Maximizing Productivity with Compact Track Loaders

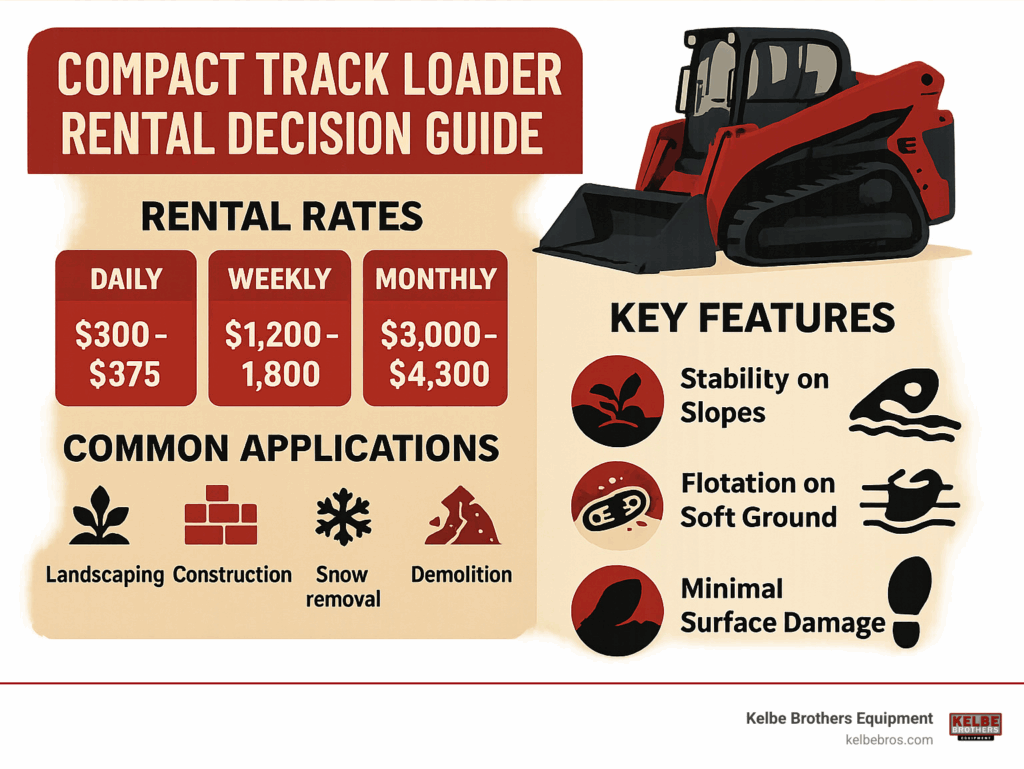

If you need to rent compact track loader equipment for your construction or landscaping project, here’s what you need to know about your options. Oftentimes, the following rate types, sizes, and delivery options are available:

- Daily rates for quick jobs

- Weekly rates depend on the size and capacity of the machines

- Monthly rates are best for long-term projects

- Common machine sizes are 1,600-2,200 lbs rated operating capacity (ROC)

- Delivery options: Most dealerships offer same-day or next-day delivery

Rent compact track loaders when you need superior stability on slopes, better flotation on soft ground, or want to minimize surface damage on finished landscapes. Unlike skid steers with wheels, compact track loaders distribute weight more evenly (typically under 5 psi ground pressure) and won’t get stuck in mud or soft soil conditions.

When deciding whether to rent, consider that compact track loaders excel in a wide range of applications – from landscaping and construction to snow removal and demolition. They’re the perfect solution when you need versatile equipment without the long-term commitment of ownership.

I’m Jeffrey J. Miller, President of Kelbe Brothers Equipment, where I’ve overseen countless rent compact track loader transactions and helped contractors select the right machines for their specific project needs. My experience has shown that the right rental equipment can make the difference between project delays and smooth, on-time completion.

What Is a Compact Track Loader?

A compact track loader (CTL) is a versatile piece of construction equipment that combines the maneuverability of a skid steer with the stability and traction of a tracked undercarriage. These powerful machines feature rubber tracks instead of wheels, allowing them to distribute weight more evenly across the ground surface.

The core of a compact track loader is its crawler undercarriage system, which consists of rubber tracks mounted on rollers and drive sprockets. This design provides several key advantages:

- Lower ground pressure (typically 4-5 psi compared to 30+ psi for wheeled machines)

- Superior stability on uneven terrain and slopes

- Better traction in mud, sand, and loose soil

- Reduced ground disturbance on finished surfaces

- Higher pushing power and breakout force

At Kelbe Brothers Equipment, we’ve seen Wisconsin contractors increasingly turn to compact track loaders for their versatility across our state’s varied terrain and weather conditions. From muddy spring construction sites to snow-covered winter projects, these machines keep work moving forward when wheeled equipment might struggle.

Tracks vs. Wheels: Core Differences

When you rent compact track loader equipment instead of a wheeled skid steer, you’re choosing a machine with fundamental operational differences that can significantly impact your project:

Traction: Tracked machines provide superior grip on virtually any surface. The extended ground contact area means more of the machine’s power transfers to the ground, resulting in better pushing force and less slippage, especially in wet or loose conditions.

Flotation: This refers to the machine’s ability to “float” over soft surfaces rather than sink. With their weight distributed across a larger footprint, compact track loaders can work effectively on soft ground where wheeled machines would get stuck.

Site Access: Tracks allow access to areas that might be impossible for wheeled machines, such as steep slopes, muddy sites, or sandy terrain. This expanded accessibility can eliminate the need for extensive temporary roads or ground preparation.

Minimal Turf Damage: For landscaping projects or work on finished surfaces, tracks significantly reduce the risk of rutting or tearing up the ground. This can save substantial restoration costs when working on established lawns or completed site work.

Compact Track Loader vs. Skid Steer Loader

While compact track loaders and skid steer loaders share many similarities in terms of attachments and basic functionality, their performance characteristics differ in several important ways:

Turning Radius: Both machines use skid steering (pivoting by having the wheels or tracks on one side move at a different speed than those on the other), but track loaders typically have a slightly larger turning radius due to their track design.

Stability: Compact track loaders offer superior stability, especially when lifting or operating on slopes. Their lower center of gravity and wider track stance provide a more stable platform for lifting operations.

Lift Geometry: Both machine types are available with either radial lift (ideal for digging and grading) or vertical lift (better for loading and material handling) configurations. The choice depends more on your specific application than on whether the machine has tracks or wheels.

Rated Operating Capacity: Track loaders typically offer higher rated operating capacities than similarly sized skid steers because of their improved stability. This means you can often lift and move heavier materials with a track loader of comparable size.

At our Wisconsin locations in Milwaukee, Madison, Green Bay, Butler, and De Pere, we’ve found that many contractors who rent compact track loader equipment do so specifically for challenging ground conditions that would limit a wheeled machine’s effectiveness.

Why Rent a Compact Track Loader Instead of Buying

Let’s face it – heavy equipment isn’t cheap. When you’re eyeing that shiny new compact track loader, the question isn’t just “Can I afford it?” but “Should I own it?” As someone who’s helped countless Wisconsin contractors make this decision, I can tell you that renting often makes more dollars and sense.

Capital preservation is probably the biggest advantage. Instead of tying up $50,000-$100,000+ in a single machine, you can keep that cash flowing through your business where it might be needed most. Think about it – that’s money that could be covering payroll, bidding on new jobs, or handling unexpected expenses.

When you rent compact track loader equipment, you gain incredible fleet flexibility, too. Monday’s landscaping job might need a nimble Takeuchi compact track loader with a bucket attachment, while Friday’s excavation project calls for a larger New Holland 200 Series with greater lifting capacity. Renting lets you match the exact machine to each specific job.

The storage headaches that come with ownership? Gone. No need to worry about where you’ll park that loader during the off-season or between jobs. No security concerns about expensive equipment sitting vulnerable in your yard. Just return it when you’re done and it’s off your mind.

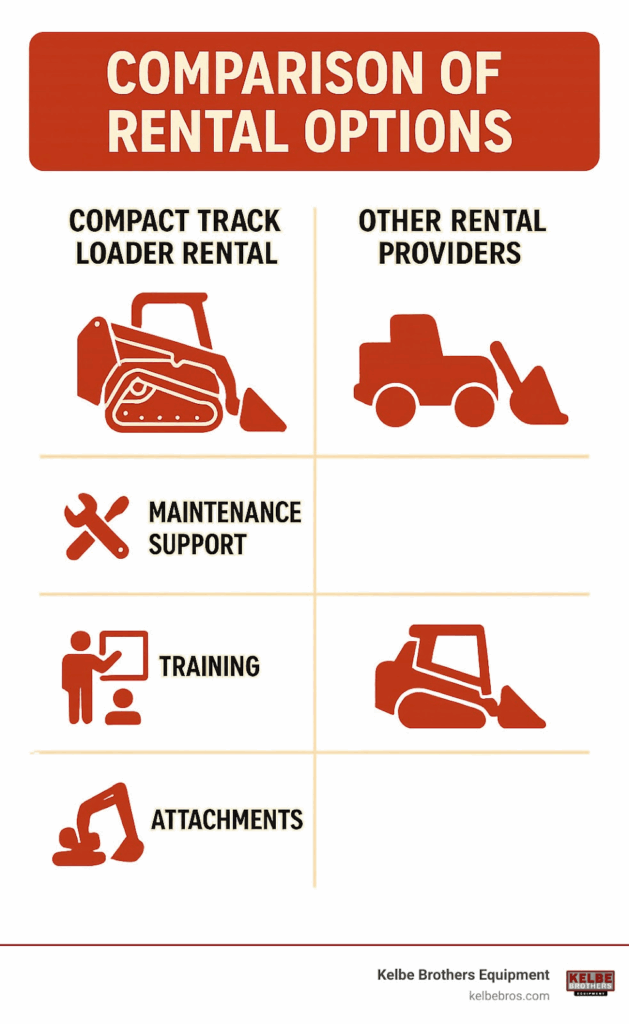

Here’s something many contractors don’t fully consider until they’ve owned equipment for a while: maintenance is included with rentals. At Kelbe Brothers, we handle all the regular service, repairs, and unexpected breakdowns. That means no surprise repair bills and no downtime waiting for parts to arrive.

Wisconsin’s weather doesn’t exactly cooperate year-round, does it? Our seasonal work patterns make ownership particularly challenging. Why pay for equipment that sits idle during slow months? Renting aligns your equipment costs directly with your revenue-generating periods.

Want to learn more about transitioning from renting to ownership eventually? Check out our used equipment options when you’re ready to take that step.

When to Rent a Compact Track Loader for Short-Term Projects

Some situations practically scream “rental” – like when you suddenly land a new contract that requires more equipment than you currently have. Instead of scrambling to purchase, you can have a Link-Belt or Hitachi machine delivered to your site within 24 hours.

Specialized attachments are another perfect rental scenario. That forestry mulcher you need for just one land-clearing job? Rent it along with a compatible loader rather than investing thousands in an attachment you’ll rarely use.

Wisconsin snow events create unpredictable equipment demands. Renting additional compact track loaders during major snowfalls lets you meet service commitments without maintaining a larger year-round fleet. Our New Holland 200 Series machines with snow attachments are particularly popular during winter months.

When your regular work involves firm surfaces but you occasionally tackle projects with challenging ground conditions – soft soil, steep slopes, or finished landscapes – renting a track loader for just those specific projects makes perfect financial sense.

Long-Term Rentals & Rent-to-Own Path

For extended projects, our long-term options provide even more flexibility. Predictable monthly expenses make budgeting a breeze, with significant discounts compared to daily or weekly rates. This helps smooth out your cash flow while keeping your equipment costs directly tied to active projects.

Many contractors use our rentals as an extended test drive. There’s no better way to know if a Takeuchi or New Holland loader truly fits your operation than using it on your actual job sites for several weeks. It’s like dating before marriage – smart move!

Our popular rent-to-own programs let a portion of your rental payments apply toward purchase if you decide to buy. This creates a practical pathway to ownership that spreads the financial impact over time while you’re actually using the equipment to generate revenue.

We structure our long-term agreements with reasonable hour limits – typically 8 hours daily, 40 hours weekly, and 176 hours per 4-week period. This gives you plenty of operational time while maintaining the equipment’s value.

Perhaps most importantly, rent-to-own means building residual value rather than just paying for usage. When the rental period ends, you’ve got equity in a machine you know inside and out, rather than starting from zero.

As a fourth-generation, family-owned company serving Wisconsin contractors since 1926, we’ve designed our rental programs based on what actually works for local businesses. We understand the challenges you face because we’ve been helping contractors overcome them for nearly a century.

Choosing the Right Compact Track Loader Rental: Size, Capacity & Attachments

Finding that perfect compact track loader for your project doesn’t have to feel overwhelming. When I talk with contractors at our Kelbe Brothers Equipment locations across Wisconsin, I always start by understanding what they’ll be moving, where they’ll be working, and how long they’ll need the machine.

Our fleet features reliable New Holland CTL 200 Series and Takeuchi Compact Track Loaders that have proven themselves on countless Wisconsin jobsites. But which one is right for your specific needs? Let’s break it down:

Rated Operating Capacity (ROC) is really your starting point when you rent compact track loader equipment. Think of it as the machine’s muscle – how much weight it can safely lift and carry:

- Small (300-600 lb ROC): These nimble machines are perfect for squeezing through those standard 36″ backyard gates on residential landscaping jobs. They’re your best friend in tight spaces where bigger machines simply won’t fit.

- Medium (1,600-2,200 lb ROC): This is our most frequently rented size, and for good reason. These versatile workhorses handle everything from general construction to landscaping and material handling with confidence.

- Large (3,400+ lb ROC): When you’re moving heavy materials on commercial construction sites or tackling serious excavation work, these powerful machines deliver the performance you need without compromise.

The hydraulic system is another crucial consideration. Standard flow systems (typically 15-25 GPM) work beautifully for everyday attachments like buckets and forks. But if you’re planning to run high-demand attachments like mulchers or snow blowers, you’ll want a high-flow system (30-45 GPM) that delivers the extra power these hungry attachments require.

Your lifting needs also determine whether you’ll want radial lift or vertical lift geometry. Our New Holland 200 Series loaders feature vertical lift designs that excel when loading trucks or stacking materials high, providing maximum forward reach at full height. Our Takeuchi models offer both lift patterns, including radial lift options that give you better digging performance and mid-height reach.

Attachment Arsenal That Multiplies Productivity

The true magic of compact track loaders lies in their versatility. With the right attachments, one machine transforms into a dozen specialized tools. At Kelbe Brothers, we’ve built an impressive attachment inventory to boost your productivity:

Need to move different materials? Our bucket selection ranges from standard dirt buckets to specialized 4-in-1 buckets that grab, scoop, grade, and dump. For bulky or irregular materials, our grapples provide the secure grip you need for brush clearing or debris handling.

Planning to install fencing or plant trees? Our augers with various bit sizes drill perfect holes in minutes, saving your crew hours of backbreaking work. Need to run utilities? Our trenchers create precise ditches for irrigation, drainage, or electrical lines without renting a separate machine.

When cleanup time arrives, our angle and pickup brooms make short work of jobsite debris or light snow removal. And thanks to hydraulic quick-couplers, your operators can swap these attachments in minutes without leaving the cab, keeping your project moving forward without frustrating delays.

Want to learn more about our parts and attachment options? Visit our parts and attachments page for complete details.

Match Machine to Jobsite Conditions

The right machine for your project depends heavily on where you’ll be working. When you rent compact track loader equipment from us, we’ll help you evaluate several key factors:

Access limitations can make or break your equipment choice. I’ve seen too many projects delayed when contractors find their machine won’t fit through an entry point. Our smallest track loaders steer standard 36″ backyard gates with ease, while larger models require wider access. Always measure twice before selecting your machine!

Material density significantly impacts your required capacity. Moving lightweight mulch or topsoil? You can often get by with a smaller machine. Handling dense gravel, concrete debris, or heavy construction materials? You’ll need a loader with appropriate capacity to avoid multiple trips and operator frustration.

Terrain challenges matter too. While all track loaders handle slopes better than wheeled machines, steeper grades require models with lower centers of gravity and wider, more stable track designs. Our Takeuchi and New Holland track loaders excel on Wisconsin’s varied terrain, from muddy construction sites to hilly residential properties.

Visibility requirements shouldn’t be overlooked, especially in confined spaces or busy jobsites with multiple workers. Cab design, window placement, and overall machine dimensions all affect operator sightlines and safety.

At Kelbe Brothers Equipment, our rental specialists don’t just hand you keys – we help you evaluate these factors to ensure you get exactly the right machine for your specific conditions. Our decades of experience serving Wisconsin contractors means we understand local job conditions and can recommend the perfect machine for your unique challenges.

Rental Process, Transport, Maintenance & Safety

Renting a compact track loader from Kelbe Brothers Equipment is a straightforward process designed to get you up and running quickly. Here’s what to expect:

- Online Reservation: Browse our available equipment on our website or call any of our Wisconsin locations to discuss your needs.

- Insurance Certificate: Provide a certificate of insurance naming Kelbe Brothers Equipment as the additional insured. This protects both parties during the rental period.

- Delivery Scheduling: We offer delivery throughout Wisconsin, typically with same-day or next-day service depending on your location.

- Equipment Orientation: Upon delivery, our team provides a basic orientation to the machine’s features, controls, and safety systems.

When transporting a compact track loader yourself, proper securing is essential:

Tie-Down Points: Use designated tie-down points on the machine, not on the ROPS (Roll-Over Protective Structure) or other components not designed for securing loads.

Weight Distribution: Position the loader centered on the trailer with the heaviest part (typically the engine) toward the front.

Chain Rating: Ensure chains or straps meet or exceed the weight rating required for the machine (typically 4 chains rated for at least 1/3 of the machine’s weight each).

Operator Training & Certification Requirements

Safe operation of compact track loaders requires proper training and adherence to safety protocols:

Walk-Around Inspection: Before operation, conduct a thorough inspection checking for leaks, track damage, attachment connections, and safety system functionality.

Seat-Belt Use: Always use the seat belt and lower the restraint bar when operating. These are critical safety features that prevent ejection during rollovers.

ROPS/FOPS: Never modify the Roll-Over Protective Structure or Falling Object Protective Structure, as these are essential safety systems.

Backup Alarms: Ensure backup alarms are functional and use a spotter when visibility is limited.

ANSI/OSHA Basics: While no specific license is required to operate a compact track loader, operators should be familiar with ANSI and OSHA guidelines for safe operation.

At Kelbe Brothers, we can provide basic operational training when you rent compact track loader equipment, but we recommend formal training for operators who will use the equipment regularly.

Maintenance Support During Rental

When you rent from Kelbe Brothers Equipment, you benefit from our comprehensive maintenance support:

Fluid Checks: We provide guidance on daily fluid checks to ensure proper operation.

Track Tension: Proper track tension is crucial for performance and track longevity. Our delivery personnel can demonstrate how to check and adjust tension if needed.

Greasing Intervals: Critical pivot points require regular greasing. We’ll show you which points need attention and how often.

Rapid-Response Field Service: If any issues arise during your rental period, our 24/7 emergency support team can quickly respond to your jobsite anywhere in Wisconsin. As a family-owned business with deep roots in the construction industry, we understand that downtime costs you money.

All maintenance beyond daily checks is our responsibility, giving you peace of mind and eliminating unexpected repair costs during your rental period.

Comparing Rental Providers & Rent-to-Own Options

When you’re ready to rent compact track loader equipment in Wisconsin, not all providers offer the same experience. At Kelbe Brothers Equipment, we take pride in our fourth-generation, family-owned approach that brings something special to the table.

Our deep industry connections with manufacturers like New Holland and Takeuchi mean we can offer you the latest equipment models when others might have waiting lists. There’s a real difference when you work with an authorized dealer – our technicians receive factory training, we stock genuine parts, and we understand these machines inside and out in ways generic rental outlets simply can’t match.

“I’ve been helping contractors find the right equipment for over 15 years,” says our rental manager. “When someone needs to rent compact track loader equipment, we don’t just hand them keys – we take time to understand their project and recommend the perfect match.”

Our attachment selection is another area where we shine. We’ve carefully built an inventory of buckets, augers, trenchers and specialty tools that are perfectly matched to our New Holland and Takeuchi track loaders. This compatibility ensures you’ll get maximum performance without the frustration of hydraulic flow mismatches or connection problems.

Evaluating Reputation and Fleet Quality

Before signing any rental agreement, take a moment to do some homework that could save you headaches down the road:

Start with customer reviews – what are others saying about their rental experiences? We’re proud of our track record and encourage potential customers to check what Wisconsin contractors have to say about their experiences with us.

Equipment age matters tremendously. Our fleet includes the latest New Holland 200 Series compact track loaders and Takeuchi models because newer machines simply give you better reliability, improved fuel efficiency, and operator-friendly features that older units can’t match.

We’re completely transparent about maintenance records, too. Every machine in our rental fleet has a detailed service history that we’re happy to share. This level of openness demonstrates our commitment to sending you home with equipment that won’t let you down mid-project.

Our flexible rental terms are designed around real-world project needs. Whether you need a machine for a quick weekend landscaping job or a months-long commercial construction project, we’ve structured our daily, weekly, and monthly rates to give you the best value for your timeline.

With our five Wisconsin locations in Milwaukee, Madison, Green Bay, Butler, and De Pere, on-time delivery is never an issue. We understand that your crews and other equipment might be standing by waiting for that track loader to arrive – we won’t keep you waiting.

How to Benchmark Offers Before You Rent a Compact Track Loader

Smart contractors know how to compare rental options beyond just the daily rate. Here’s how to ensure you’re getting true value when you rent compact track loader equipment:

Pay attention to brand availability. We specifically chose to carry premium New Holland and Takeuchi compact track loaders because they consistently outperform other options in reliability and performance. The difference becomes clear when you’re working in challenging Wisconsin conditions.

Ask direct questions about support turnaround times. What happens if your machine has an issue at 7 AM on a Saturday? Our 24/7 emergency support team is always ready to minimize your downtime with rapid response across Wisconsin.

Take time to understand contract clarity before signing. Our agreements clearly spell out hour limits, damage policies, and return conditions in plain language. We believe transparency builds trust – you’ll never face surprise charges or hidden fees when working with Kelbe Brothers.

“We’re not just in the equipment business; we’re in the relationship business,” explains our president. “Many of our customers have been renting from us for decades because they know we stand behind our equipment and our word.”

For the best experience when you need to rent compact track loader equipment in Wisconsin, visit our rental equipment page or stop by any of our locations to see why contractors have trusted Kelbe Brothers for generations. For the latest industry research on equipment rental trends, check out the American Rental Association website.

Frequently Asked Questions about Compact Track Loader Rentals

Do I need a CDL to haul a compact track loader?

Good news for most contractors – you probably don’t need a Commercial Driver’s License to transport your rented loader. The combined weight of a typical compact track loader and trailer usually stays well below Wisconsin’s 26,001-pound CDL threshold.

For perspective, most medium-sized compact track loaders weigh between 7,500-8,500 pounds, with a suitable trailer adding another 2,000-3,000 pounds. Just make sure your truck has the appropriate towing capacity for this combined weight.

Not comfortable hauling equipment yourself? No problem! At Kelbe Brothers, we’re happy to deliver directly to your jobsite. Our delivery service covers the entire state from our convenient Wisconsin locations in Milwaukee, Madison, Green Bay, Butler, and De Pere.

What ROC should I choose for landscaping vs. earthmoving?

Choosing the right Rated Operating Capacity (ROC) makes all the difference in your productivity. For typical backyard changes and residential landscaping, a compact track loader with 1,600-2,000 lb ROC hits the sweet spot. These versatile machines handle everything from precision grading to material spreading while still navigating those tight residential spaces with ease.

For serious earthmoving and construction work, I’d recommend stepping up to a machine with 2,200-3,400+ lb ROC. These powerhouses give you the stability and muscle needed for excavation, moving heavy materials, and aggressive grading work.

Our New Holland 200 Series compact track loaders offer options across this entire range, so we can match you with the perfect machine for your specific project needs. Whether you’re creating a backyard paradise or preparing a commercial building site, we’ve got you covered.

Can I swap attachments mid-rental without extra paperwork?

We understand that projects evolve and needs change! When you rent compact track loader equipment from Kelbe Brothers, switching attachments mid-project is refreshingly simple. Just give your rental representative a call when you realize you need something different.

In most cases, we’ll handle the swap with minimal paperwork—typically just a quick addition to your existing rental agreement. We pride ourselves on same-day attachment delivery to your jobsite whenever possible, keeping your project moving forward without frustrating delays.

This flexibility is part of what makes working with a family-owned business like ours different. We’re not buried in corporate red tape, so we can adapt quickly to your changing needs. After four generations in Wisconsin’s construction industry, we’ve learned that being responsive to our customers’ needs isn’t just good service—it’s good business.

Conclusion

When you rent compact track loader equipment from Kelbe Brothers Equipment, you’re not just getting a machine—you’re gaining a trusted partner who’s invested in your success. Think of us as the backstage crew making sure your project hits every mark without a hitch.

Our carefully curated selection of New Holland 200 Series and Takeuchi compact track loaders brings Wisconsin contractors the perfect blend of power, versatility and reliability. Whether you’re navigating the muddy spring conditions in Milwaukee or tackling frozen ground in Green Bay, our machines keep your project moving forward when others might be stuck spinning their wheels.

As a fourth-generation, family-owned business with deep Wisconsin roots, we understand what keeps contractors up at night—deadlines, budgets, and equipment that needs to perform day in and day out. That’s why we’ve built our rental program around your real-world needs:

We offer truly flexible rental terms that align with your project timeline, not rigid packages that force you to pay for days you don’t need. Our multiple locations across Wisconsin mean we can typically deliver your equipment the same day you call. And when something unexpected happens (because it always does), our 24/7 emergency support team jumps into action to keep your downtime to an absolute minimum.

The versatility of our Hitachi, Link-Belt, New Holland, and Takeuchi units, paired with our extensive attachment inventory, means one rental can often handle tasks that would otherwise require multiple specialized machines. This multipurpose approach doesn’t just save you money—it simplifies logistics and reduces the learning curve for your operators.

I’ve personally seen how the right equipment at the right time can transform a challenging project into a smooth operation. That’s why everyone at Kelbe Brothers—from our service technicians to our rental coordinators—is committed to being the partner you can count on when the pressure’s on.

Ready to keep your next project rolling without a hitch? Explore our rental equipment options or give us a call today. Experience why Wisconsin contractors have trusted our family’s expertise and dedication for generations.