When you buy small digger equipment, you’re investing in versatile machines that can transform how you tackle construction and landscaping projects. Mini excavators and compact loaders typically weigh between 1-6 tons and offer exceptional maneuverability in tight spaces where larger equipment simply won’t fit.

Top small digger options for Wisconsin contractors:

- Takeuchi Compact Excavators – Superior hydraulics and zero swing models for confined spaces

- New Holland Mini Excavators – Reliable performance with easy maintenance access

- Hitachi Wheel Loaders – Fuel-efficient with advanced operator comfort features

- Link-Belt Excavators – Robust construction for demanding conditions

These compact machines excel at trenching, material handling, landscaping, and utility work. With operating weights ranging from 0.7 to 8.5 tons and digging depths typically between 1.5 to 4 meters, they deliver the power you need without the bulk of full-size equipment.

The versatility comes from their extensive attachment options – from standard buckets and hydraulic thumbs to augers, breakers, and specialized tools. Whether you’re digging foundations, clearing land, or handling materials, the right small digger can significantly boost your productivity while accessing areas that would otherwise require manual labor.

As Jeffrey J. Miller, President of Kelbe Brothers Equipment, I’ve helped Wisconsin contractors buy small digger equipment for over 60 years of combined family business experience. My focus is on ensuring you get the right compact machine with the support needed to keep your projects moving forward efficiently.

Why Own a Small Digger? The Benefits for Your Projects

Picture this: it’s 7 AM on a Tuesday, and you’ve got three different projects calling for equipment. When you buy small digger equipment, you’re not scrambling to coordinate rental schedules or waiting for delivery trucks. Your machine is right there, ready to tackle whatever the day brings.

The productivity boost is immediate and noticeable. Takeuchi excavators and New Holland mini excavators deliver faster cycle times than their larger counterparts, especially in confined spaces. You’re moving more material in less time, which means wrapping up jobs ahead of schedule and moving on to the next paying project.

Precision control is where these machines truly earn their keep. Whether you’re threading a Takeuchi compact excavator through a residential backyard or using New Holland compact track loaders for delicate landscaping work, the smooth hydraulic systems give you the finesse needed for detailed operations. No more hand-digging around utility lines or struggling with oversized equipment in tight spots.

The attachment versatility transforms a single machine into your entire fleet. One morning, your New Holland compact wheel loader is moving gravel, and by afternoon, it’s equipped with an auger for fence post installation. This flexibility means fewer machines to maintain, insure, and transport between job sites.

Maneuverability opens up job opportunities you might have passed on before. These machines slip through standard gates and work in spaces where larger equipment would damage landscaping or simply won’t fit. That residential pool excavation or backyard addition project becomes profitable instead of problematic.

Reduced labor needs directly impact your bottom line. Tasks that once required a crew with shovels now need just one skilled operator. Your workers can focus on higher-value activities while the machine handles the heavy lifting and digging.

The operator comfort in modern machines like Hitachi wheel loaders and Link-Belt excavators keeps your team productive throughout long days. Ergonomic controls, climate-controlled cabs, and smooth operation reduce fatigue and increase job satisfaction.

Essential Features to Consider When You Buy a Small Digger

When you’re ready to buy small digger equipment, understanding the key specifications will help you choose the machine that perfectly fits your project needs. Think of it like buying a truck – you need to match the capabilities to your intended use.

Operating weight is your starting point and directly affects what your machine can accomplish. Lighter units around 1-3 tons give you incredible maneuverability for landscaping and utility work, while heavier models in the 4-6 ton range provide the stability and power needed for more demanding construction tasks. Operating weight also determines your transport requirements – will you need a special trailer or CDL license?

The digging envelope – that’s your reach, depth, and lift capacity – defines your working area. Most small excavators offer digging depths between 1.5-4 meters, with maximum digging heights reaching 2.6 meters. The digging radius typically ranges from 2.8 to 3.5 meters, which means you can cover substantial ground without constantly repositioning your machine.

Engine power makes all the difference when you’re pushing through tough soil or running multiple attachments. Small excavators typically feature 18-25 horsepower engines for light applications, while larger models may have 40-50 horsepower for heavier work. More power means you can tackle demanding jobs without the machine struggling or slowing down.

Your hydraulic system performance is what gives you that smooth, precise control that makes operating these machines feel almost effortless. Look for systems with adequate main pump displacement and operating pressure around 16 MPa – this provides sufficient power for most attachments while maintaining the precise control you need for detailed work.

The undercarriage choice between tracks and wheels significantly impacts where and how you can work. Rubber tracks provide excellent traction and stability on soft or uneven ground, making them ideal for landscaping and utility work. Wheeled units offer faster transport speeds on hard surfaces but may struggle in muddy conditions. Some models feature retractable undercarriages that extend for increased stability during heavy lifting operations.

Cab configuration affects both operator comfort and safety throughout long work days. Open canopy designs with ROPS (Roll-Over Protective Structure) provide adequate protection for many applications and offer excellent visibility. Enclosed cabs with FOPS (Falling Object Protective Structure) add climate control and improved safety in challenging environments – your operators will definitely appreciate this during Wisconsin winters.

Don’t overlook auxiliary hydraulics and quick couplers – these features dramatically expand your machine’s versatility. Quick couplers allow you to switch between attachments in minutes rather than hours, while auxiliary hydraulics power specialized tools like hydraulic breakers and augers.

Ergonomic operator controls might seem like a small detail, but they make a huge difference in productivity and operator fatigue. Look for intuitive joystick patterns and well-placed controls that allow smooth, natural operation.

For ongoing support and maintenance needs, our equipment service team ensures your investment continues performing at peak efficiency throughout its operational life.

A Closer Look at Top-Performing Mini Earth Movers

When you’re ready to buy small digger equipment, understanding the standout features of leading manufacturers helps you make the right choice. Each brand brings unique strengths to the table, and knowing what sets them apart can save you time and money down the road.

Takeuchi Compact and Zero Swing Excavators

Takeuchi has earned a reputation for building some of the most reliable compact excavators in the industry. Their zero swing excavators are particularly impressive – these machines rotate completely within their track width, which means you never have to worry about the back end swinging into obstacles.

This zero swing design is a game-changer for tight job sites. Picture working between two houses with just enough room for your machine – with a traditional excavator, you’d constantly worry about hitting something when you rotate. Takeuchi’s zero swing models eliminate that concern entirely.

The hydraulic systems in these machines deliver incredibly smooth operation. Operators often tell us they appreciate how responsive the controls feel, especially when doing precision work like trenching around utilities or placing materials exactly where they need to go.

Durability is where Takeuchi really shines. These machines are built to handle tough conditions day after day. The undercarriage components – tracks, rollers, and drive systems – are engineered for the long haul, even when you’re working in rocky or abrasive conditions.

Whether you’re a landscaping contractor working around existing plantings or a utility contractor digging near sensitive infrastructure, Takeuchi compact excavators give you the precision and reliability you need. Check out our new equipment selection to see the latest Takeuchi models available.

Hitachi Wheel Loaders

Hitachi wheel loaders stand out for their impressive fuel efficiency and smart technology features. These machines automatically adjust engine power based on what you’re doing, which means you’re not burning extra fuel when you don’t need the power.

The operator interface includes digital displays that show you real-time performance data and maintenance alerts. It’s like having a co-pilot that helps you get the most out of your machine while catching potential issues before they become expensive problems.

Comfort is a big focus in Hitachi wheel loader design. The cabs are spacious with excellent visibility in all directions, and the climate control systems keep you comfortable whether it’s sweltering summer heat or bitter Wisconsin winter cold. The smooth ride quality, thanks to advanced suspension systems, means less fatigue during those long work days.

These machines are built for reliability. Components are designed for extended service intervals, which translates to lower maintenance costs and less downtime. The robust construction ensures consistent performance even when conditions get challenging.

Environmental considerations haven’t been overlooked either. Advanced emission control systems meet current standards while maintaining the performance you need to get work done efficiently.

New Holland Mini Excavators and Loaders

New Holland mini excavators and compact loaders are designed with versatility and serviceability in mind. These machines make maintenance easy with service points positioned where you can actually reach them during daily inspections and routine maintenance.

The New Holland 200 Series skid steer loaders and compact track loaders pack impressive power into compact packages. The vertical lift design increases both load capacity and reach, which is particularly helpful when you’re loading high-sided trucks or clearing dumpster sides.

New Holland compact wheel loaders feature articulated steering that gives you excellent maneuverability in tight spaces while maintaining stability during material handling. The balanced design ensures optimal weight distribution for maximum traction and stability.

One standout feature in New Holland mini excavators is the swing boom technology. The boom can pivot left and right, expanding your working area without having to reposition the entire machine. This is incredibly valuable when you’re working alongside buildings or in other confined spaces.

The comprehensive attachment ecosystem means you can equip your machine for virtually any task. From standard buckets and hydraulic thumbs to augers, breakers, and specialized material handling attachments, New Holland provides solutions for diverse operational needs.

Link-Belt Excavators

Link-Belt excavators have built their reputation on robust construction and reliable performance in demanding conditions. These machines feature fuel-efficient engines that deliver optimal power while keeping operating costs manageable – something every contractor appreciates.

The precision hydraulic controls enable operators to perform delicate operations with confidence. The smooth joystick response and precise flow control allow for accurate material placement and careful excavation work around utilities or existing structures.

Durability is engineered into every component. The undercarriage systems are designed for extended service life, even in abrasive conditions that would wear out lesser machines. The reinforced boom and arm structures handle heavy loads and resist wear from challenging applications.

Advanced diagnostic systems provide real-time monitoring of critical systems, alerting operators to potential issues before they become costly problems. This proactive approach reduces downtime and extends equipment life – exactly what you want when you buy small digger equipment for your business.

The operator environment prioritizes comfort and productivity. Spacious seating, intuitive controls, and excellent visibility combine with effective climate control to maintain comfortable working conditions regardless of external weather.

For quality pre-owned options, browse our used equipment inventory to find well-maintained units that deliver reliable performance and exceptional value.

Navigating Your Purchase: New vs. Used and Support

Key Factors When You Buy a Small Digger that is Pre-Owned

The hour meter tells the story of how hard a machine has worked. When you buy small digger equipment that’s pre-owned, machines with 4,000-5,000 hours represent what we consider moderate usage. Think of it like buying a car with reasonable mileage – you’re getting value without excessive wear.

Maintenance history is like a machine’s medical records. Well-maintained Takeuchi excavators or New Holland mini excavators with complete service records show you’re dealing with responsible previous owners. Always ask for maintenance logs, service receipts, and records of any major component replacements.

Your eyes are your best inspection tools. Walk around the used construction equipment for sale and look for obvious problems. Check the undercarriage components – tracks, rollers, and sprockets shouldn’t show excessive wear. Examine hydraulic cylinders for leaks or scoring. Look at the boom and arm for cracks or signs of previous repairs.

The hydraulic system deserves special attention during your evaluation. Test every function, including boom, arm, bucket, and swing operations. Listen for unusual noises or watch for jerky movements that might signal expensive hydraulic problems down the road.

Undercarriage wear can be a budget killer if you’re not careful. Rubber tracks should show even wear patterns without excessive cracking or missing lugs. Replacement costs can be substantial, so factor potential undercarriage work into your purchase decision.

Engine condition affects both performance and reliability. Check for excessive smoke, unusual noises, or poor idle quality. Oil analysis reports, when available, provide valuable insight into internal engine condition and potential future maintenance needs.

Our used equipment inventory includes thoroughly inspected machines with detailed condition reports to help you make informed decisions.

The Importance of After-Sales Support

Manufacturer warranty coverage provides the peace of mind every contractor needs. New Takeuchi excavators or New Holland mini excavators typically include comprehensive warranties covering major components for specific time periods or operating hours. Understanding what’s covered and what isn’t can save you headaches later.

Dealer support capabilities make all the difference in your ownership experience. As your local Takeuchi dealer, New Holland dealer, and Hitachi excavator dealer, we maintain certified technicians, a comprehensive parts inventory, and rapid response capabilities. Our Wisconsin locations in Milwaukee, Madison, Green Bay, Butler, and De Pere ensure you’re never far from professional support.

Parts availability keeps your equipment running when you need it most. Established manufacturers like Takeuchi, New Holland, and Hitachi maintain extensive parts networks, ensuring components are readily available. Generic parts might save money upfront, but could compromise performance or void warranty coverage.

Certified technician expertise ensures repairs are done right the first time. Our factory-trained technicians understand Hitachi wheel loaders, Link-Belt excavators, and other equipment systems inside and out. They have access to specialized tools and diagnostic equipment that reduce repair time and ensure work meets manufacturer specifications.

Emergency service capabilities are crucial when project deadlines loom. Our 24/7 emergency support ensures critical issues are addressed promptly, minimizing project delays and keeping your business moving forward.

Training and operator education services help you get the most from your investment. Proper operation techniques, routine maintenance procedures, and safety protocols protect both equipment and operators while optimizing productivity.

Deciding Between Buying and Renting a Small Digger

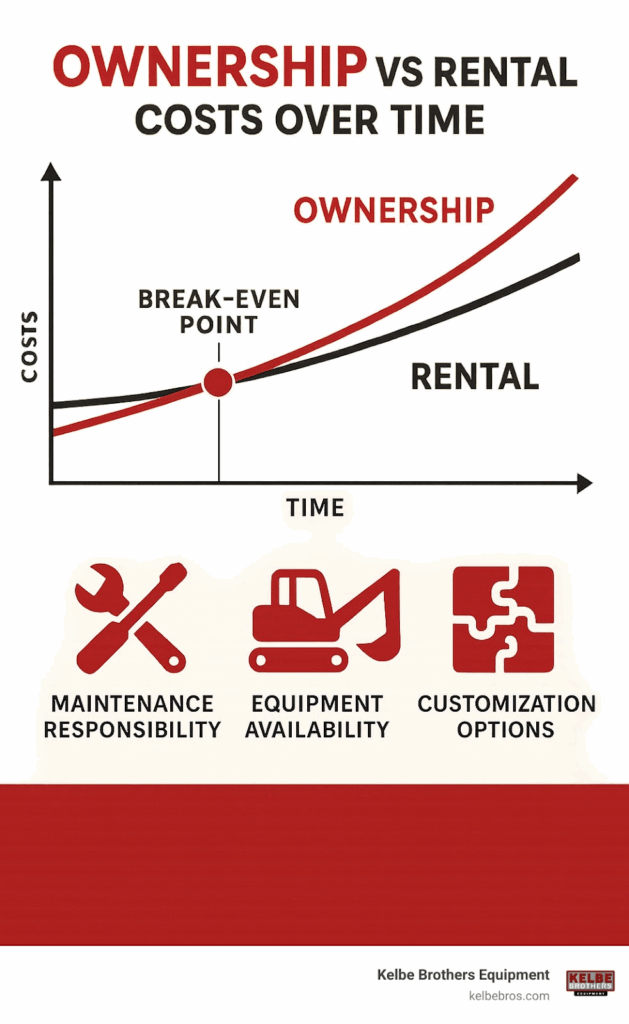

Ownership benefits become clear when you’re using equipment regularly. Constant availability eliminates the frustration of scheduling conflicts – your mini excavators for sale purchase means the machine is ready when you are. Long-term projects particularly benefit from ownership, as rental costs can quickly add up.

Equipment familiarity improves productivity significantly. When operators work with the same Takeuchi compact excavators or New Holland mini excavators consistently, they understand the specific controls, capabilities, and maintenance requirements. This familiarity translates directly into better productivity and fewer operational issues.

Customization options are only available with owned equipment. You can add specific attachments, modifications, or accessories to optimize machines for your particular applications. This customization often improves efficiency and expands what you can accomplish with a single machine.

Rental advantages include flexibility for short-term needs or when you want to try different models before making a purchase decision. Our construction equipment rentals and excavator rental programs let you evaluate various Hitachi excavators, Link-Belt excavators, or other models to see what works best for your specific needs.

Rental agreements typically include maintenance and repair coverage, eliminating unexpected service costs. This can be particularly valuable when you’re testing equipment or handling specialized projects with tight budgets.

Financial considerations vary based on how often you’ll use the equipment. Ownership involves a higher initial investment but lower long-term costs for frequent use. Rental provides lower upfront costs but higher long-term expenses for extended use.

Our rental equipment program offers flexible options for contractors evaluating different models or addressing short-term project needs, while our financing options make ownership more accessible for qualified buyers.

Frequently Asked Questions about Small Diggers

What are the primary applications for a mini excavator?

When you buy small digger equipment, you’re getting a versatile machine that handles an impressive range of tasks. Landscaping projects are where these machines really shine – they can squeeze through standard 36-inch gates to reach backyard areas, dig precise holes for tree planting, and grade surfaces without damaging existing plantings.

Utility trenching keeps mini excavators busy year-round. They dig clean, precise trenches for water lines, electrical conduits, and telecommunications cables. The controlled digging action means you won’t accidentally nick existing utilities or create a mess that takes hours to clean up.

Small-scale demolition projects benefit from the precision these machines offer. With hydraulic breaker attachments, you can break up concrete driveways or remove old foundations without the overkill of bringing in massive equipment. The precise controls let you work carefully around areas you want to preserve.

Foundation work for residential additions, decks, and small buildings is another sweet spot for mini excavators. They dig accurate footings to specification and handle material removal efficiently. I’ve seen contractors complete foundation prep in hours that would take days with manual digging.

Pool installation projects frequently rely on mini excavators for excavation work. The precise control enables accurate digging to specifications while keeping the surrounding lawn intact – something homeowners definitely appreciate.

Material handling rounds out the primary applications. Whether you’re loading trucks, moving gravel, or organizing job sites, various bucket sizes and grapple attachments make these machines incredibly efficient for handling different materials.

What does “zero tail swing” mean on an excavator?

Zero tail swing design means the excavator’s upper structure rotates completely within the width of the tracks. Unlike conventional excavators where the counterweight swings out beyond the track width, zero swing models keep everything contained within the machine’s footprint.

This design provides huge safety advantages in confined spaces. You can rotate the upper structure without worrying about hitting nearby walls, parked vehicles, or other equipment. It’s particularly valuable when working alongside buildings or in crowded residential areas where space is tight.

Property damage risk drops significantly with zero swing excavators. There’s no possibility of accidentally striking cars, structures, or other equipment during normal operation. Homeowners and property managers definitely appreciate this protection, especially in urban construction sites.

Productivity increases in tight spaces because operators can work more efficiently without constantly checking clearance. Instead of focusing on where the tail might swing, operators can concentrate on the actual digging work. This confidence translates directly into faster job completion.

Space utilization is optimized since the machine only needs its track width for operation. This efficiency allows work in areas where conventional excavators would need additional clearance space or simply couldn’t operate at all.

How important is the undercarriage on a used machine?

The undercarriage represents one of the most expensive components to replace on a mini excavator, making its condition absolutely crucial when evaluating used construction equipment for sale. Replacement can cost thousands of dollars, so thorough inspection is essential.

Track condition tells you a lot about how the machine was used and maintained. Rubber tracks should show even wear patterns without excessive cracking, missing lugs, or steel cord exposure. Uneven wear often indicates alignment issues or worn undercarriage components that need attention.

Roller condition affects both track life and machine stability. Worn rollers cause irregular track movement and accelerated track wear. Check for excessive play, damaged rubber, or worn bearing surfaces that signal replacement needs.

Sprocket wear impacts drive efficiency and track longevity. Examine sprocket teeth for excessive wear, damage, or missing segments. Worn sprockets cause poor track engagement and can lead to track damage or even derailment during operation.

Frame condition deserves careful inspection for cracks, excessive wear, or impact damage. The undercarriage frame supports the entire machine weight and transmits driving forces, making structural integrity essential for safe operation.

Regular maintenance significantly extends undercarriage life. Proper track tension, regular cleaning, and prompt attention to wear issues prevent premature failure and keep operating costs manageable. A well-maintained undercarriage often indicates responsible ownership throughout the machine’s life.

Conclusion: Finding the Right Equipment Partner for Your Needs

When you buy small digger equipment, you’re making an investment that can transform how you tackle projects and boost your bottom line. The compact machines we’ve explored – from Takeuchi’s precision zero swing excavators to New Holland’s versatile mini excavators, Hitachi’s fuel-efficient wheel loaders, and Link-Belt’s robust construction – each bring unique strengths to different job sites.

Understanding the key features we’ve discussed really matters. Operating weight, digging depth, hydraulic performance, and undercarriage design aren’t just technical specifications – they’re the factors that determine whether your machine will handle your specific jobs efficiently and reliably for years to come.

The choice between new and used equipment depends on your situation, but one thing remains constant: comprehensive after-sales support protects your investment. Having access to certified technicians, genuine parts, and emergency service when you need it most can make the difference between a minor hiccup and a major project delay.

As a fourth-generation, family-owned company serving Wisconsin contractors for over 60 years, we’ve learned that success comes from understanding your challenges and being there when you need us. Our locations in Milwaukee, Madison, Green Bay, Butler, and De Pere mean you’re never far from expert support.

Our team brings decades of hands-on experience to help you steer equipment selection, financing options, and ongoing maintenance needs. We believe in rapid response and hassle-free service because we know that when your equipment is down, your projects suffer.

Whether buying makes sense or renting fits your needs better, we’re here to provide the right solution. Sometimes the best approach combines both – owning core equipment while renting specialized machines for specific projects.

The construction equipment industry can be complicated, but partnering with the right dealer doesn’t have to be. We’re committed to making your equipment decisions straightforward and your ownership experience smooth.

Ready to explore your options? Find your next small digger here and find how the right compact equipment can deliver improved productivity and better results for your operations.