Construction machinery forms the backbone of every successful building project, from residential developments to major infrastructure. These powerful machines enable contractors to move earth, lift heavy materials, and complete projects with efficiency and precision.

What is Construction Machinery?

- Heavy equipment is designed for construction tasks

- Includes excavators, loaders, dozers, and specialized vehicles

- Operates through mechanical advantage to multiply force

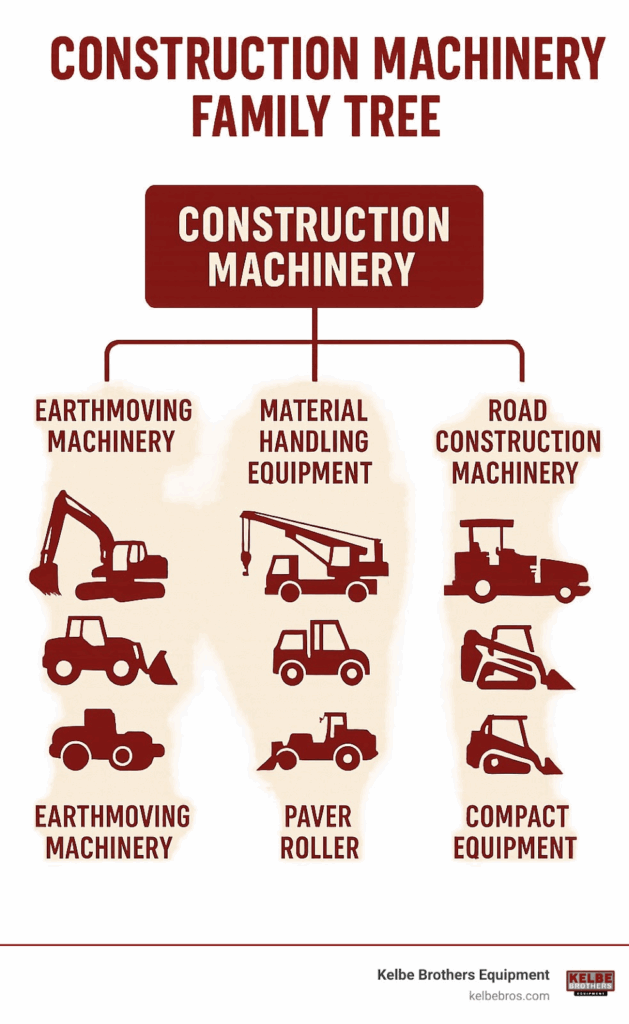

- Categorized by function: earthmoving, material handling, road building

- Ranges from compact mini-excavators to massive mining equipment

The global construction equipment market is dominated by industry giants like Komatsu and Hitachi, who together with other top manufacturers account for over 60% of total sales. Modern machines increasingly feature electrification, automation, and telematics systems that boost productivity while reducing environmental impact.

The construction machinery industry has evolved significantly since the first mass-produced Fordson tractor in 1917. Today’s equipment combines powerful hydraulics with sophisticated control systems, enabling operators to perform complex tasks with precision and safety.

At Kelbe Brothers Equipment, we understand that choosing the right machinery can make or break your project timeline and budget. Whether you’re looking for excavators, wheel loaders, or compact track loaders, the right equipment can dramatically improve your jobsite efficiency.

I’m Jeffrey J. Miller, President of Kelbe Brothers Equipment, bringing renewed energy and vision to our company during a time of industry transition in the construction machinery sector. Under my leadership, we’ve expanded our equipment offerings with top brands like Hitachi, Link-Belt, New Holland, and Takeuchi to help Wisconsin contractors tackle their toughest challenges.

What Is Construction Machinery?

Construction machinery is the backbone of modern building projects—powerful vehicles and equipment designed specifically for construction tasks. From digging foundations to moving mountains of earth, these machines transform what would be back-breaking manual labor into efficient, productive work.

Think of construction machinery as force multipliers. Through clever mechanical systems, they allow a single operator to accomplish what once required dozens or even hundreds of workers. At their core, these machines combine five fundamental systems working in harmony:

The implement is the business end—the bucket that digs, the blade that pushes, or the ripper that tears through hard ground. Your traction system determines how the machine moves across the jobsite, whether on specially designed off-highway tires or rugged tracks. The structure provides the framework that holds everything together, while the powertrain delivers the muscle. Finally, the control systems let operators harness all this power with precision.

Those massive tires you see on construction machinery aren’t just oversized versions of what’s on your car. They’re specially engineered for harsh conditions and classified into specific service types: compactor, earthmover, grader, loader, log-skidder, and mining/logging. Each type has unique tread patterns and construction to provide the right traction for specific applications.

| System | Function | Examples | Considerations |

| Implements | Working tools that interact with materials | Buckets, blades, hammers, augers | Task-specific design, wear resistance, hydraulic compatibility |

| Traction | Movement and stability systems | Tracks, wheels, outriggers | Ground pressure, terrain adaptability, traction in various conditions |

Construction Machinery Through the Ages

The story of construction machinery is really the story of human innovation. Our ancestors started with simple stone tools and wooden levers, gradually developing more sophisticated ways to move earth and materials.

The Romans used pulley systems, but the real game-changer came with the Industrial Revolution. Steam-powered shovels appeared in the 1800s, bringing mechanical muscle to construction sites for the first time. These early machines, while primitive by today’s standards, revolutionized what was possible.

A major milestone came in 1917 with the Fordson tractor—the first mass-produced heavy machine. Around the same time, continuous-track vehicles like the 1901 Lombard Steam Log Hauler were proving that off-road mobility could be dramatically improved.

By the mid-20th century, diesel engines had taken over, offering more power and efficiency. The 1970s saw hydraulic systems become standard, giving operators unprecedented precision and force. According to scientific research on equipment history, these innovations dramatically accelerated construction capabilities.

Today, we’re witnessing another revolution with hybrid and fully electric drives. Since 2019, major manufacturers have introduced commercial electric-powered equipment that offers reduced emissions, quieter operation, and potentially lower running costs, pointing toward a greener future for the industry.

Core Types & Tasks

At Kelbe Brothers Equipment, we’re proud to offer Wisconsin contractors access to the highest quality construction machinery across all major categories. Here’s what makes up the core fleet on modern jobsites:

Excavators are the versatile diggers you’ll see on almost every construction site. With their distinctive boom, stick, and bucket mounted on a rotating platform, they excel at trenching, digging foundations, and precise material handling. Our Hitachi Excavators and Link-Belt Excavators deliver the reliability Wisconsin contractors demand.

Wheel Loaders feature a front-mounted bucket on an articulated frame, making them ideal for loading materials, clearing sites, and handling bulk materials. Our Hitachi Wheel Loaders and New Holland Wheel Loaders combine power with operator comfort.

Skid Steers are the compact workhorses of construction, using skid steering to turn within their own footprint—perfect for tight spaces. The New Holland 200 Series offers exceptional versatility and performance.

Compact Track Loaders like the Takeuchi Compact Track Loaders provide superior traction in soft or uneven terrain thanks to their track system instead of wheels.

Mini Excavators from Takeuchi and New Holland bring big digging power to small spaces, perfect for urban worksites and landscaping.

Material Handlers, like the specialized Link-Belt Material Handlers, are designed for efficiently processing materials such as scrap, logs, or bulk goods.

Crawler Dozers feature tracks and a front-mounted blade, making them ideal for pushing large quantities of material, grading, and land clearing.

Each machine type brings unique capabilities to your jobsite, and selecting the right equipment for your specific application is where our 4th-generation expertise truly shines.

Meet the Machines: Functions, Sizes, & Specialties

When you step onto a busy construction site, you’ll see a symphony of construction machinery working together to transform plans into reality. Each machine plays a unique role, from carving precise trenches to lifting massive loads with surprising grace.

These powerful tools come in all shapes and sizes, each designed to tackle specific challenges you’ll face on the jobsite. What makes today’s equipment truly remarkable is its versatility – with the right attachments, a single machine can transform from a precision digger to a powerful demolition tool in minutes. This adaptability helps you accomplish more with fewer machines, saving both money and logistical headaches.

Think about what makes each machine special: the raw digging power of excavators biting into tough soil, the rhythmic loading cycles of wheel loaders filling trucks with perfect precision, or the careful grading of dozers creating exactly the right slope. When demolition calls, hydraulic hammers make short work of concrete, while specialized attachments handle delicate landscaping with surprising finesse.

At Kelbe Brothers Equipment, we don’t just sell machines – we help you find the perfect match for your specific projects. Our team understands Wisconsin job conditions and can guide you to equipment that will perform at its best in your unique applications.

Excavators – Hitachi & Takeuchi Spotlight

The beating heart of most construction sites is the trusty excavator. We’re proud to offer both Hitachi and Takeuchi excavators, giving you options that match your specific needs.

Hitachi Excavators have earned their reputation for rock-solid reliability and hydraulic systems that deliver both power and finesse. From mid-size utility machines to larger production models, Hitachi’s lineup handles everything from trenching for utilities to major excavation projects. What makes them special is the balance they strike – tremendous digging force when you need it, yet fingertip control for precision work in tight spots.

For smaller spaces and specialized work, Takeuchi Compact Excavators shine. These machines pack impressive capability into a compact footprint, making them perfect for urban projects where space comes at a premium. We especially love Takeuchi’s zero swing models for working near buildings or in confined areas – the counterweight stays within the track width during rotation, eliminating the worry of accidentally damaging surrounding structures.

Both manufacturers offer an impressive range of attachments that transform these diggers into multi-purpose tools. Buckets for every material type, powerful hydraulic hammers for breaking concrete, precision grapples for material handling, and earth-drilling augers – all quickly interchangeable to match the task at hand.

When selecting your excavator, we’ll help you balance depth versus reach specifications. Maximum digging depth tells you how far down you can excavate, while reach capabilities determine how far you can extend to place material or work across obstacles.

For keeping your excavator running at peak performance, our Parts department stocks genuine OEM components for both brands.

Wheel Loaders – Hitachi & New Holland Powerhouses

When it comes to moving materials efficiently, wheel loaders are the workhorses you’ll depend on daily. Our lineup features outstanding options from both Hitachi and New Holland.

Hitachi Wheel Loaders blend impressive performance with operator-friendly features and fuel-saving technology. Their Z-bar linkage systems generate exceptional breakout force, powering through dense materials like clay and rock with ease. What sets Hitachi loaders apart is their legendary reliability, robust powertrains, and heavy-duty components designed to deliver consistent performance even in the harshest Wisconsin winters.

New Holland Wheel Loaders bring innovation and productivity to your material handling operations. From compact utility models to production-class machines for high-volume work, New Holland’s range covers every application. Their smart features, like automatic powershift transmissions and responsive hydraulics, help operators work faster while burning less fuel – a winning combination for your bottom line.

Both brands offer various bucket capacities carefully matched to different material densities and production needs. Quick-coupler systems let your operators switch from buckets to forks or specialized attachments without leaving the comfort of their cab, maximizing productive time.

In the real world of construction, load-out efficiency makes a huge difference to your productivity. Both our Hitachi and New Holland loaders excel here, with helpful features like return-to-dig automation, height limiters, and smooth controls that reduce operator fatigue during long shifts loading trucks.

Compact Track & Skid-Steer Loaders

When versatility meets maneuverability, you get compact track loaders and skid steers – the Swiss Army knives of construction machinery. Our selection includes top performers from New Holland and Takeuchi.

New Holland 200 Series skid steers and compact track loaders deliver big performance in small packages. Their vertical lift design maximizes both height and capacity, making truck loading and material placement a breeze. We particularly love the Super Boom® design that provides exceptional forward reach at full height – a real advantage when placing materials in hard-to-reach spots.

When ground conditions get challenging, Takeuchi Compact Track Loaders prove their worth. Their wide tracks distribute weight evenly, dramatically reducing ground pressure and allowing you to work effectively in soft soil, mud, or sandy conditions that would stop wheeled equipment cold. Operators appreciate Takeuchi’s pilot controls for precise operation and high-flow hydraulic systems that power even the most demanding attachments.

The true magic of these compact machines lies in their incredible versatility. With dozens of available attachments – from standard buckets and blades to specialized tools like trenchers, augers, and brooms – a single compact loader can handle nearly any task on your jobsite. This makes them especially valuable for smaller contractors who need maximum capability from every equipment dollar.

For projects where ownership doesn’t make sense, our Rental Equipment program offers both skid steers and compact track loaders, giving you access to these versatile machines without long-term commitment.

Material Handlers & Backhoes

For specialized material handling and versatile digging operations, we offer premium solutions from Link-Belt and New Holland.

Link-Belt Material Handlers are purpose-built for efficient processing in applications like scrap yards, waste management facilities, and log handling operations. These specialized machines feature lifted cabs for superior visibility, extended reach booms for maximum working range, and purpose-designed attachments like grapples and magnets. Link-Belt’s responsive hydraulic systems deliver the precise control and quick cycle times needed to maximize productivity in material transfer operations.

New Holland Tractor Loader Backhoes offer three machines in one versatile package. The front loader handles material moving and loading, the rear backhoe tackles trenching and excavation, and the tractor itself provides mobility and power for both ends. Their curved boom design improves both digging performance and reach, while four-wheel drive systems ensure excellent traction in challenging Wisconsin conditions.

These multi-function machines offer exceptional value for contractors who need versatility without maintaining multiple specialized pieces of equipment. A single operator can switch between loading, digging, and material handling tasks in moments, improving jobsite efficiency and stretching your equipment budget further.

Evolution, Innovation & Sustainability in Construction Machinery

The world of construction machinery is experiencing a remarkable change, blending traditional power with cutting-edge technology. Today’s innovations focus on making equipment smarter, cleaner, and more efficient than ever before.

Electrification is no longer just a concept but a growing reality on job sites across Wisconsin. Major manufacturers are introducing fully or partially electric machines that deliver impressive performance without the emissions. These quieter, cleaner machines aren’t just good for the environment – they can save you money through reduced fuel costs and simpler maintenance requirements.

Automation has moved from science fiction to job-site fact. From helpful features like return-to-dig on wheel loaders (which automatically positions your bucket for the next load) to sophisticated grade control systems that maintain perfect digging depths, today’s construction machinery works smarter so your operators don’t have to work harder. Some manufacturers are even developing fully autonomous machines for repetitive tasks, though the skilled operator remains irreplaceable for complex work.

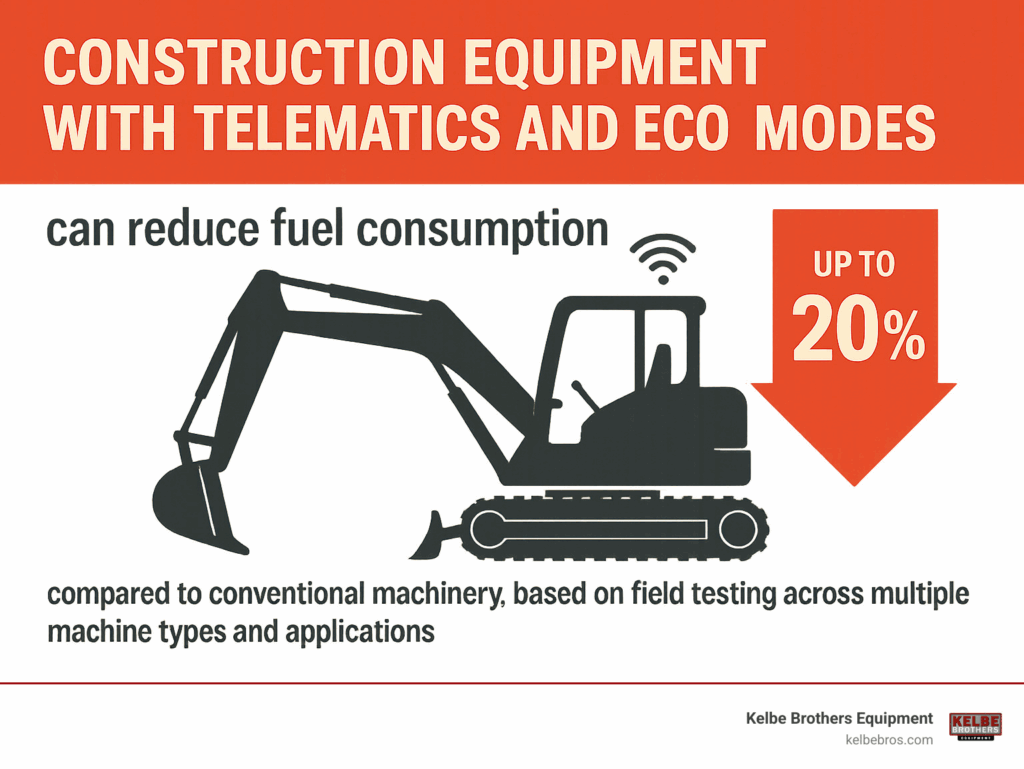

Telematics systems have revolutionized fleet management by providing real-time insights previously impossible to obtain. These systems track everything from location and operating hours to fuel consumption and maintenance alerts. At Kelbe Brothers, we’ve seen how this data helps our customers optimize equipment utilization, schedule preventive maintenance at convenient times, and identify opportunities for operator training – all contributing to healthier bottom lines.

Sustainability initiatives extend beyond just alternative power sources. Low-carbon fuels offer immediate environmental benefits for conventional equipment. Smart fleet right-sizing ensures you’re matching machines precisely to tasks, avoiding the inefficiency of oversized equipment. Even operator ergonomics plays a role in sustainability – comfortable operators are more productive and make fewer mistakes.

We’re committed to keeping Wisconsin contractors at the forefront of these innovations through our premium equipment brands. Many of our machines connect seamlessly to Global e-Service platforms, giving you comprehensive control over your fleet’s performance.

Digital Construction Machinery & Telematics

Remember when knowing how your machine was performing meant climbing underneath it with a flashlight? Those days are gone. Today’s digital construction machinery connects directly to cloud-based platforms that monitor everything happening inside your equipment.

Hitachi’s ConSite system is like having a diagnostic technician working 24/7 on your fleet. It delivers detailed monthly reports on machine health, highlighting potential issues before they cause breakdowns. Our customers tell us these proactive alerts have saved them thousands in repair costs while extending their equipment’s productive life.

GPS fleet tracking transforms how you manage your jobsites. Need to know exactly where your excavator is right now? Want an alert if equipment leaves a designated area? Modern telematics makes it possible. For companies juggling multiple projects, this visibility is invaluable for optimizing equipment deployment and preventing unauthorized use.

Predictive maintenance might be the most exciting application of all this data. By analyzing patterns in hydraulic pressures, temperatures, and engine loads, these systems can identify potential failures days or weeks before they occur. Instead of responding to unexpected breakdowns, you can schedule maintenance during planned downtime – a game-changer for project scheduling and cost control.

Our Service technicians can now remotely access machine data, often diagnosing issues without an initial site visit. This capability cuts response time dramatically and improves our first-time fix rates, getting your equipment back to work faster when problems do arise.

Green Machines & Future Tech

The future of construction machinery is increasingly green, with innovations that protect both the environment and your profitability.

Battery-electric loaders are making inroads on jobsites where zero emissions and low noise levels matter most. These machines shine in indoor demolition, urban construction, and environmentally sensitive areas. While they currently come with higher upfront costs, the operational savings and ability to work in restricted environments can make them smart investments for specific applications.

Hybrid excavators represent a practical middle ground, combining diesel engines with electric systems. The engine generates electricity that powers electric motors for swing and other functions – an arrangement that improves fuel efficiency while maintaining the power and endurance needed for demanding applications. Many contractors report 15-30% fuel savings with these hybrid designs.

Today’s construction machinery is increasingly designed with its entire lifecycle in mind. Recyclable components reduce waste and conserve valuable resources when machines reach the end of their service life. This whole-lifecycle approach reflects the industry’s growing commitment to sustainability.

Practical features like idle-shutdown systems automatically turn off engines after a predetermined period of inactivity, eliminating wasted fuel and unnecessary emissions. The smartest systems can distinguish between productive idle time (when hydraulics are being used but the machine isn’t moving) and unproductive idling.

Eco-modes have become standard on most new equipment, optimizing engine and hydraulic settings to reduce fuel consumption during less demanding tasks. These intelligent systems reduce engine speed and adjust hydraulic pump flow to match actual requirements, saving fuel without compromising productivity when full power isn’t needed.

At Kelbe Brothers Equipment, we’re excited to help Wisconsin contractors steer these innovations. Whether you’re looking to reduce your environmental footprint, cut operating costs, or simply stay ahead of the technology curve, we’ve got the expertise and equipment selection to make it happen. Our team can help you evaluate which of these technologies makes the most sense for your specific applications and budget.

Selection, Operation & Maintenance Best Practices

Getting the most from your construction machinery starts long before you turn the key. The path to success begins with selecting the right equipment, continues through proper operation, and depends on consistent maintenance throughout the machine’s life.

Smart contractors know that matching equipment specs to job requirements saves both time and money. An oversized machine burns unnecessary fuel, while an undersized one struggles to keep pace with production demands. This careful matching process is something we’ve helped Wisconsin contractors with for four generations at Kelbe Brothers.

The versatility of modern equipment often comes down to attachment selection. A single excavator can transform from a precision trenching tool to a powerful demolition machine simply by swapping attachments. With the right quick coupler system, these changes can happen in minutes rather than hours, keeping your crew productive.

“The best machine is only as good as its operator,” is something my grandfather used to say, and it remains true today. Well-trained operators not only work faster but also extend equipment life through proper technique. They know when to push a machine and when to ease back, saving you thousands in premature wear and unnecessary fuel consumption.

Safety isn’t just about compliance—it’s about getting everyone home at the end of the day. OSHA requirements for protective structures, alarms, and operator qualifications provide a foundation, but a true safety culture goes beyond the minimum. We’ve seen how the best contractors make safety a cornerstone of their operations, with impressive results in both human and financial terms.

When we talk about lifecycle management with our customers, we encourage them to look beyond the initial price tag. A quality machine might cost more upfront but deliver thousands more productive hours while requiring fewer repairs. This long-view approach often leads to better equipment decisions and healthier bottom lines.

Choosing the Right Construction Machinery

Finding your perfect equipment match means balancing several critical factors:

Project scope should drive your equipment selection. The residential contractor who primarily digs foundations needs different capabilities than the utility contractor installing miles of pipeline. At Kelbe Brothers, we’ll help you analyze your typical projects to identify the ideal machine size and configuration.

Ground conditions in Wisconsin can vary dramatically, from rocky hillsides to soft wetlands. These conditions directly impact your choice between wheels and tracks. While wheeled machines offer speed and mobility on improved surfaces, tracked equipment provides superior flotation and stability in challenging terrain. Many of our customers maintain mixed fleets to handle Wisconsin’s diverse conditions.

Transportation between job sites is a practical concern that’s often overlooked during equipment selection. We help customers consider height, width, and weight restrictions that might affect their ability to move machinery efficiently. Sometimes the perfect solution is a slightly smaller machine that doesn’t require specialized hauling permits.

As emissions regulations continue to evolve, equipment choices must adapt as well. Newer Tier 4 Final engines offer cleaner operation but may require ultra-low sulfur diesel and more sophisticated maintenance. In some urban zones, electric equipment is becoming not just an option but a requirement. Our New Equipment inventory includes machines that meet the latest standards while delivering the performance Wisconsin contractors demand.

Operating for Productivity & Safety

The most successful operators start every shift with thorough pre-start checks. This simple routine—inspecting fluid levels, checking tracks or tires, examining hydraulic components, and testing safety systems—can prevent costly mid-day breakdowns and dangerous failures. We encourage all our customers to make these checks a non-negotiable part of their daily routine.

Modern construction machinery has accepted technology that dramatically improves safety. The 360° camera systems now available on many Hitachi and Link-Belt excavators eliminate dangerous blind spots, giving operators complete situational awareness. When an operator can see everything around the machine, the entire jobsite becomes safer.

Grade control technology has revolutionized excavation work. Whether it’s the simple depth indicators on our Takeuchi mini excavators or the advanced GPS systems available on larger Hitachi models, these tools help operators work with unprecedented precision. The result? Less rework, lower fuel consumption, and faster project completion.

Operator comfort isn’t a luxury—it’s a productivity essential. Today’s equipment cabs feature ergonomic controls, effective climate systems, and reduced noise levels specifically designed to combat fatigue. A comfortable operator maintains focus and productivity throughout the shift, maximizing your return on equipment investment.

Clear communication protocols between machine operators and ground personnel prevent accidents and improve efficiency. Whether using hand signals, radio systems, or pre-job briefings, everyone on site needs to understand how machines will move and work. This shared understanding creates a safer, more productive environment.

Keeping Your Fleet Running

Following manufacturer-recommended maintenance schedules is the single most effective way to maximize equipment life and minimize unexpected downtime. These preventive schedules—typically organized by operating hours—address critical systems before they fail. Our service department helps customers develop and implement these maintenance programs for every brand we carry.

Regular fluid analysis provides an early warning system for potential problems. By testing engine oil, hydraulic fluid, and coolant, we can detect contaminants and wear metals before they cause catastrophic failures. This predictive approach turns major repairs into minor adjustments, saving both time and money.

When components do need replacement, remanufactured parts often provide the best value. These factory-rebuilt items typically cost 20-40% less than new components while offering similar reliability and warranties. Our parts department stocks a wide selection of both new and reman options to fit your budget and timeline.

Wisconsin winters demand special equipment care. Proper winterization—including correct coolant concentration, fuel conditioning, battery maintenance, and hydraulic system protection—prevents freeze damage and ensures reliable cold-weather operation. Our service team can help prepare your fleet for winter’s challenges.

For equipment issues beyond routine maintenance, our factory-trained technicians provide expert service for Hitachi, Link-Belt, New Holland, and Takeuchi machinery. With extensive parts inventory and field service capabilities, we keep Wisconsin contractors working even when challenges arise. And when replacement makes more sense than repair, our Used Equipment inventory offers quality pre-owned alternatives.

The Road Ahead for Construction Machinery

The construction machinery industry stands at an exciting crossroads, with promising growth opportunities despite economic uncertainties. Infrastructure investments and steady housing demand continue to fuel market expansion, creating a positive outlook for Wisconsin contractors.

One of the most significant challenges facing our industry is workforce development. As our experienced operators reach retirement age, finding and training the next generation becomes increasingly critical. This demographic shift is happening just as equipment becomes more technologically advanced, requiring a whole new set of skills from today’s operators.

At Kelbe Brothers Equipment, we understand these challenges firsthand. The shortage extends beyond operators to maintenance technicians as well, with today’s sophisticated electronic systems and diagnostic tools demanding specialized knowledge. We’re deeply committed to supporting our Wisconsin customers through these transitions with comprehensive training resources and technical support that keeps your team productive.

The evolution toward autonomous operation continues to accelerate. While we’re not yet seeing fully autonomous construction sites, many of our newest machines feature impressive assisted operation capabilities that boost productivity and safety. These technologies help less experienced operators work more efficiently while reducing fatigue for veterans.

Recent global events have highlighted the importance of supply-chain resilience. Equipment manufacturers have responded by diversifying component sources and strengthening distribution networks. This focus on reliability helps ensure that when you need parts or new equipment, you won’t face extended delays that impact your project timelines.

Training Tomorrow’s Operators

The construction industry is embracing innovative approaches to develop skilled equipment operators who can maximize the potential of modern construction machinery.

Virtual reality simulators have revolutionized operator training, creating safe, cost-effective learning environments. These sophisticated systems allow new operators to develop fundamental skills before handling actual equipment worth hundreds of thousands of dollars. The ability to simulate challenging weather conditions, difficult terrain, and emergency scenarios provides invaluable experience without risk to personnel or equipment.

Structured certification pathways offer clear progression from basic operation to advanced techniques. These comprehensive programs typically blend classroom learning with supervised hands-on time and formal skill assessments. This systematic approach ensures operators develop competence across all aspects of machine operation.

Nothing replaces the value of experienced mentorship. When seasoned operators share their knowledge with newcomers, they pass along invaluable insights that no manual can capture. These mentoring relationships help new operators understand the subtle techniques that lead to efficient operation and longer equipment life.

Throughout all training approaches, safety culture remains the foundation. We emphasize situational awareness, clear communication protocols, and proper machine handling techniques. This focus not only protects your team and equipment but also reduces insurance costs and prevents costly downtime from accidents.

Industry Outlook & Challenges

As the construction machinery industry evolves toward greater sustainability and technological sophistication, several significant challenges have emerged.

The growing adoption of battery-electric equipment creates new logistical considerations for job sites. High-capacity charging stations often require substantial electrical service upgrades—a particular challenge for remote locations or larger equipment fleets. Forward-thinking contractors are already incorporating these power requirements into their site planning.

As more electric machines enter service, battery recycling becomes increasingly important. Manufacturers are developing comprehensive programs to ensure responsible end-of-life handling of these components, recovering valuable materials while minimizing environmental impact. This lifecycle approach reflects the industry’s growing commitment to sustainability beyond just reducing emissions.

The connected nature of modern equipment raises important data security considerations. Today’s telematics systems collect valuable operational data that improves efficiency and maintenance planning, but this information must be protected from unauthorized access and potential cyber threats. Manufacturers continue to strengthen security protocols to address these concerns.

Regulatory trends continue pushing toward stricter emissions standards and improved safety features. Equipment manufacturers face the ongoing challenge of balancing these requirements with performance, reliability, and cost considerations to deliver machines that satisfy both regulatory compliance and customer needs.

Despite these challenges, the future of construction machinery looks remarkably bright. Continued innovation drives impressive improvements in productivity, safety, and environmental performance, creating opportunities for Wisconsin contractors who accept these advancements.

Frequently Asked Questions about Construction Machinery

What are the main differences between excavators and mini-excavators?

When contractors ask us about choosing between standard and mini excavators, we explain that while they share the same basic design concept, they’re built for very different jobs.

Size and weight are the most obvious differences. Standard construction machinery like our Hitachi and Link-Belt excavators typically weigh between 15 and 90 tons, while Takeuchi and New Holland mini excavators are much lighter at just 1 to 10 tons. This significant weight difference means mini excavators can often be transported on standard trailers without special permits – a real advantage for contractors working across multiple sites.

The working capacity varies dramatically, too. A 20-ton Hitachi excavator might dig to depths exceeding 20 feet with impressive bucket capacity, while a compact Takeuchi mini reaches about 10-12 feet maximum. This makes standard excavators ideal for major earthmoving, while mini-excavators excel in precision work.

We’ve found that our Wisconsin customers choose mini excavators primarily for confined spaces – urban construction, residential projects, and even interior demolition work. Their smaller footprint and reduced ground pressure let them work in areas where larger machines simply can’t fit or would damage finished surfaces.

Many of our Takeuchi mini excavators feature zero tail swing designs, meaning the counterweight doesn’t extend beyond the tracks during rotation. This prevents accidental damage in tight quarters, though it typically reduces lifting capacity compared to conventional designs.

From a practical business perspective, mini excavators generally have lower purchase prices, transportation costs, and fuel consumption, making them smart choices when their capabilities align with your project needs.

How do telematics systems improve equipment uptime?

Telematics has completely changed how our customers manage their construction machinery fleets, and we’ve seen how these systems help prevent costly downtime.

Modern telematics provides real-time preventive maintenance alerts by tracking operating hours and automatically notifying owners when scheduled service is due. This simple feature ensures critical maintenance isn’t overlooked during busy seasons – something that happens all too often in the construction industry.

The continuous health monitoring capability is particularly valuable. By constantly checking key parameters like engine temperature, oil pressure, and hydraulic system performance, these systems can spot abnormal conditions before they cause catastrophic failures. One of our customers recently avoided a major hydraulic pump failure because their system detected unusual pressure fluctuations early.

When problems do occur, fault code reporting makes a huge difference. When a machine’s onboard computer detects an issue, telematics systems immediately report the specific fault code to our service department, allowing our technicians to arrive prepared with the right parts and tools, often fixing problems in a single visit.

We’ve also helped contractors optimize their fleets through utilization analysis. By tracking actual working hours versus idle time, we can identify machines that are overworked (risking premature wear) or underused (representing inefficient capital investment).

Additional features like geofencing and fuel monitoring protect your investment by alerting you to unauthorized use and preventing fuel theft, unfortunately, still common on construction sites.

At Kelbe Brothers Equipment, we help Wisconsin contractors implement and leverage these powerful systems to maximize reliability and productivity across their fleets.

What sustainability features should I look for in new construction machinery?

Today’s construction machinery offers impressive sustainability features that not only reduce environmental impact but often deliver significant operational cost savings too.

Tier 4 Final/Stage V engines represent the current gold standard in emissions technology. These advanced power plants dramatically reduce particulate matter and nitrogen oxide emissions compared to older engines. All our new Hitachi, Link-Belt, New Holland, and Takeuchi equipment meets these stringent standards.

Look for machines with selectable eco modes that optimize fuel efficiency during less demanding tasks without sacrificing power when needed. We’ve had customers report 15-20% fuel savings just by properly using these features on their New Holland and Hitachi equipment.

Auto-idle and auto-shutdown capabilities might seem simple, but they make a huge difference in fuel consumption. These systems automatically reduce engine speed during inactivity or shut down the engine after a predetermined idle period, eliminating wasted fuel and unnecessary emissions.

For certain applications, particularly indoor work or noise-sensitive areas like hospitals or schools, electric or hybrid options offer zero local emissions and significantly reduced noise. The technology in this area is advancing rapidly, with more powerful and longer-lasting battery systems becoming available.

Efficient hydraulic systems with load-sensing capabilities, regenerative circuits, and optimized pump control reduce energy waste and improve fuel efficiency. Hitachi excavators are particularly known for their hydraulic efficiency.

Many contractors working near waterways or in environmentally protected areas choose machines that can use biodegradable hydraulic fluids. These environmentally friendly alternatives reduce impact in case of leaks or spills.

Telematics for efficiency optimization helps operators and fleet managers identify opportunities for improved efficiency through detailed reporting on machine utilization, idle time, and fuel consumption patterns.

When evaluating your next equipment purchase, these sustainability features often pay for themselves through reduced operating costs while helping you meet increasingly strict environmental requirements on sensitive projects.

Conclusion

The world of construction machinery never stands still. From powerful hydraulics to smart telematics systems, today’s equipment gives Wisconsin contractors incredible tools to finish projects efficiently, safely, and with less environmental impact than ever before.

At Kelbe Brothers Equipment, our connection to the construction machinery industry runs deep. As a fourth-generation family business, we’ve watched equipment evolve from basic mechanical machines to today’s sophisticated, computer-improved powerhouses. This unique perspective helps us guide contractors to the perfect equipment match, whether that’s a rugged Hitachi excavator for major earthmoving, a versatile New Holland compact track loader for material handling, or a nimble Takeuchi mini excavator for precise work in tight spaces.

We understand the challenges facing today’s construction professionals. Finding skilled operators is getting harder. Environmental regulations are tightening. Project timelines are shrinking. But these challenges create opportunities for contractors who accept new technologies and equipment solutions. When you partner with Kelbe Brothers, you’re not just buying machinery – you’re gaining access to decades of expertise in equipment selection, application, and maintenance.

Ready to explore your options? Browse our comprehensive inventory of new equipment featuring industry-leading brands like Hitachi, Link-Belt, New Holland, and Takeuchi. Our experienced team will help you find the perfect match for your specific project requirements and long-term business goals.

With locations across Wisconsin – including Milwaukee, Madison, Green Bay, Butler, and De Pere – we’re always close to your jobsite. When you need us, we’re there with rapid response service, 24/7 emergency support, and flexible financing options that make equipment acquisition straightforward.

The future of construction machinery looks bright, with ongoing innovations improving everything from fuel efficiency to operator comfort. As your trusted equipment partner, we’ll help you steer these changes and keep your business moving forward. After all, your success is our success – and has been for four generations.