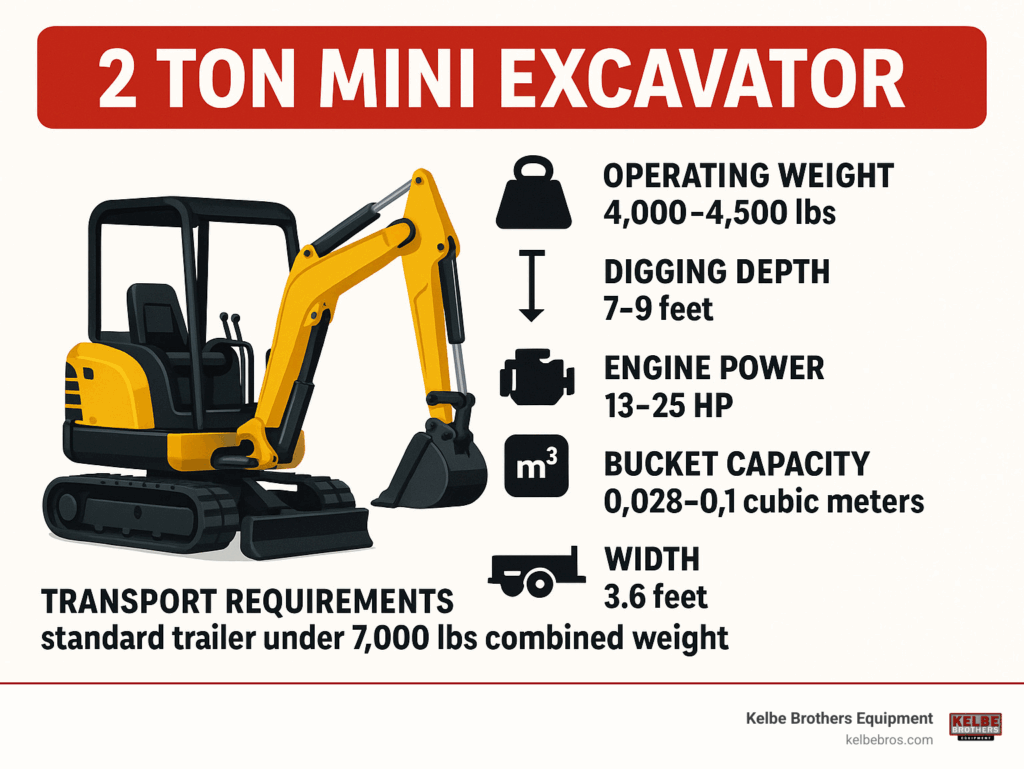

2 ton mini excavators typically weigh 4,000-4,500 pounds (1,800-2,000 kg) and offer these key specifications:

- Digging depth: 7-9 feet

- Engine power: 13-25 HP diesel engines

- Bucket capacity: 0.028-0.1 cubic meters

- Width: Approximately 3.6 feet (1,100 mm)

- Transport requirements: Standard trailer (combined weight under 7,000 lbs)

When construction demands meet spatial constraints, the 2 ton mini excavator emerges as the perfect middle-ground solution. These compact powerhouses deliver impressive digging capabilities while maintaining the maneuverability needed for tight spaces and urban job sites. With their ability to access confined areas where larger equipment simply can’t operate, these machines have revolutionized efficiency on smaller construction and landscaping projects.

The versatility of a 2 ton mini excavator extends far beyond basic digging. From trenching and grading to demolition and landscaping, these machines handle diverse tasks with precision and reliability. Their compact footprint minimizes site disruption while still providing enough power for serious earthmoving operations. Most models feature zero-tail swing designs, making them ideal for working alongside buildings, in backyard renovations, or on busy urban construction sites.

As President of Kelbe Brothers Equipment, I’ve helped countless contractors find the right 2 ton mini excavator for their specific needs, witnessing how these versatile machines transform productivity on job sites across Wisconsin. Our decades of experience in the construction equipment industry has positioned us to provide expert guidance on selecting the perfect compact excavator for any application.

Why Choose a 2 Ton Mini Excavator for Your Next Project

Ever tried squeezing a full-sized excavator through a garden gate? Not happening! That’s where the 2 ton mini excavator shines brightest. These compact powerhouses are the perfect solution when your project demands serious digging capability but space is at a premium.

Working in urban environments or residential backyards requires equipment that can steer tight spaces without sacrificing performance. At just about 3.6 feet wide, a 2 ton mini excavator slips through standard gates and operates comfortably in spaces that would leave larger machines stuck at the curb. With digging depths of 6-7 feet, these machines handle utility trenching, foundation prep, and landscape changes with impressive precision.

Don’t let their size fool you – these machines are fuel-sipping workhorses. Most 2 ton mini excavators feature efficient diesel engines from trusted manufacturers like Kubota or Yanmar. You’ll get all the power you need for demanding jobs while keeping your fuel costs in check. For contractors watching their bottom line, this efficiency translates to real savings over the course of a project.

From digging precise utility trenches to creating intricate landscape features, from demolishing small structures to grading with pinpoint accuracy – these versatile machines do it all with remarkable stability. This versatility means you can tackle various aspects of your project without the hassle and expense of switching between multiple specialized machines.

Advantages of the 2 Ton Mini Excavator Class

The sweet spot of the 2 ton mini excavator class comes from balancing power with practicality. Their exceptional maneuverability stems from zero-tail or minimal-tail swing designs that allow complete rotation even in tight quarters. This means you can work between buildings or along fencelines without worrying about the counterweight swinging into obstacles.

Your customers will appreciate how these machines tread lightly. Weighing around 4,000-4,500 pounds, 2 ton mini excavators exert relatively low ground pressure compared to their bigger siblings. This means less damage to lawns, finished surfaces, or sensitive areas. You can even work on softer ground without creating a muddy mess of ruts and tracks.

Your accountant will love the fuel savings too. Typically consuming just 1-2 gallons per hour during normal operation, these compact diggers are significantly more economical than larger excavators. Over a machine’s lifetime, this efficiency adds up to substantial savings.

Transportation is refreshingly simple as well. With a combined weight (including trailer) typically under 7,000 pounds, a 2 ton mini excavator can be towed with a properly equipped pickup truck. No need for specialized transport equipment or commercial driver’s licenses in most states – just hook up and go.

For projects where minimizing disruption matters – like residential neighborhoods or environmentally sensitive areas – the compact footprint of these machines is invaluable. They get the job done with minimal impact on the surrounding environment.

Limitations & When to Step Up in Size

While I’m clearly a fan of what Takeuchi excavators, Hitachi compact excavators, and other manufacturers offer in this class, I should mention where these machines reach their limits.

When facing heavily compacted soil, rocky ground, or frozen earth, the bucket digging forces of 3,000-4,500 pounds might not be enough to power through efficiently. In these conditions, stepping up to a larger machine might save you time and frustration.

Reach limitations are another consideration. With maximum digging radius typically around 12-13 feet and digging depths of 7-9 feet, there are projects that simply require a bigger machine. If you’re excavating deeper foundations or reaching across wider obstacles, you might need to size up.

Moving large volumes of material can be less efficient with the smaller bucket capacity (typically 0.028-0.1 cubic meters) of a 2 ton mini excavator. More cycles mean more time, which could impact your project timeline.

When it comes to lifting heavier pipes, structures, or materials, these compact machines have their limitations. While adequate for many tasks, their lifting capacity simply can’t match larger models.

And while manufacturers of New Holland mini excavators, Link-Belt excavators and others have made tremendous strides in operator comfort, longer projects might be better served by larger machines with more spacious cabs and improved comfort features.

If your project involves deeper digging, handling heavier materials, or moving large volumes of earth, it might be time to consider a 3-5 ton class machine. At Kelbe Brothers Equipment, we’ll help you determine the perfect size for your specific needs based on our extensive experience with Wisconsin contractors just like you.

Top 2 Ton Mini Excavators Compared

The 2 ton mini excavator market is filled with excellent options that pack serious power into compact packages. At Kelbe Brothers Equipment, we’ve helped countless Wisconsin contractors find their perfect match from among the industry’s most trusted brands. Let’s take a closer look at some standout performers in this versatile equipment class:

Hitachi ZX20U-5 & Friends: 2 Ton Mini Excavator Highlights

When contractors ask me about reliability in the 2 ton mini excavator class, Hitachi Compact Excavators immediately come to mind. The ZX20U-5 showcases everything that makes Hitachi a trusted name on jobsites worldwide.

What makes this little powerhouse special? It starts with the robust Yanmar diesel engine delivering 14.5 horsepower – plenty of muscle for demanding applications. The zero-tail swing design is a game-changer when working between buildings or in tight backyard spaces. With a maximum digging depth of 7.7 feet, it handles most residential and light commercial excavation tasks with ease.

I especially appreciate the thoughtful operator station design, with excellent visibility that helps reduce fatigue during long workdays. The standard quick-coupler system and auxiliary hydraulics mean you’re ready for multiple attachments without expensive upgrades. When you’re switching between a bucket, auger, and hydraulic hammer throughout the day, this convenience pays for itself in productivity.

Maintenance couldn’t be simpler, with grouped service points that make daily checks a breeze. We’ve seen these machines deliver years of reliable service for our customers, with minimal downtime even in challenging Wisconsin conditions.

Takeuchi TB216 & TB225 Zero Swing Stars

Takeuchi excavators have earned their reputation through exceptional build quality and innovative features. As a proud Takeuchi dealer, we’ve seen how the TB216 and TB225 models consistently exceed customer expectations in the 2 ton mini excavator category.

The TB216 weighs in at just 3,900 pounds, making it incredibly easy to transport between jobsites. Its zero swing design steers tight spaces with confidence, while the 7.5-foot digging depth handles most residential projects efficiently. I love that Takeuchi offers both cab and canopy configurations – perfect for adapting to Wisconsin’s varied weather conditions.

For those needing a bit more reach, the TB225 steps up with an impressive 8.5-foot digging depth and increased bucket breakout force for tackling tougher materials. The ingenious retractable undercarriage is a feature my customers rave about – it narrows to squeeze through tight gates, then expands for rock-solid stability during operation.

Both models feature Takeuchi’s famously smooth pilot-operated controls that provide excellent feedback. This precision makes all the difference when digging around existing utilities or creating finished grades. The automatic fuel bleed system is another thoughtful touch that makes cold-weather starts much less frustrating – something our Wisconsin customers definitely appreciate!

Link-Belt 2 t X-Series Precision Diggers

As a Link-Belt dealer, I’ve watched contractors fall in love with these machines after just one demo. Link-Belt excavators in the 2-ton class combine innovative technology with rock-solid construction to deliver exceptional performance in challenging conditions.

The X-Series models feature fuel-efficient Yanmar diesel engines that strike the perfect balance between power and economy – a crucial consideration when fuel costs impact your bottom line. The advanced hydraulic system provides the smooth, responsive control that experienced operators demand, with short-throw pilot controls that reduce fatigue during long shifts.

What really sets these machines apart is their multi-function capability. The hydraulic system allows smooth combined movements – like swinging while extending the arm and curling the bucket – that translate to faster cycle times and greater productivity. When you’re bidding jobs competitively, this efficiency can make all the difference.

The undercarriage deserves special mention, with sealed track rollers and heavy-duty components designed to withstand Wisconsin’s varied terrain. Whether you’re working in sandy soils, clay, or rocky conditions, these machines deliver consistent performance and exceptional stability, even at maximum reach.

New Holland E20C Lineup for Contractors

As your local New Holland dealer, we’re proud to offer the E20C lineup of New Holland mini excavators that bring big-machine DNA to compact worksites. These machines incorporate the same engineering principles as their larger siblings in a right-sized package.

The E20C features a spirited 16.8 horsepower Yanmar diesel engine and zero house swing design that makes it perfect for urban renewal projects and tight residential work. The impressive 8.4-foot digging depth handles most foundation repairs and utility installations with ease.

One feature our customers particularly value is the auto-shift travel system, which intelligently adjusts between high and low speeds based on the load and terrain. This not only improves mobility around the jobsite but also reduces operator fatigue by eliminating manual shifting.

The expandable undercarriage provides the best of both worlds – narrow configuration for transportation and access, wider stance for stability during operation. Coupled with standard proportional auxiliary hydraulics, this machine is ready to tackle everything from precision grading to breaking concrete.

At Kelbe Brothers Equipment, we don’t just sell you a machine and disappear. Our experienced team helps you evaluate these options based on your specific applications, terrain challenges, and business needs. Whether you’re looking at excavators for sale or exploring excavators rental options, we’ll guide you to the 2 ton mini excavator that delivers the best value and performance for your unique situation.

Performance Specs & Attachment Flexibility

There’s something magical about the versatility of a 2 ton mini excavator. These nimble machines might be small in stature, but they pack a serious punch when it comes to getting work done. What makes them truly shine is their impressive performance combined with the ability to transform into almost any tool you need on the jobsite.

Digging Performance of a 2 Ton Mini Excavator

When our customers ask what these machines can really do, I love watching their eyes light up as I run through the capabilities. The bucket capacity of a 2 ton mini excavator typically ranges from 0.03 to 0.1 cubic meters – perfect for precision work without removing excessive material.

The breakout force is where these machines really impress, usually between 3,000 and 4,500 pounds. That’s enough muscle to tackle most residential and light commercial applications with ease. Even when working with tougher, compacted soils, these machines hold their own remarkably well.

Most models in this class offer digging depths between 7 and 9 feet, making them perfect for utility trenches, footings, and drainage work. With a digging radius of approximately 12 feet, you can cover a surprising amount of ground without constantly repositioning the machine.

What many first-time operators notice immediately is the responsiveness of the controls. Modern 2 ton mini excavators feature hydraulic systems that deliver impressive cycle times with smooth, precise movement. This translates directly into productivity – you’ll finish more work in less time while maintaining accuracy.

The ergonomics might not sound exciting on paper, but spend a full day in the operator’s seat and you’ll appreciate the thoughtful design. Comfortable seating positions, intuitive controls, and excellent visibility all contribute to reduced fatigue and better performance. We’ve had contractors tell us they can work longer days with less exhaustion thanks to these operator-focused features.

Choosing Attachments for Your 2 Ton Mini Excavator

This is where the 2 ton mini excavator truly becomes a Swiss Army knife for your jobsite. With the right attachments, one machine can handle dozens of specialized tasks.

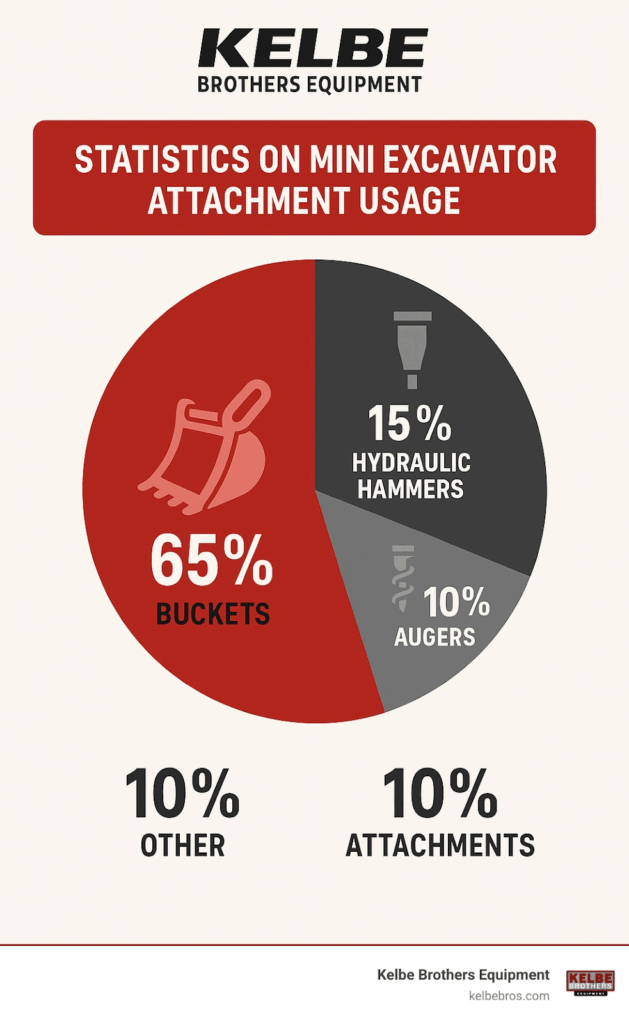

Buckets are the bread and butter, of course. From narrow trenching buckets for utility work to wider grading buckets for finishing, the right bucket makes all the difference. Most of our customers keep at least 2-3 different bucket sizes on hand to tackle various jobs.

A hydraulic thumb attachment transforms your excavator into a precise grabbing tool. Paired with your bucket, it creates a clamping action perfect for handling rocks, debris, logs, or demolition materials. I’ve watched contractors save hours of manual labor with this simple addition.

For drilling tasks, nothing beats an auger attachment. Whether you’re setting fence posts, planting trees, or installing signs, the right auger can drill clean, consistent holes in minutes. The auxiliary hydraulic flow on most 2 ton mini excavators (typically 8-12 gallons per minute) provides plenty of power for augers up to 12 inches in diameter.

Demolition work calls for a breaker attachment. While you won’t be tackling massive concrete structures with a 2-ton machine, these compact breakers make short work of sidewalks, small foundations, and similar obstacles.

For tough soil conditions, a ripper attachment can pre-loosen material before excavation, improving efficiency and reducing wear on your buckets. And don’t overlook the versatility of a grading blade for final site preparation and cleanup work.

The game-changer for many of our customers is investing in a quick-attach system. Being able to swap attachments in minutes rather than hours dramatically increases the machine’s versatility and your productivity. At Kelbe Brothers, we can help you select the right quick-attach system compatible with your specific model.

For more detailed information about attachment options and compatibility, check out our comprehensive Use and Care Manual. And remember, our parts service team is always available to help you find exactly what you need for your specific application.

Owning, Renting & Maintaining Your 2 Ton Mini Excavator

Let’s face it – whether you’re buying or renting a 2 ton mini excavator, you want to get the most bang for your buck. As someone who’s helped countless Wisconsin contractors find the perfect equipment solution, I’ve seen how proper care and smart decisions can make all the difference.

Operating Costs & Fuel Efficiency Tips for 2 Ton Machines

Your wallet will thank you for running your 2 ton mini excavator efficiently. These compact powerhouses typically sip diesel at a rate of 0.5-1.5 gallons per hour, depending on how hard you’re pushing them. Today’s models often include eco modes that can trim your fuel bill by 10-15% during lighter tasks.

One of the simplest ways to save fuel? Cut the idle time. I can’t tell you how many job sites I’ve visited where machines sit rumbling away during lunch breaks! Many newer models now feature auto-idle technology that automatically reduces engine RPM after a period of inactivity, then springs back to life when you touch the controls.

Maintenance planning isn’t just about checking boxes – it’s about protecting your investment. Keep your mini excavator running smoothly with these intervals:

- Daily quick-checks of fluid levels, track tension, and grease points

- Engine oil and filter changes every 250 hours

- Hydraulic filter replacement at 500 hours

- Fresh hydraulic oil at 1,000 hours

I always tell our customers that preventive maintenance pays for itself many times over. Pay special attention to track tension (too tight or too loose and you’re asking for trouble), grease points (those bushings aren’t cheap to replace), hydraulic connections (even small leaks waste power and can lead to bigger problems), and air filters (the engine’s lungs need to breathe!).

Don’t underestimate the value of operator training, either. A skilled operator not only gets more done but treats the machine with respect. At Kelbe Brothers, our service team can provide tips and training to help your operators work efficiently while extending component life.

2 Ton Mini Excavator Rental Checklist

Sometimes renting makes more sense than buying, especially for short-term projects. But before you load up that 2 ton mini excavator, take a few minutes for a proper inspection. Look for any visible damage or leaks, test all functions for smooth operation, check track condition and tension, verify attachment functions work properly, and confirm all safety features are operational.

Transport weight is a crucial consideration – most 2 ton mini excavators with their trailer will weigh under 7,000 pounds combined. Make sure your truck has the muscle to handle the load, your hitch class is adequate (typically Class III or higher), and your trailer has proper tie-down points and functioning brakes if required in your area.

Before the machine arrives at your job site, do yourself a favor and plan ahead. Map out access routes considering the machine’s width (typically about 3.6 feet), mark any underground utilities (trust me, you don’t want that surprise!), prepare a level area for loading/unloading, and think about how ground conditions might affect stability.

When it’s time to return your rental, a little courtesy goes a long way. Clean the machine thoroughly (avoiding those cleaning charges), refuel if your agreement requires it, snap a few photos to document conditions, and report any concerns to your rental provider.

At Kelbe Brothers Equipment, we take pride in our well-maintained excavators rental fleet. Our team provides thorough orientations for renters and ensures each machine is properly serviced between customers. With flexible daily, weekly, and monthly rates, we can accommodate projects of any duration.

As a fourth-generation family business serving Wisconsin contractors, we understand that downtime isn’t an option when you’re on a deadline. That’s why we offer 24/7 emergency support – because construction doesn’t always happen during business hours.

Need more information about our rental options? Visit our rental equipment page, learn about our service capabilities, or explore financing options if you’re considering ownership instead of rental.

Transport & Safety Checklist

Getting your 2 ton mini excavator safely to and from the jobsite is just as important as how you operate it once you’re there. Let’s walk through what you need to know to keep yourself, your crew, and your equipment safe.

When it comes to transport, think of your trailer as the foundation of safety. You’ll want one with a GVWR of at least 7,000 pounds, though I always recommend going with a 10,000-pound rated trailer to give yourself a comfortable safety margin. Wisconsin’s roads can be unpredictable, and that extra capacity provides peace of mind.

Your towing setup matters too. Make sure you’re using at least a Class III hitch with a 5,000-pound capacity, though a Class IV (10,000-pound) is even better. And don’t forget to verify that your truck or towing vehicle can actually handle the combined weight of both the excavator and trailer!

When loading your 2 ton mini excavator, proper ramp positioning is crucial. Too steep an angle creates a dangerous situation, especially in wet conditions. Once loaded, position the machine centered on the trailer for balanced weight distribution. This prevents swaying and improves handling on the road. Secure your excavator with at least four tie-downs attached to the designated points—never improvise here. Those chains or straps should have a minimum working load of 5,000 pounds each.

Safety doesn’t end when you reach the jobsite. Before firing up that engine each morning, take five minutes for a quick walk-around inspection. Check fluid levels, look for any overnight leaks, and verify track tension. These small checks can prevent big headaches later.

When operating your 2 ton mini excavator, always use the backfilling blade for additional stability during digging operations. This simple step dramatically improves both safety and productivity. And remember—always lower all attachments completely to the ground when stepping away from the machine, even for just a moment.

Your personal protection matters too. Hard hats, safety glasses, and hearing protection aren’t just suggestions—these machines typically generate 85-95 decibels during operation, which can cause hearing damage over time. High-visibility clothing ensures others on the jobsite can see you, while steel-toed boots protect your feet when handling attachments or during maintenance.

One of the most overlooked safety aspects is underground utility awareness. Always, always contact your local utility locating services before breaking ground. In Wisconsin, that means calling Diggers Hotline at 811 at least three business days before digging. When working near marked utilities, switch to hand-digging to prevent costly and potentially dangerous utility strikes. And keep an eye out for unmarked private utilities like irrigation lines or private electrical—they won’t show up on standard utility locates.

At Kelbe Brothers Equipment, we believe that safety isn’t just a checklist—it’s a mindset. That’s why we provide comprehensive safety orientations with every rental machine and offer additional safety training for your operators. Our team has decades of experience helping Wisconsin contractors safely transport and operate 2 ton mini excavators, ensuring you stay compliant with regulations while keeping your team safe. And remember, our 24/7 emergency support means we’re always just a phone call away if you need assistance.

Frequently Asked Questions about 2 Ton Mini Excavators

What is the typical digging depth and reach?

When contractors ask me about 2 ton mini excavators, digging capabilities are usually their first concern. These compact powerhouses typically offer maximum digging depths between 7-9 feet, which hits the sweet spot for most residential and light commercial applications.

What makes these machines particularly versatile is that some models come with extendable arms, giving you an extra 1-2 feet of depth when you need it. This can be a game-changer when you’re working on projects where specifications might change mid-job.

As for reach, you can expect a maximum digging radius of about 12-13 feet at ground level with most 2 ton mini excavators. Need to load material into a truck or clear obstacles? The typical dump height ranges from 8-10 feet, providing enough clearance for most small to medium dump trucks.

These specifications make perfect sense for Wisconsin contractors handling foundation repairs, utility trenching, or landscaping projects where you need decent digging capability but are working in areas where larger machines simply won’t fit.

Which attachments boost productivity in the 2 ton class?

I’ve seen how the right attachment can transform a 2 ton mini excavator from a simple digging machine into a versatile worksite powerhouse. Here are the game-changers I recommend to our customers:

The hydraulic thumb attachment is worth its weight in gold when you’re handling irregular materials. It works with your bucket to create a clamping action, making it dramatically easier to pick up rocks, tree stumps, or demolition debris. Many contractors tell me this attachment alone can reduce manual labor requirements by 30-40% on cleanup jobs.

Nothing boosts all-day productivity like a quick coupler system. While not technically an attachment itself, this system lets you swap between tools in minutes instead of hours. I’ve watched contractors transform their workflow by switching from a bucket to an auger to a breaker throughout the day without missing a beat.

For utility contractors, specialized trenching buckets in various widths (typically 12-24 inches for this class) can significantly speed up installation work. The right bucket width for your specific pipe or conduit size minimizes over-excavation and backfill requirements.

Need to install fence posts or plant trees? An auger attachment can drill precise holes in minutes, replacing hours of manual digging. I’ve seen landscapers complete an entire day’s worth of post holes before lunch with this setup.

For breaking up concrete or rock, a properly sized hydraulic breaker extends your machine’s capabilities dramatically. Just be sure your excavator’s hydraulic system can adequately power the attachment you choose – something our team at Kelbe Brothers Equipment can help you determine.

How do I tow a 2 ton mini excavator legally and safely?

Transporting your 2 ton mini excavator safely isn’t just about compliance – it’s about protecting your investment and ensuring everyone’s safety on the road. Here’s what you need to know:

From a legal standpoint, ensure your towing vehicle has adequate capacity for the combined weight, which typically runs around 7,000 pounds with the trailer included. Most states require trailer brakes for loads over 3,000 pounds, so your trailer should have properly functioning brake systems. Don’t forget proper lighting and reflectors – these are frequently checked during roadside inspections.

For safe transport, I always recommend using a trailer with a GVWR of at least 7,000 pounds, though 10,000 pounds gives you a better safety margin. Proper weight distribution is critical – position the excavator centered on the trailer with approximately 10-15% of the loaded trailer weight on the tongue.

Before hitting the road, lower the boom and arm with the bucket curled in to minimize height and prevent movement. Always use the designated tie-down points on both the excavator and trailer – these are engineered specifically for secure transport. We recommend using rated chains or straps with a minimum 5,000-pound working load at four points minimum.

One tip many operators forget: check your tie-downs after the first few miles and periodically during longer trips. Road vibration can loosen even well-secured loads.

At Kelbe Brothers Equipment, we’re happy to provide guidance on proper loading techniques when you rent or purchase a 2 ton mini excavator from us. And if you’d rather leave transport to the professionals, our delivery services cover the entire Wisconsin area with experienced drivers who know how to move these machines safely.

Conclusion

The 2 ton mini excavator truly represents that sweet spot between power and practicality that so many Wisconsin contractors are looking for. These mighty machines pack impressive digging capabilities into a frame that can steer the tightest urban job sites or residential backyards with ease.

Whether you’re eyeing a Hitachi ZX20U-5 with its reputation for reliability, one of Takeuchi’s impressive zero-swing models, a precision-engineered Link-Belt X-Series digger, or a versatile New Holland E20C from the renowned 200 Series lineup, the 2-ton class delivers exceptional value. Each manufacturer brings something special to the table, but they all share the core capabilities that make these machines indispensable on modern job sites.

At Kelbe Brothers Equipment, we’ve been helping Wisconsin contractors find the right equipment solutions for four generations. Our family-owned approach means we truly understand the challenges you face day in and day out on your projects. With convenient locations in Milwaukee, Madison, Green Bay, Butler, and De Pere, we’re never far away when you need us.

We don’t just sell or rent equipment – we build partnerships. Our team takes the time to understand your specific needs, helping you select the perfect 2 ton mini excavator for your unique applications. Whether you’re looking at new equipment purchases, flexible rental options for seasonal work, or smart financing solutions to help your business grow, we’ve got you covered.

Our factory-trained service technicians keep your machines running at peak performance, while our extensive parts inventory ensures quick resolution when maintenance needs arise. And because we know construction doesn’t always happen during business hours, our 24/7 emergency support means you’re never on your own when challenges arise.

The 2 ton mini excavator market offers excellent options for contractors and property owners alike, and Kelbe Brothers Equipment is your trusted guide through the selection process. Our commitment to quick turnaround, hassle-free service, and technical expertise has made us the preferred equipment partner for contractors throughout Wisconsin.

Ready to experience the Kelbe Brothers difference? Contact us today to learn more about our selection of 2 ton mini excavators from top manufacturers like Hitachi, Takeuchi, Link-Belt, and New Holland. Let us help you achieve those mini-machine, mega results on your next project!