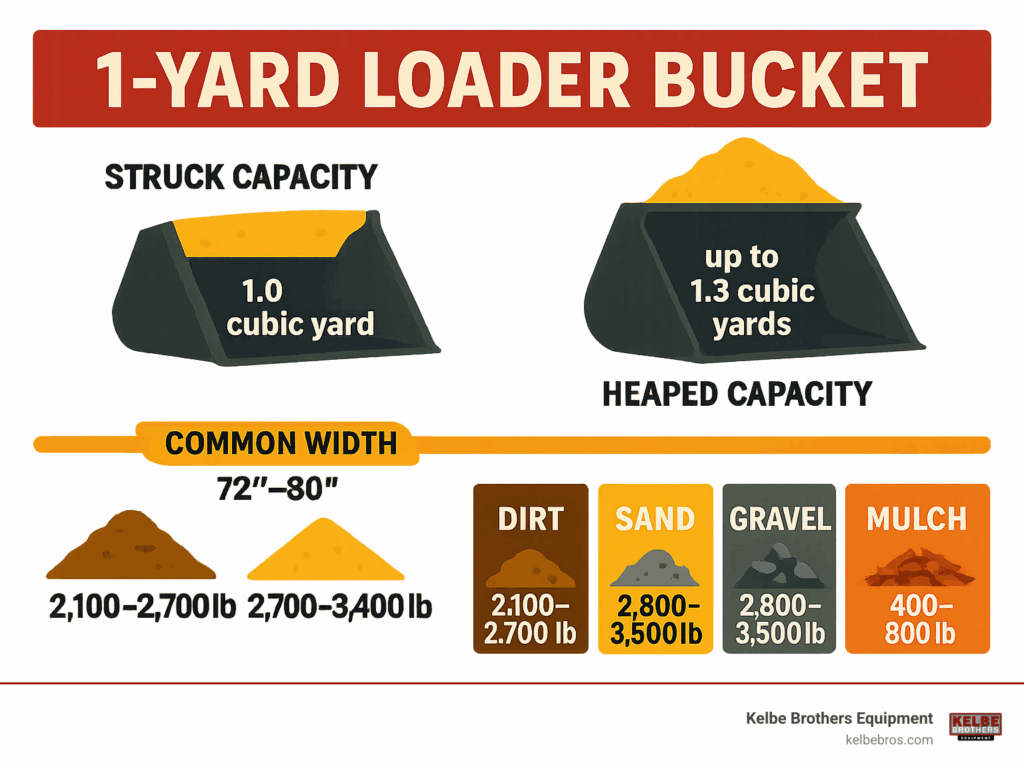

- Capacity: 1.0 cubic yard (heaped capacity may be higher)

- Width: Typically 72-80 inches

- Weight: 600-800 pounds, depending on construction

- Compatible Equipment: Hitachi wheel loaders, New Holland compact wheel loaders, Takeuchi compact track loaders, New Holland skid steer loaders

Common Applications:

- Loading trucks with dirt, sand, and gravel

- Moving bulk materials like mulch and wood chips

- Site cleanup and debris removal

- Snow removal operations

- General construction and landscaping tasks

The versatility of a 1-yard capacity makes it ideal for contractors who need to balance productivity with machine stability. Whether you’re handling dense materials like shot rock or lighter substances like agricultural feed, the right 1-yard bucket design can significantly improve your operational efficiency.

As Jeffrey J. Miller, President of Kelbe Brothers Equipment, I’ve helped Wisconsin contractors select the perfect 1-yard loader bucket for their specific applications over many years in the construction equipment industry. My experience has shown that choosing the right bucket design can make the difference between a profitable job and costly delays.

A Bucket for Every Task: Common Designs and Types

Not all 1-yard loader buckets are created equal. Different designs excel at specific tasks, and understanding these variations helps you choose the right attachment for your operation. From our years of experience serving Wisconsin contractors, we’ve seen how the right bucket choice can dramatically improve job site efficiency.

General Purpose (GP) Buckets

When contractors ask me about the most versatile bucket option, I always point them toward general-purpose buckets. These workhorses handle the materials you encounter most often on Wisconsin job sites – dirt, sand, gravel, and construction debris. They’re designed for materials weighing between 1,800 and 3,000 pounds per cubic yard, which covers most construction applications.

You’ll find two main varieties: standard duty versions for lighter work and heavy duty models with thicker steel and extra reinforcement for demanding applications. The heavy-duty buckets feature reinforced cutting edges and side wear protection that really pays off when you’re working with abrasive materials day after day.

Most of our wheel loaders for sale come equipped with general-purpose buckets as standard equipment. This gives contractors immediate versatility for multiple job site tasks without needing specialized attachments right away. The balanced design offers excellent material retention while maintaining good breakout force for digging applications.

High-Volume / Light Material Buckets

Here’s where things get interesting for landscaping and agricultural operations. High-volume buckets are specifically engineered for low-density materials weighing less than 1,800 pounds per cubic yard. Think snow, mulch, wood chips, and agricultural feed materials where volume matters more than weight.

The secret is in the design. These buckets feature taller back heights for superior material retention and longer floor lengths to prevent spillage. The formed back wrapper uses optimized angles, while rounded corners improve loading efficiency and reduce material packing during operation.

A typical high-volume bucket measures about 80 inches wide and weighs around 700 pounds, with close to 1 cubic yard capacity. The increased cubic capacity allows operators to move more material per cycle without exceeding their Hitachi wheel loader’s weight limitations.

Learn more about Light Material Buckets

4-in-1 (Multi-Purpose) Buckets

If versatility is your priority, the 4-in-1 bucket is hard to beat. These clever attachments combine four functions in one: dozing, clamping, back-dragging, and loading. The hydraulically operated clam shells can grasp materials securely or perform precise grading operations.

The clamping action is what sets these buckets apart. With typical clamp forces around 3,000 pound-feet, they can securely grasp loose materials that would spill from a standard bucket. The serrated edges help maintain grip on challenging materials during transport.

What I love about 4-in-1 buckets is how they reduce attachment changes throughout the day. You can load trucks, grade surfaces, and clamp materials without switching attachments. This multi-functionality improves job site efficiency, especially on smaller projects where one machine needs to handle multiple tasks.

Specialized Nursery Buckets

For landscaping and nursery operations, narrow-width design buckets solve a specific problem. These specialized attachments fit perfectly between the sides of pickup truck beds, eliminating spillage during loading operations. No more sweeping up expensive mulch from the ground!

The precise measurement capability is another advantage. With an exact 1.00 cubic yard capacity, you can bill customers accurately without having to meter bulk materials from larger buckets. This precision matters when you’re loading free-flowing materials like mulch, gravel, and topsoil directly into customer vehicles.

Typical nursery buckets measure 54-60 inches wide (much narrower than standard buckets) and weigh between 710-785 pounds, depending on the coupler type. They work well with New Holland compact wheel loaders, Takeuchi compact wheel loaders, and other mid-size machines commonly used in landscaping operations.

Built to Last: Key Features of a High-Performance 1 Yard Loader Bucket

When you’re investing in a 1-yard loader bucket, you want it to work hard for years without breaking down. After decades of helping Wisconsin contractors choose the right attachments, I’ve learned that the difference between a bucket that lasts one season and one that serves you for years comes down to smart design and quality construction.

The harsh reality is that buckets take a beating. They scrape concrete, dig through rocky soil, and handle tons of abrasive materials every day. That’s why understanding what makes a bucket truly durable can save you thousands in replacement costs and lost productivity.

Critical Design Elements

The cutting edge takes the hardest hits on any job site. Think of it as your bucket’s front-line soldier – it needs to be tough enough to penetrate packed dirt and sharp enough to slice through root systems. Quality buckets feature replaceable bolt-on cutting edges made from high-strength steel, typically running 0.6 to 0.75 inches thick.

Here’s what many contractors don’t realize: the cutting edge isn’t just about thickness. The steel quality matters enormously. High-strength steel maintains its sharp edge longer and resists chipping better than cheaper alternatives. When that edge finally wears down, you can simply unbolt it and install a new one instead of replacing the entire bucket.

Wear plates act like armor for your bucket’s most vulnerable spots. Side wear bars, usually 3/8 inch thick, protect the bucket walls from constant material flow. Bottom wear bars, often 4-1/2 inches wide, shield the bucket floor from rocks and debris that would otherwise wear through the base metal.

The bucket shell forms your attachment’s backbone. Light material buckets might use 3/16 inch steel since they’re not handling rocks and gravel. Heavy-duty versions step up to 3/8 inch or thicker steel, sometimes with specialized wear plates for extreme conditions.

Reinforcement ribs distribute stress throughout the bucket structure. Without proper reinforcement, stress concentrates at weak points and creates cracks that can sideline your equipment. Strategic rib placement, combined with quality welding, ensures your bucket handles heavy loads without failing.

Spill guards might seem like a small detail, but they prevent material loss during transport. Proper rollback and dump angles optimize how efficiently you can load and unload materials. These geometric considerations directly impact your productivity on every job.

Materials and Construction

High-strength steel construction separates professional-grade buckets from cheaper alternatives. Hardened steel edges provide excellent penetration and extended wear life. Base edge thickness typically ranges from 0.7 inches for standard applications up to over 1 inch for severe rock work.

Quality welding makes or breaks bucket durability. Certified welders and proper joint preparation prevent premature failures that could leave you stranded mid-job. Some manufacturers grind welds smooth to reduce stress concentrations – a small detail that extends service life significantly.

Side wear bars and bottom wear bars protect against abrasion while remaining replaceable. This smart design lets you maintain your bucket’s performance without major repairs. Universal mount plates ensure compatibility with various coupler systems, increasing your attachment’s versatility across different machines.

When wear components finally need replacement, having access to quality parts keeps your bucket working like new. Find durable replacement parts to maintain your bucket’s performance and extend its service life.

Typical Specifications for a 1-Yard Loader Bucket

Understanding how specifications vary between bucket types helps you choose the right attachment for your specific needs:

| Specification | General Purpose | High Volume | Heavy Duty |

| Width | 72-80 inches | 80+ inches | 72-78 inches |

| Weight | 600-700 lbs | 650-750 lbs | 700-850 lbs |

| Cutting Edge | 0.6-0.7 inches | 0.6 inches | 0.75+ inches |

| Body Material | 1/4 inch steel | 3/16 inch steel | 3/8+ inch steel |

| Side Wear Bars | 3/8 inch | 1/4 inch | 1/2 inch |

| Capacity (struck) | 1.0 cubic yard | 1.0 cubic yard | 1.0 cubic yard |

| Capacity (heaped) | 1.3 cubic yards | 1.5+ cubic yards | 1.2 cubic yards |

Notice how heavy-duty buckets sacrifice some heaped capacity for increased durability. That thicker steel and reinforced construction mean slightly less volume but dramatically longer service life in tough conditions.

High-volume buckets maximize capacity for lighter materials, while general-purpose buckets balance durability with versatility. Each design optimizes different performance aspects while maintaining that core 1-yard capacity that makes these attachments so practical for mid-size operations.

The Perfect Match: Equipment Compatibility

Getting the right 1-yard loader bucket on the right machine makes all the difference between a smooth workday and constant headaches. After decades of helping Wisconsin contractors match equipment, I’ve learned that compatibility goes far beyond whether the bucket physically bolts on. You need to consider machine size, lift capacity, hydraulic requirements, and how everything works together on your specific job sites.

Compatible Loader Types

Hitachi wheel loaders are excellent partners for 1-yard buckets, especially when you need serious lifting power and stability. These machines deliver strong breakout force through robust hydraulic systems, making them perfect for dense materials like gravel and construction debris. The articulated design gives you great maneuverability while keeping excellent traction on uneven surfaces.

Takeuchi compact track loaders really shine with 1-yard loader buckets because of their incredible stability and low ground pressure. The track design means you can work on soft ground without sinking, while the compact size lets you operate in tight spaces where wheel loaders might struggle. Models in the TL series offer that sweet spot of power and agility that makes bucket work efficient.

New Holland compact wheel loaders bring mobility and versatility to bucket operations. Their quick-attach systems make switching between buckets fast and easy, which keeps your crew productive throughout the day. The compact design is perfect for urban construction sites where space is tight, but you still need serious lifting capability.

The New Holland Skid Steer Loaders: 200 Series provide exceptional maneuverability with their zero-turn radius, giving you precise control when positioning your bucket. The lift-arm design offers excellent visibility to the cutting edge, so you can see exactly what you’re doing. With various models available, you can find the right capacity match for your specific needs.

Takeuchi compact wheel loaders offer the best of both worlds – the mobility of wheels with the stability you need for bucket work. Their four-wheel drive systems provide excellent traction, while the compact wheelbase lets you work in confined areas. The comfortable operator environment reduces fatigue during those long days moving material.

Matching Your Machine for Optimal Performance

Operating capacity is where the rubber meets the road in equipment matching. Your 1-yard loader bucket might weigh 600-800 pounds empty, but add a full yard of dense material and you’re looking at 2,500-3,800 pounds total. The golden rule is keeping this combined weight under 50% of your machine’s tipping load for safe operation.

Quick-attach plates and universal mount systems make life much easier for contractors with mixed fleets. Standard mounting patterns mean the same bucket can work with multiple machines, giving you flexibility and reducing the number of attachments you need to stock.

Hydraulic requirements vary significantly between bucket types. Simple buckets only need basic lift and tilt functions, but 4-in-1 buckets require additional hydraulic circuits for clamping operations. Make sure your machine provides adequate hydraulic flow and pressure for your chosen bucket design.

View our new and used equipment to find the perfect loader for your bucket applications. Our inventory includes New Holland compact wheel loaders, Takeuchi compact wheel loaders, and other compatible machines designed for optimal bucket performance. As your local New Holland dealer, Takeuchi dealer, and Hitachi excavator dealer, we can help you find the right combination of machine and attachment for your specific needs.

Boosting Job Site Productivity and Efficiency

The right 1-yard loader bucket dramatically improves job site productivity through faster material handling, reduced cycle times, and improved versatility. Our Wisconsin contractors consistently report significant efficiency gains when using properly matched buckets.

Faster Loading and Moving

Optimal bucket shape maximizes material retention while minimizing spillage during transport. The long floor length and tall back height of high-volume buckets provide excellent material retention; a typical high-volume design measures about 38.5 inches long and 29 inches tall.

Efficient breakout force comes from proper bucket geometry and sharp cutting edges. The rollback angle affects digging performance, while the dump angle influences unloading efficiency. Quality buckets balance these factors for optimal performance across various materials.

Reduced spillage saves time and materials while keeping job sites cleaner. Features like rounded corners and formed back wrappers improve loading efficiency by reducing material packing. The serrated edges found on 4-in-1 buckets firmly grasp materials for secure movement.

Improved cycle times result from faster loading, reduced spillage, and efficient unloading. A well-built 72″ × 38″ × 27″ bucket, for example, optimizes material flow while maintaining structural strength. These design considerations directly impact productivity and profitability.

Versatility with the Right Attachment

One machine equipped with the right bucket can handle multiple tasks, reducing the need for additional equipment. A 4-in-1 bucket allows dozing, clamping, back-dragging, and loading operations with a single attachment. This versatility reduces equipment changes and simplifies job site logistics.

Quick attachment changes maximize machine utilization throughout the workday. Modern quick-attach systems built to common global patterns allow bucket changes in minutes rather than hours, keeping projects moving efficiently.

Reducing the need for other equipment simplifies operations. Instead of requiring separate dozers, grapples, and buckets, a single machine with a 4-in-1 bucket can handle multiple functions. This consolidation reduces fuel consumption, maintenance requirements, and operator training needs.

Check our rental equipment options to experience the productivity benefits of quality buckets before making a purchase decision. Our construction equipment rentals include properly matched bucket and loader combinations for optimal performance.

Frequently Asked Questions about 1-Yard Loader Buckets

How do I know if a 1-yard bucket is the right size for my loader?

The secret to safe bucket operation lies in understanding your machine’s capabilities. Start by checking your loader’s manual for the rated operating capacity (ROC) and tipping load specifications. Here’s the golden rule: the combined weight of your bucket and material should never exceed 50% of the tipping load.

Let’s say your Hitachi wheel loader has a 4,000-pound tipping load. That means your maximum safe operating weight is 2,000 pounds. A typical 1-yard loader bucket weighs 600-800 pounds, leaving you with 1,200-1,400 pounds for material capacity.

Material density makes all the difference in your calculations. Dense materials like wet sand or gravel pack a hefty 2,500-3,000 pounds per cubic yard, while lighter materials like mulch or snow weigh only 800-1,200 pounds per cubic yard. This is why matching your bucket type to your typical materials is so important.

From our experience with Wisconsin contractors, smaller machines work beautifully with high-volume buckets for light materials, while larger machines can handle general-purpose buckets loaded with dense materials. The key is finding that sweet spot where productivity meets safety.

What is the difference between a general-purpose and a light material bucket?

Think of general-purpose buckets as the heavy lifters of the bucket world. They’re built tough with thicker steel construction and reinforced cutting edges to handle dense materials like dirt, sand, and gravel weighing 1,800-3,000 pounds per cubic yard. These buckets can tackle whatever you throw at them within their capacity limits.

Light material buckets take a completely different approach. They maximize cubic capacity but are designed specifically for low-density materials weighing less than 1,800 pounds per cubic yard. These buckets excel at moving snow, grain, fertilizer, mulch, wood chips, and livestock feed.

The critical difference isn’t just size – it’s about material density limitations. A general-purpose bucket is like a versatile tool that can handle any material within its capacity. A light material bucket is more specialized, designed to move the maximum volume of lighter materials without overloading your machine.

Using the wrong bucket type can lead to stability issues or machine damage. We’ve seen contractors try to move heavy gravel with light material buckets, and it never ends well. Match your bucket to your materials, and you’ll work safer and more efficiently.

How can I extend the life of my loader bucket?

Smart operating habits make the biggest difference in bucket longevity. Never scrape in reverse – this single mistake causes more cutting-edge damage than almost anything else. The cutting edge is engineered to work in one direction, and reverse scraping can cause premature wear or even catastrophic damage.

Quality buckets feature bolt-on cutting edges and wear plates that can be replaced when worn. This design philosophy means you’re replacing affordable wear components instead of entire buckets. Regular replacement of these parts is far more cost-effective than bucket replacement.

Proper storage extends bucket life significantly. Keep your bucket off the ground when not in use to prevent corrosion. Perform regular visual inspections for cracks, excessive wear, or loose bolts. Catching small problems early prevents them from becoming expensive failures.

Your bucket works hard, so give it the attention it deserves. Address issues promptly, follow proper operating procedures, and invest in quality replacement parts when needed.

Schedule a service check-up to have our experienced technicians inspect your bucket and recommend maintenance or replacement parts.

Conclusion: Finding the Right Bucket for Your Wisconsin Operation

Selecting the perfect 1-yard loader bucket comes down to understanding your specific needs and matching them with the right design. After decades of helping Wisconsin contractors make these decisions, I’ve learned that the best bucket choice depends on three key factors: your typical materials, your machine’s capabilities, and your job site requirements.

The difference between a general-purpose bucket handling construction debris and a high-volume bucket moving mulch isn’t just about capacity—it’s about maximizing your machine’s potential while staying within safe operating limits. Dense materials like gravel demand the robust construction of a general-purpose design, while light materials like wood chips benefit from the increased volume of specialized buckets.

Quality construction matters more than you might think. Those hardened cutting edges, replaceable wear plates, and strategic reinforcement ribs aren’t just nice features—they’re what keep your bucket working when others fail. We’ve seen contractors save thousands in replacement costs simply by choosing buckets with proper wear protection and bolt-on components.

At Kelbe Brothers Equipment, our fourth-generation family business has built its reputation on understanding exactly what Wisconsin contractors need. Our experienced team doesn’t just sell equipment—we help you choose the right tools for your specific applications. Whether you’re running Hitachi wheel loaders, Takeuchi compact track loaders, or New Holland compact wheel loaders, we ensure your bucket matches your machine perfectly.

The investment in a quality 1-yard loader bucket pays for itself through improved efficiency and reduced downtime. We’ve watched contractors increase their productivity by 30% or more simply by switching to the right bucket design. From snow removal operations in northern Wisconsin to landscaping projects in Madison, the right bucket makes every job smoother and more profitable.

As your trusted Hitachi excavator dealer, Takeuchi dealer, New Holland dealer, and Link-Belt dealer, we provide complete support from selection through service. Our locations throughout Wisconsin mean you’re never far from expert advice, quality parts, or emergency support when you need it most.

Ready to find the perfect bucket for your operation? Contact us to find the perfect parts for your loader and find out why Wisconsin contractors have trusted Kelbe Brothers Equipment for generations. We’re here to help you work smarter, not harder.