A forestry mulcher for skid steer is a hydraulic attachment that transforms your compact loader into a powerful land-clearing machine, grinding trees, brush, and stumps into mulch in a single pass—no cutting, piling, or hauling required.

What You Need to Know About Forestry Mulchers for Skid Steers:

- What it does: Attaches to skid steers and compact track loaders to shred vegetation up to 8-14 inches in diameter into mulch

- Two main types: Drum mulchers (fine, uniform finish) and disc mulchers (high-speed cutting power)

- Power requirements: Standard flow (16-30 GPM) or high flow (32-50 GPM) hydraulic systems; typically 40-135 HP

- Key applications: Forestry management, right-of-way maintenance, site preparation, firebreaks, invasive species control

- Major advantage: Single-machine operation eliminates the need for cutting, piling, hauling, and burning

These attachments turn dense vegetation into a protective layer of mulch that enriches soil and controls erosion, eliminating debris removal. For clearing construction sites, maintaining power lines, or reclaiming farmland, a forestry mulcher dramatically reduces project time compared to traditional methods.

Modern technology includes variable torque motors that prevent stalling and bite-limiter systems for efficient cutting. Drum mulchers shred material up to 8 inches in diameter for a fine finish, while disc mulchers handle material up to 14 inches for high-production clearing.

Choosing the right mulcher depends on your carrier’s hydraulics, the material, and desired finish. A high-flow New Holland 200 Series compact track loader can power a professional-grade mulcher for clearing several acres per day, while standard-flow machines are suited for lighter tasks.

I’m Jeffrey J. Miller, President of Kelbe Brothers Equipment. I’ve seen how the right forestry mulcher for skid steer transforms efficiency for contractors across Wisconsin. We help operators match the right attachment to their machines and applications to ensure maximum productivity.

WHAT IS A SKID STEER FORESTRY MULCHER AND WHAT DOES IT DO?

A forestry mulcher for skid steer is a powerful hydraulic attachment that turns your compact track loader into a vegetation-shredding machine. Connected to a New Holland or Takeuchi Compact Track Loader, it uses mechanical teeth to efficiently clear brush, trees, and stumps.

The skid steer’s hydraulic system powers the mulcher, spinning a rotor (drum or disc) covered in steel or carbide-tipped teeth at high speeds. These teeth shred and pulverize vegetation into a fine, biodegradable mulch.

This one-pass solution for land clearing is simple and fast. As you drive forward, the mulcher leaves a uniform bed of organic mulch that prevents erosion, retains moisture, and improves soil health as it decomposes, eliminating the need for debris removal.

The forestry mulcher is ideal for site preparation, right-of-way maintenance, creating firebreaks, and clearing trails. To learn more about how New Holland and Takeuchi compact equipment can improve your operations, see our guide on unpacking the power of compact equipment.

PRIMARY APPLICATIONS

A forestry mulcher for skid steer is a versatile attachment used by Wisconsin contractors for forestry management (clearing undergrowth, thinning forests) and farmland reclamation (turning overgrown pastures into productive land).

Invasive species control is another key application. The mulcher effectively grinds down aggressive plants like buckthorn and honeysuckle, preventing regrowth more effectively than cutting.

Mulchers are also essential for utility line and right-of-way maintenance, keeping corridors clear for safety and reliability. In commercial and residential development, they quickly prepare sites by clearing vegetation and leaving a surface ready for construction.

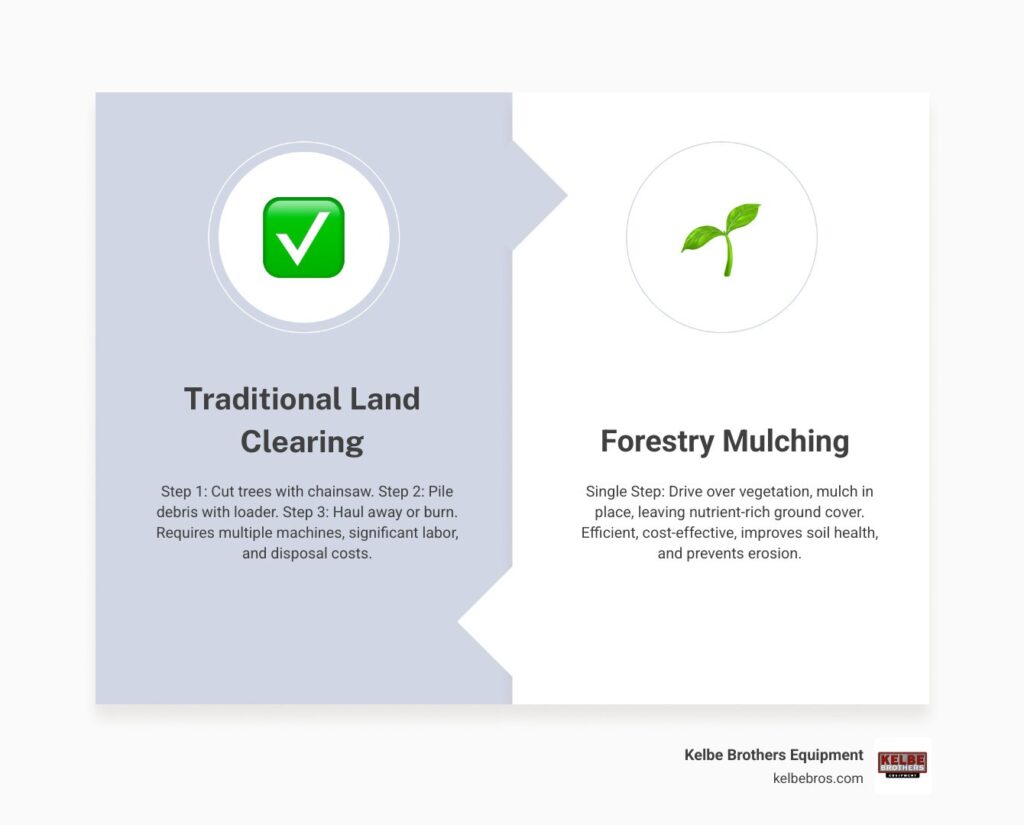

ADVANTAGES OVER TRADITIONAL CLEARING METHODS

Unlike traditional methods requiring a crew, chainsaws, and multiple machines, a forestry mulcher for skid steer streamlines the process into a single-machine operation. One operator with a New Holland 200 Series Compact Track Loader and a mulcher can do the work of an entire crew.

Eliminating haul-off and burning saves significant time. Vegetation is processed on-site into useful mulch, avoiding dump fees, hauling, and burn permits.

The soil health benefits are significant. The organic mulch layer decomposes, returning nutrients to the soil, acting as a natural fertilizer, and retaining moisture to reduce water runoff.

For erosion control, the mulch acts as a protective blanket against wind and water, which is vital on slopes. Mulchers operate with low ground disturbance, preserving topsoil and the root systems of desirable trees, unlike bulldozers.

From a wildfire prevention standpoint, mulchers excel at fuel reduction. They convert dense undergrowth into fine mulch that lies flat, reducing combustible material. The US Forest Service has documented the benefits of mulching for fuel reduction in creating safer landscapes.

DRUM VS. DISC: CHOOSING THE RIGHT MULCHER HEAD

When adding a forestry mulcher for skid steer to your fleet, the first major decision is choosing between a drum or disc mulcher head. Each has unique strengths, and understanding them is key to selecting the right attachment for your needs.

Here’s a quick look at how they stack up:

| Feature | Drum Mulchers | Disc Mulchers |

| Mulch Size | Finer, more uniform | Coarser, less uniform |

| Cutting Speed | Moderate to fast | Very fast, high production |

| Below-Grade Ability | Excellent (can grind stumps and roots below grade) | Limited (primarily cuts at or above ground level) |

| Ideal Application | Aesthetic finishing, stump grinding, utility lines, firebreaks, residential clearing | Large-scale land clearing, felling larger trees, high-volume brush removal, and commercial sites |

DRUM MULCHERS: THE FINE-FINISH SPECIALISTS

A drum mulcher uses a horizontal, cylindrical rotor covered with teeth. As it spins, it pulls in and grinds vegetation into a consistently fine, uniform mulch.

Drum mulchers excel at producing a neat finish and are ideal for grinding stumps and roots below ground. They throw less debris, making them safer for work near residential areas. Wisconsin contractors often use them with a New Holland compact track loader for clearing utility lines, creating firebreaks, and residential projects. They can pulverize trees up to 8 inches in diameter, leaving a clean layer of mulch.

DISC MULCHERS: THE HIGH-PRODUCTION POWERHOUSES

A disc mulcher features a large, vertical spinning disc with cutting teeth on its perimeter. It uses a “flywheel effect” to build energy, allowing it to cut and fell larger trees with incredible speed.

Disc mulchers are the top choice for high-production clearing. They are most efficient for rapidly clearing dense areas and felling trees up to 14 inches thick, making them ideal for large-scale commercial sites. Although they produce a coarser mulch and are not designed for below-ground work, their speed is best. Modern disc mulchers also feature quick recovery times after cutting through heavy material.

KEY FEATURES THAT DEFINE PERFORMANCE

Beyond the drum vs. disc choice, the performance of a forestry mulcher for skid steer depends on key engineering details: the cutting teeth, hydraulic systems, and control technology. As Wisconsin’s experts in equipment attachments, we know these features are critical for productivity.

CUTTING TEETH: THE HEART OF THE HEAD

The teeth on a mulcher head are the most critical component for performance. Choosing the right style for your job conditions is essential for efficiency and will save you time and frustration.

Carbide teeth are the durable workhorses for mulching. With a carbide tip on a steel body, they are built for abuse, making them ideal for rocky Wisconsin terrain and stump grinding. They resist wear and last three to five times longer than steel teeth in harsh conditions, maximizing uptime.

Steel or knife teeth are designed to slice wood, producing a finer mulch and working faster in softer conditions. They are sharper and more aggressive but require more frequent sharpening or rotation, especially with ground contact. Some designs offer better durability against occasional rock impacts.

The shape and placement of teeth are also critical. Many modern mulchers use bite-limiter technology, where the tooth geometry controls cutting depth. This prevents the rotor from bogging down, ensuring consistent productivity.

Modern mulcher designs emphasize easy replaceability and maintenance. Quality attachments allow for quick rotation or replacement of individual teeth, minimizing downtime. Some even allow for mixed tooth styles on the same rotor for customized performance.

ADVANCED DRIVE AND HYDRAULIC SYSTEMS

While teeth are important, the hydraulic and drive systems are what define a professional-grade forestry mulcher for skid steer. Modern systems are highly sophisticated and prevent frustrating stalls.

Variable torque motors are a key innovation. These load-sensing hydraulic motors automatically adjust to resistance, providing more torque for thick material to prevent stalls and increasing speed for lighter material. This smart system can boost productivity by up to 30% while reducing hydraulic temperature and fuel use on your New Holland compact track loader.

Advanced automatic power adjustment systems continuously calibrate the mulcher to your carrier machine in real-time. This optimizes performance with your specific skid steer or compact track loader, minimizing stalling and shortening recovery time for consistent operation.

The combination of bite-limiter teeth and variable torque motors creates a highly efficient system. The teeth regulate material intake while the motor adjusts power to the load, maximizing uptime in challenging conditions.

The drive system design (direct or belt drive) also affects performance. Direct drive offers maximum power transfer. Belt drives, common on disc mulchers, can provide faster spool-up and recovery times, as the belts absorb shock and help reduce stress on the hydraulic system.

MATCHING THE MULCHER TO YOUR MACHINE: A GUIDE FOR THE FORESTRY MULCHER FOR SKID STEER

Choosing the right forestry mulcher for skid steer goes beyond drum vs. disc; it’s about creating a safe and powerful partnership between the attachment and your carrier. A poor match leads to inefficiency and damage. At Kelbe Brothers Equipment, we stress the importance of a full compatibility check and proper machine upgrades.

Your New Holland or Takeuchi machine must work in harmony with the mulcher. A proper match ensures maximum productivity and reliability, preventing problems that could have been avoided with the right setup.

SKID STEER POWER AND HYDRAULIC REQUIREMENTS

Hydraulic power is the lifeblood of your mulcher. Without adequate flow and pressure, performance suffers. The most critical specification is the hydraulic flow rate, measured in Gallons Per Minute (GPM).

Mulchers are categorized as Standard Flow (16-30 GPM) for lighter brush and maintenance, or High Flow (32-50+ GPM) for serious land clearing. High-flow models handle larger material much faster.

Operating pressure (PSI) is also a factor, but most modern New Holland and Takeuchi loaders provide adequate pressure. Flow rate is the most common compatibility issue.

Your machine’s engine horsepower (HP) determines its hydraulic power. Mulchers are rated for specific HP ranges (e.g., 40-135 HP), which dictates the size of material they can handle. Matching the mulcher’s HP requirement to your carrier is essential for performance and longevity.

Also consider the machine operating weight. Your loader needs the stability and lift capacity to handle the heavy attachment safely, especially on uneven ground. As a New Holland dealer in Wisconsin, we ensure your equipment is perfectly matched.

ESSENTIAL CARRIER UPGRADES FOR A FORESTRY MULCHER FOR SKID STEER

Once you confirm hydraulic compatibility for a forestry mulcher for skid steer, you must consider essential upgrades. These are critical investments in safety, machine protection, and performance.

First and foremost is the polycarbonate safety door. This is non-negotiable. Mulching creates high-speed projectiles, and a minimum 1/2-inch thick polycarbonate door is vital to protect the operator from serious injury. We insist on proper operator protection.

Comprehensive operator protection also includes ensuring your machine has proper FOPS (Falling Object Protective Structure) and ROPS (Roll Over Protective Structure) certifications for added safety.

The case drain line is another essential upgrade. It returns excess fluid from high-flow attachments to the hydraulic tank, preventing pressure buildup that can damage the mulcher’s motor. Skipping this can lead to expensive repairs.

Finally, an auxiliary hydraulic cooler is often necessary. Continuous high-flow operation generates significant heat that can overwhelm a standard cooling system. An auxiliary cooler prevents overheating, which is crucial on hot Wisconsin summer days. This prevents reduced performance and premature wear on components.

ESSENTIAL MAINTENANCE FOR YOUR MULCHER ATTACHMENT

A forestry mulcher for a skid steer is rugged, but requires regular care to perform reliably. At Kelbe Brothers Equipment, we know that following heavy equipment maintenance best practices is the key to longevity and performance.

Fortunately, most maintenance is straightforward. A few minutes of daily attention and regular service will keep your mulcher operating at peak efficiency.

DAILY INSPECTIONS

Before starting your New Holland compact track loader, perform a quick daily walk-around inspection. This can catch small problems before they become major issues.

Start with the teeth on the rotor or disc and inspect them for wear, cracks, or damage. A single damaged tooth can throw the rotor out of balance and cause strain. Replace or rotate any questionable teeth immediately to avoid larger problems.

Next, inspect all hydraulic hoses and fittings with the machine off. Look for rubbing, cuts, bulges, or leaks, and ensure all fittings are snug. A blown hose can bring a job to a complete halt.

Clear away any debris from the mulcher body, rotor, and motor area, as buildup can trap heat and interfere with parts. Also, check replaceable skid shoes for wear, as this affects cutting height and can lead to frame damage.

ROUTINE SERVICE AND PARTS REPLACEMENT

In addition to daily checks, perform routine service regularly, especially during periods of heavy use.

Grease all bearing points. The rotor spins under heavy load, and proper lubrication is critical for bearing life. Greasing every fitting regularly prevents costly replacements.

For belt-driven disc mulchers, check drive system tension. Incorrect tension can cause power loss or premature wear on belts and bearings. Follow the manufacturer’s guidelines for proper adjustment.

Rotate or replace teeth based on wear. Many teeth can be rotated to use a fresh cutting edge, extending their life. Replace worn-out teeth promptly. Using quality skid steer parts is crucial, as inferior parts wear faster and reduce efficiency.

Maintain your carrier machine as well. Keep the hydraulic fluid in your New Holland or Takeuchi at the proper level and change filters on schedule. Clean hydraulic fluid is essential for keeping the mulcher’s motor and the entire system running cool.

CONCLUSION: TRANSFORM YOUR LAND CLEARING OPERATIONS

A forestry mulcher for skid steer is more than just an attachment; it’s a game-changer for land clearing. This powerful tool transforms thick vegetation into nutrient-rich mulch in a single pass, offering best efficiency.

We’ve covered its applications from forestry management to new construction, the differences between drum and disc mulchers, and key performance features like cutting teeth and hydraulic systems. We also stressed the importance of matching the mulcher to your New Holland or Takeuchi loader and performing crucial safety upgrades and maintenance.

At Kelbe Brothers Equipment, we see how these machines empower contractors to tackle tough projects efficiently while protecting the environment. By understanding your machine’s hydraulic needs, using the right safety gear, and performing diligent maintenance, you can open up the full potential of your forestry mulcher for skid steer.

For contractors across Wisconsin—from Milwaukee and Madison to Green Bay, Butler, and De Pere—we are more than an equipment provider; we are your trusted partners. We offer the best equipment backed by deep expertise to help you conquer any land clearing challenge. If you’re looking for new or used construction equipment for sale in Wisconsin, we have the tools and knowledge to help you succeed. Let us help you transform your land clearing operations.